Magnesium-containing hydroxyapatite coating on surface of medical material and preparation method of coating

A magnesium-containing hydroxyapatite and coating technology, applied in the fields of coating, medical science, prosthesis, etc., can solve the problems of long implantation and fixation period, and achieve the goal of regulating growth, regulating remodeling, and inducing bone tissue regeneration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

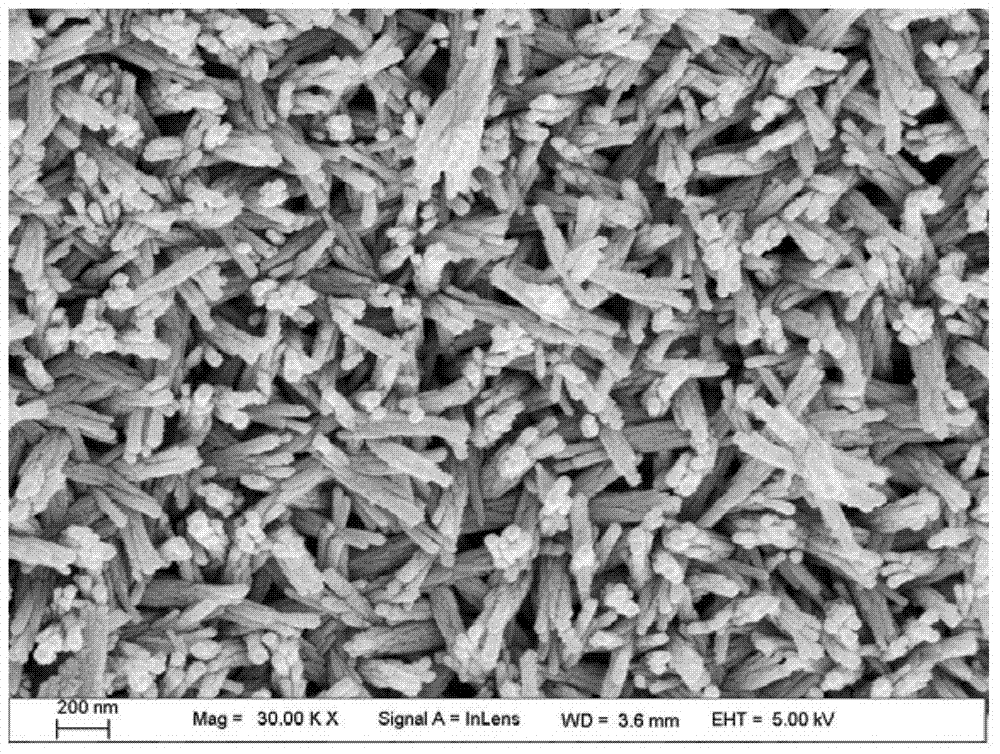

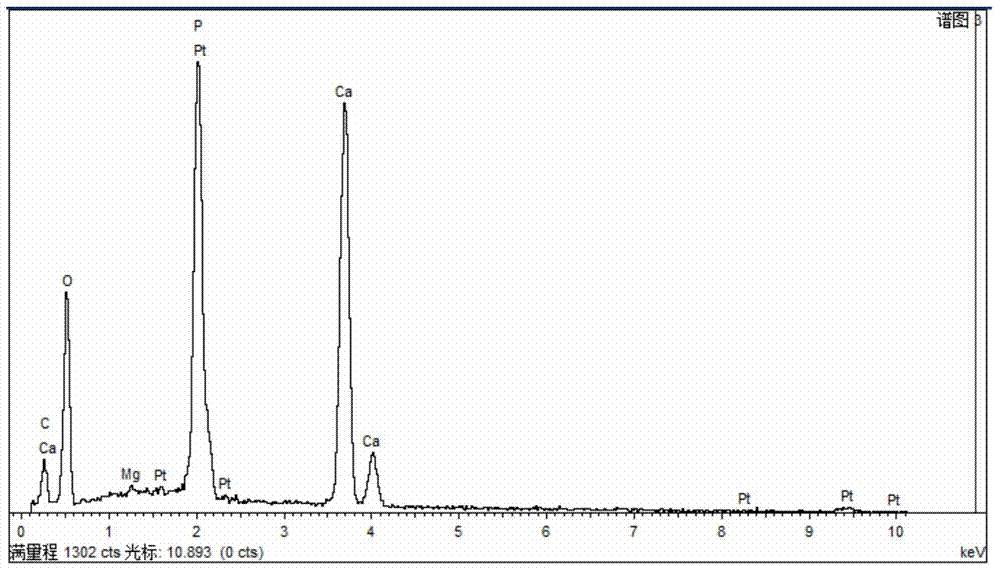

[0031] Add 30% hydrogen peroxide to the hydrothermal kettle to make the density 1.3g / cm 3 The medical carbon / carbon composite material was placed in a hydrothermal kettle for hydrothermal treatment. The hydrothermal treatment temperature was 85°C, the treatment time was 4h, cooled naturally, washed with deionized water and dried; 0.16mol / L calcium nitrate, 0.02mol / L L magnesium nitrate and 0.1mol / L ammonium dihydrogen phosphate are prepared as a mixed solution, and the medical carbon / carbon composite material after hydrothermal treatment is placed in the mixed solution, and a magnesium-doped apatite coating is prepared on its surface by electromagnetic induction , the electromagnetic induction oscillation frequency is 1.1MHz, the oscillation current is 200A, the deposition time is 10min, and is cleaned with deionized water; the magnesium-doped apatite coating is placed in a hydrothermal kettle containing 0.1% ammonia water for hydrothermal treatment. The heat treatment tempera...

Embodiment 2

[0033] Add 30% hydrogen peroxide to the hydrothermal kettle to make the density 1.8g / cm 3 The medical carbon / carbon composite material was placed in a hydrothermal kettle for hydrothermal treatment. The hydrothermal treatment temperature was 145°C, and the treatment time was 24h. It was cooled naturally, washed with deionized water and dried; 0.16mol / L calcium nitrate, 0.1mol / L magnesium nitrate and 0.1mol / L ammonium dihydrogen phosphate are prepared as a mixed solution, and the medical carbon / carbon composite material after hydrothermal treatment is placed in the mixed solution, and a magnesium-doped apatite coating is prepared on its surface by electromagnetic induction , the electromagnetic induction oscillation frequency is 1.1MHz, the oscillation current is 700A, the deposition time is 8h, and cleaned with deionized water; the magnesium-doped apatite coating is placed in a hydrothermal kettle containing 2% ammonia water for hydrothermal treatment, and the water The heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com