Heat-transfer heat-accumulation medium prepared by combining quartz sand and multi-composition molten nitrate salt and preparation method

A heat storage medium, quartz sand technology, applied in chemical instruments and methods, heat exchange materials, energy input, etc., can solve the problems of increased corrosion, increased maintenance costs, no quartz sand, etc., to achieve high Fire resistance, low industrial cost, improved thermal stability and the effect of upper limit use temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

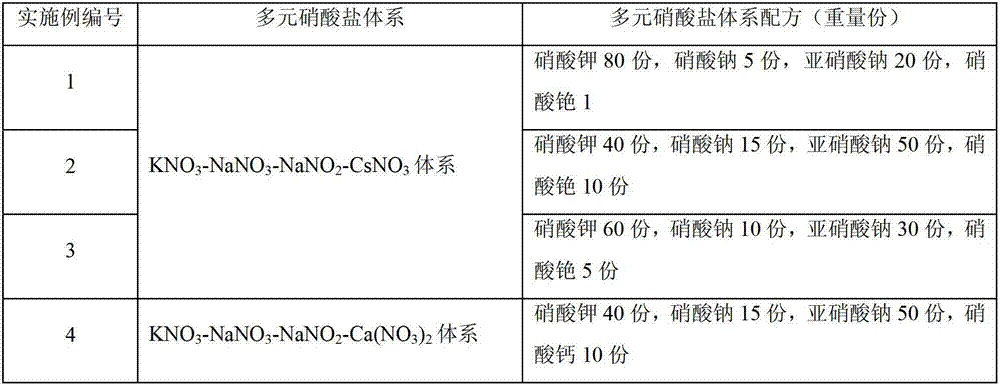

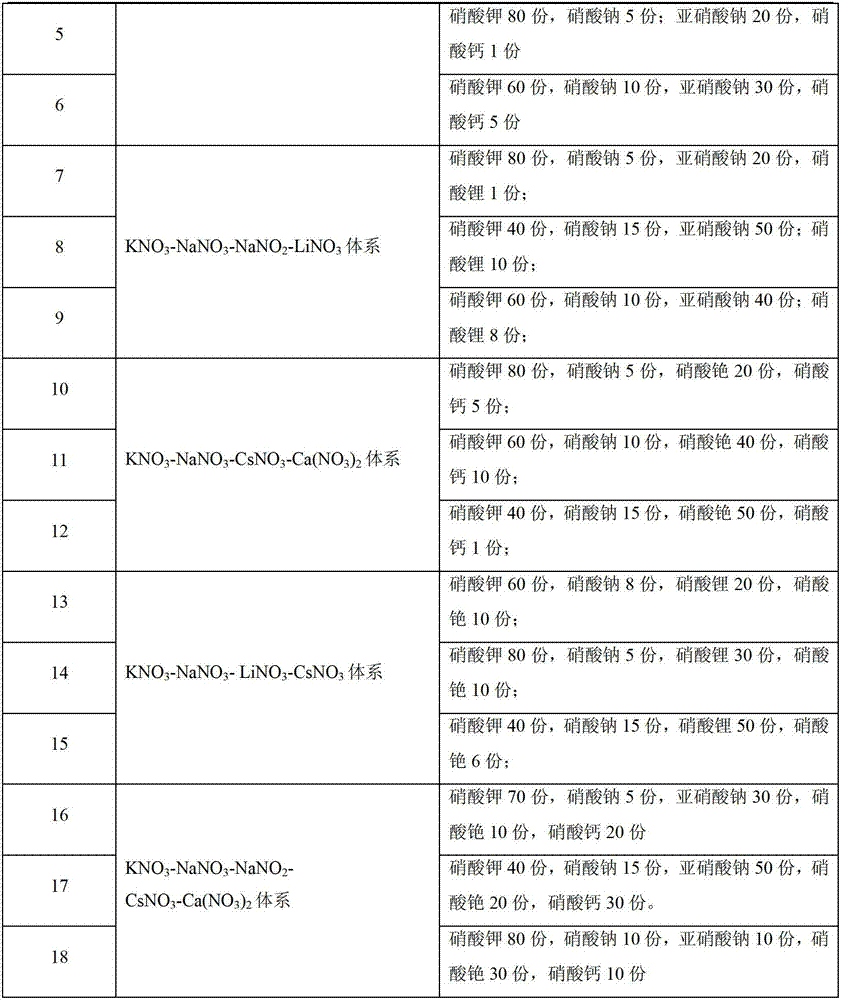

[0043] Embodiment 1~3. Multivariate nitrate system KNO 3 -NaNO 3 -NaNO 2 -CsNO 3 Adding quartz sand to prepare heat storage and heat transfer medium

[0044] Step 1. Preparation of quartz sand composite multi-element nitric acid molten salt products 1~3:

[0045] The formula listed in table 1 is prepared to form the material of multi-component nitric acid molten salt system, after heating and stirring evenly, add quartz sand, continue heating and stirring, to degas and dewater, heating temperature is 80-120 ℃ above the molten salt phase transition temperature.

[0046] Disperse quartz sand (100 mesh) into the molten multi-component nitric acid molten salt system, and stir the molten mixture for 1-2 hours to obtain a quartz sand composite multi-component nitric acid molten salt heat transfer and heat storage medium. Quartz sand accounts for 1%, 20%, and 50% of products 1~3 respectively.

[0047] Step 2. Thermal stability test of products 1~3

[0048] The thermal stability t...

Embodiment 4~6

[0058] Embodiment 4~6 multi-component nitrate system KNO 3 -NaNO 3 -NaNO 2 -Ca(NO 3 ) 2 Adding quartz sand to prepare heat storage and heat transfer medium

[0059] According to the formula listed in Table 1, prepare the materials to form the multi-component nitric acid molten salt system.

[0060] The preparation method and detection method of product 4~6 are completely the same as embodiment 1~3, and quartz sand (100 orders) accounts for 10%, 25%, 40% respectively; The contrast does not contain quartz sand, is embodiment 4~6 in table 1 corresponding system.

[0061] Thermal stability measurement result is similar to embodiment 1~3, after being incubated at 700 DEG C for 30 hours, the loss rate of three kinds of products prepared by the present invention is successively about 10%, 3%, 1%, obviously lower than contrast Up to 28%.

[0062] It is carried out with a common differential scanner DSC (scanning is performed under normal pressure). The test results show that, ...

Embodiment 7~9

[0063] Embodiment 7~9. Multivariate nitrate system KNO 3 -NaNO 3 -NaNO 2 -LiNO 3 Adding quartz sand to prepare heat storage and heat transfer medium

[0064] The formula listed in table 1 is prepared to form the material of multivariate nitric acid molten salt system

[0065] Preparation method and detection method are completely the same as embodiment 1~3.

[0066] The quartz sand (100 order) that embodiment 7~9 adds accounts for 15%, 30%, 45%

[0067] Thermal stability measurement result is similar to embodiment 1 ~ 3, after being incubated at 700 DEG C for 30 hours, the loss rate of three kinds of products prepared by the present invention is the highest 12%, 4%, 2%, obviously lower than the 30% of contrast. %.

[0068] It is carried out with a common differential scanner DSC (scanning is performed under normal pressure). The test results show that, compared with the control, the melting points of products 7-9 are basically unchanged, and the latent heat of phase cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com