Ionized hydrogen peroxide comprehensive plasma sterilization technology

A technology of ionizing hydrogen peroxide and plasma, applied in the field of sterilization, can solve the problems of long cycle period, high equipment cost, low use cost, etc., and achieve the effect of ensuring safety, uniform particle size and stable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

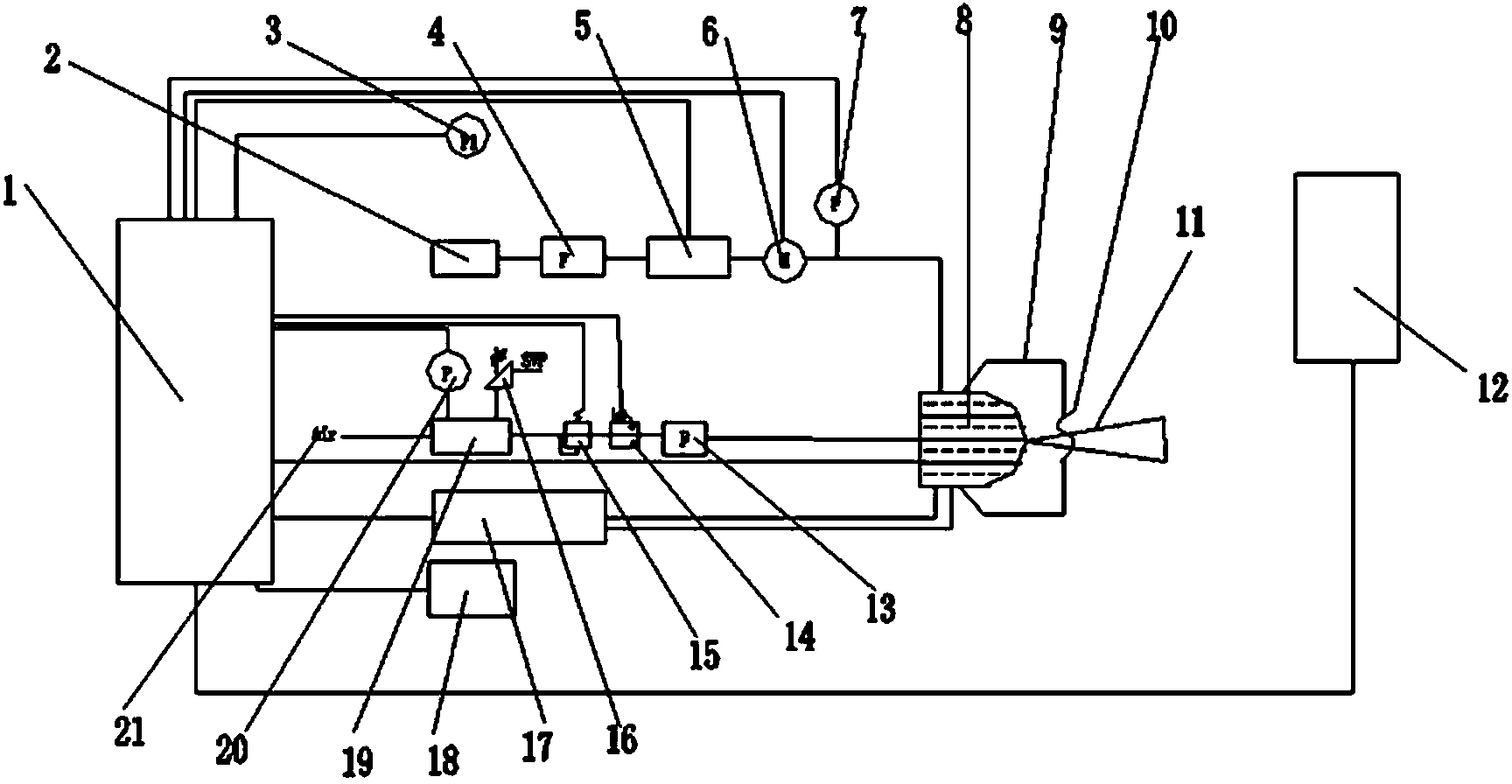

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0020] refer to figure 1 , the specific embodiment adopts the following technical solutions: the mechanical structure of ionized hydrogen peroxide comprehensive plasma sterilization technology includes a controller 1, a liquid storage bottle 2, a proximity sensor 3, a liquid filter 4, a liquid sensor 5, a pump 6, a pressure Sensor 7, atomizer 8, ion generating electrode 9, high arc 10, atomization column 11, external sensor 12, filter 13, pressure detector 14, regulating pressure reducer 15, safety pressure relief valve 16, plasma Generator module 17, device sensor 18, buffer component 19, carrier gas pressure detector 20 and carrier gas system 21, controller 1 respectively communicate with liquid sensor 5, pump 6, pressure sensor 7, atomizer 8, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com