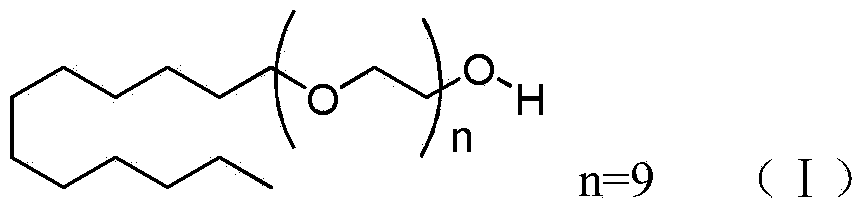

Lauromacrogol refinement method

A refining method, the technology of lauromacrogol, which is applied in the field of medicine and chemical industry, can solve the problems affecting the safety and effectiveness of lauromacrogol, and achieve the effects of simple operation, improved product quality and high refining yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

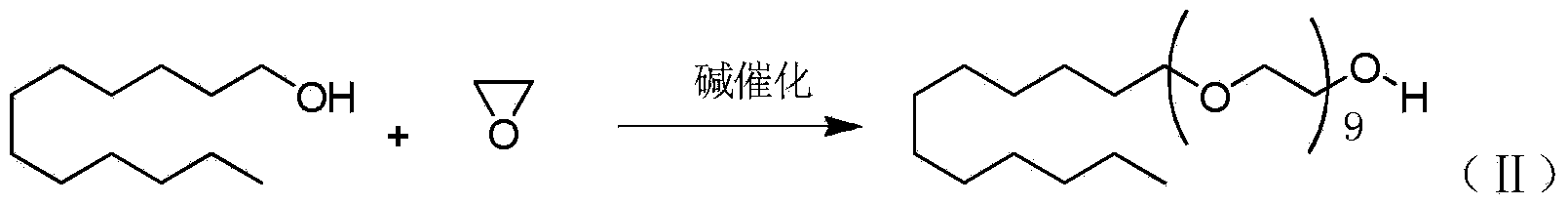

Method used

Image

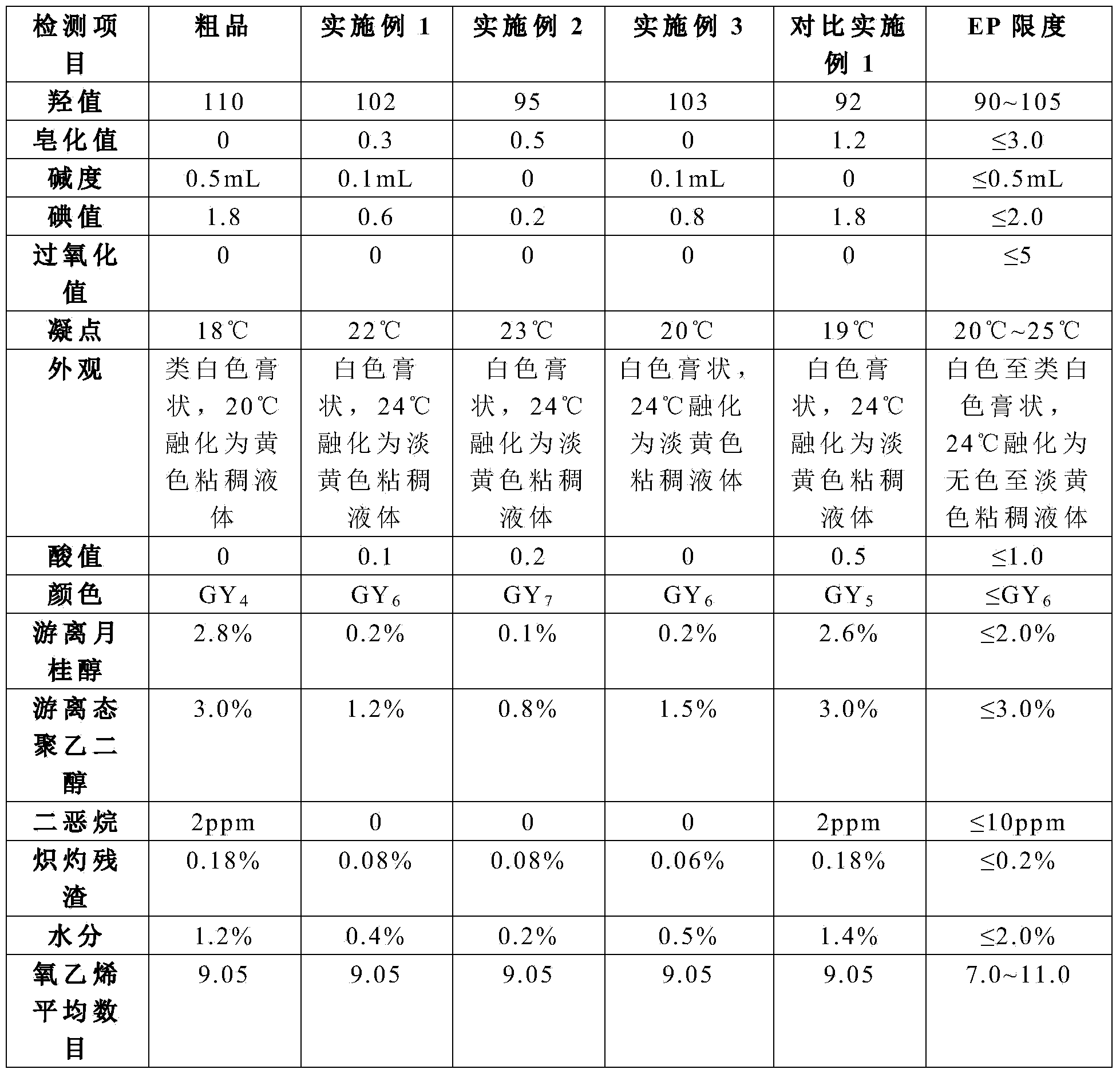

Examples

Embodiment 1

[0025] a. Add 2.8kg of crude lauryl alcohol (the content of lauryl alcohol is 2.8%) into the reaction kettle, raise the temperature to 50°C, start stirring, program the temperature to 130°C, the heating rate is 2°C / min, and decompress at the same time Distillation operation. After the temperature reaches 130°C, continue vacuum distillation for 3 hours, and control the pressure at -0.08Mpa;

[0026] b. Naturally cool the above crude product to 90°C in the reaction kettle, and filter through a filter screen to obtain a light yellow viscous clear filtrate;

[0027] c. Cool the filtrate to 60°C naturally, and adjust the pH value of the system to about 7.0 with phosphoric acid while stirring the filtrate.

[0028] d. Continue to stir, carry out temperature programming at a rate of 2°C / min, and carry out vacuum distillation operation at the same time, the pressure is controlled at -0.08Mpa, after the temperature reaches 80°C, continue vacuum distillation for 2 hours to obtain the f...

Embodiment 2

[0030] a. Add 2.8kg of crude lauryl alcohol (the content of lauryl alcohol is 2.8%) into the reaction kettle, raise the temperature to 50°C, start stirring, program the temperature to 150°C, the heating rate is 20°C / min, and decompress at the same time Distillation operation. After the temperature reaches 150°C, continue vacuum distillation for 0.5 hours, and control the pressure at -0.08Mpa;

