Preparation method and application of extractant for heavy metals in sludge

A technology of heavy metals and extractants, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of long treatment period, high operation cost, poor heavy metal removal effect, etc., and meet the requirements of Requirements for heavy metal content, the effect of reducing the content of heavy metal elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the sludge heavy metal extractant of the present invention specifically carries out according to the following steps:

[0026] Step 1, weighing the raw materials according to the proportion, wherein the ratio of each raw material to the dissolved solute in distilled water is 8-15% of polyaluminum chloride, 0.3-0.6% of polyacrylamide, 1.8-2.4% of ethylenediaminetetraacetic acid, dodecyl Sodium sulfonate 1.0-2.0%, the rest is distilled water.

[0027] Step 2: Dissolve the solid raw materials in step 4 in step 1 with distilled water to prepare polyaluminum chloride (PAC) solution, ethylenediaminetetraacetic acid (EDTA) solution, polyacrylamide and sodium dodecylsulfonate respectively The mixed solution (PAM+SDS) of the three solutions; the preparation process is stirred at a speed of 80-100 rpm, heated, and the temperature of the solution is controlled between 25-30°C until there is no obvious precipitation in the solution.

[0028] Step 3, mix t...

Embodiment 1

[0045] Weigh the raw materials according to the following proportions: 8% polyaluminum chloride, 0.6% polyacrylamide, 2.4% ethylenediaminetetraacetic acid, 1.5% sodium dodecylsulfonate, and the rest is solvent distilled water. The total amount of the above components is 100%. Three solutions of PAC, EDTA and PAM+SDS were prepared respectively. During the preparation process, the mixture was stirred at a speed of 80 rpm, and heated, and the temperature of the solution was controlled at 25° C. until there was no obvious precipitation in the solution, and the three prepared solutions were mixed. During the mixing process, stir at a speed of 95 rpm, heat appropriately, and control the temperature of the solution at 28°C. Adjust the pH of the solution prepared in step 3 to 10 with NaOH solution to obtain the sludge heavy metal extractant.

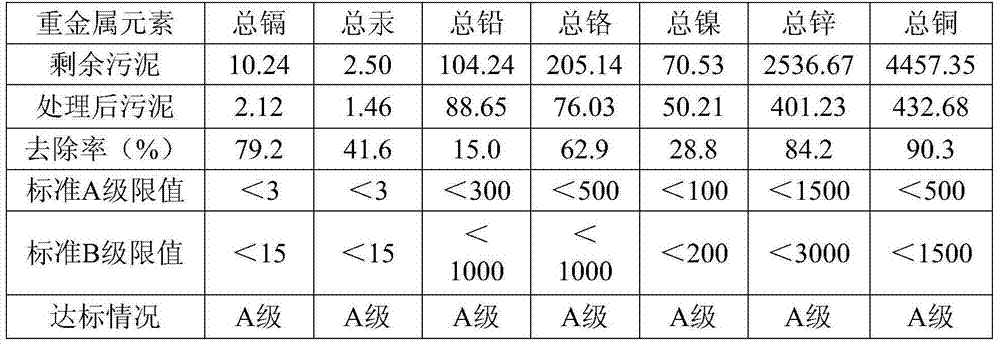

[0046] Use the prepared sludge heavy metal extractant for sludge treatment. First, the sludge is pre-concentrated to reduce the water content o...

Embodiment 2

[0053] Weigh the raw materials according to the following proportions: 15% polyaluminum chloride, 0.5% polyacrylamide, 1.8% ethylenediaminetetraacetic acid, 1.0% sodium dodecylsulfonate, and the rest is solvent distilled water. The total amount of the above components is 100%. Three solutions of PAC, EDTA and PAM+SDS were prepared respectively. During the preparation process, the mixture was stirred at a speed of 90 rpm, heated, and the temperature of the solution was controlled at 28° C. until there was no obvious precipitation in the solution, and the three prepared solutions were mixed. During the mixing process, stir at a speed of 85 rpm, heat appropriately, and control the temperature of the solution at 30°C. Adjust the pH of the solution prepared in step 3 to 9 with NaOH solution to obtain the sludge heavy metal extractant.

[0054] Use the prepared sludge heavy metal extractant for sludge treatment. First, the sludge is pre-concentrated to reduce the water content of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com