Production method of ascorbyl glucoside

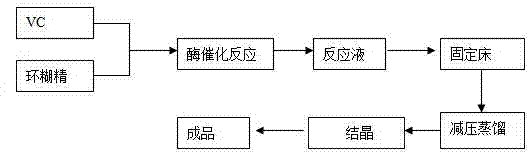

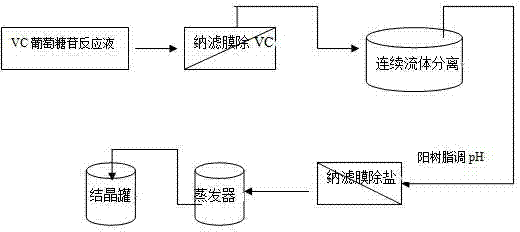

A technology of ascorbyl glucoside and production method, which is applied in the direction of sugar derivatives, sugar derivatives, separation methods, etc., can solve the problems of high cost and low yield, and achieve the effects of compact equipment, reduced dosage, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

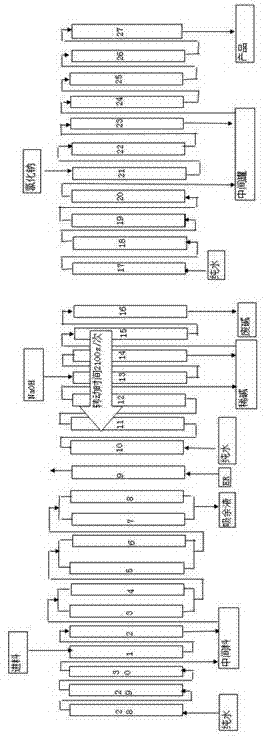

[0053] Embodiment: The raw material liquid is the material liquid after removing VC by nanofiltration, and the material liquid is yellow, wherein the content of VC glucoside is about 5%, and the content of glucose is about 20%. The rotation period of the equipment is 2100s or 35min. The flow rate of the resin = 450 / 35 = 12.8mL / min, and the feed volume of the reaction liquid is about 138mL. The amount of resin can be characterized by the ratio of resin volume to feed volume, that is, 12.8:138=1:10.8. In the case of 2100S / rev, the amount of feed liquid that can be processed by a unit of resin is: 10.8ml feed liquid / ml resin; Method carries out the result of VC glucoside production as follows:

[0054]

[0055] Table 2 Continuous fluid adsorption and desorption experimental data

[0056] It should be noted that, the present embodiment only uses the continuous ion exchange system of 30 separation units as an example to describe the technical effect that the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com