[0031] b. Naturally cool the above-mentioned crude product to 100°C in a reaction kettle, and filter through a filter screen to obtain a light yellow viscous clear filtrate;

[0032] c. Cool the above filtrate to 80°C naturally, and adjust the pH value of the system to about 7.5 with acetic acid while stirring the filtrate.

[0033] d. Continue to stir, carry out temperature program at a rate of 20°C / min, and carry out vacuum distillation operation at the same time, control the pressure at -0.08Mpa, after the temperature reaches 150°C, continue vacuum distillation for 0.5 hours to obta...

Embodiment 3

[0035] a. Add 2.8kg of crude lauryl alcohol (the content of lauryl alcohol is 2.8%) into the reaction kettle, raise the temperature to 50°C, start stirring, program the temperature to 130°C, the heating rate is 10°C / min, and decompress at the same time Distillation operation. After the temperature reaches 130°C, continue vacuum distillation for 9 hours, and control the pressure at -0.09Mpa;

[0036] b. Naturally cool the above crude product to 80°C in the reaction kettle, and filter through a filter screen to obtain a light yellow viscous clear filtrate;

[0037] c. Cool the above filtrate to 40°C naturally, and adjust the pH value of the system to about 7.5 with propionic acid while stirring the filtrate.

[0038] d. Continue to stir, carry out temperature programming at a rate of 10°C / min, and carry out vacuum distillation operation at the same time, the pressure is controlled at -0.08Mpa, after the temperature reaches 100°C, continue vacuum distillation for 10 hours to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com