Technological process and equipment for central gas supply by biomass gasification pyrolysis

A technological process and biomass technology, applied in the field of biomass gasification pyrolysis centralized gas supply process and equipment, can solve the problems of environmental pollution, effective utilization rate less than 20%, waste of plant resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described below are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

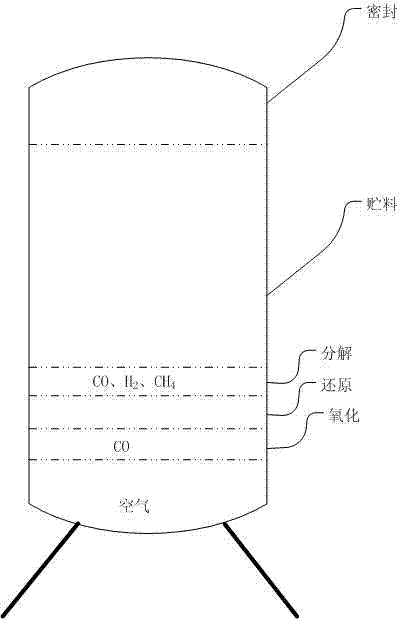

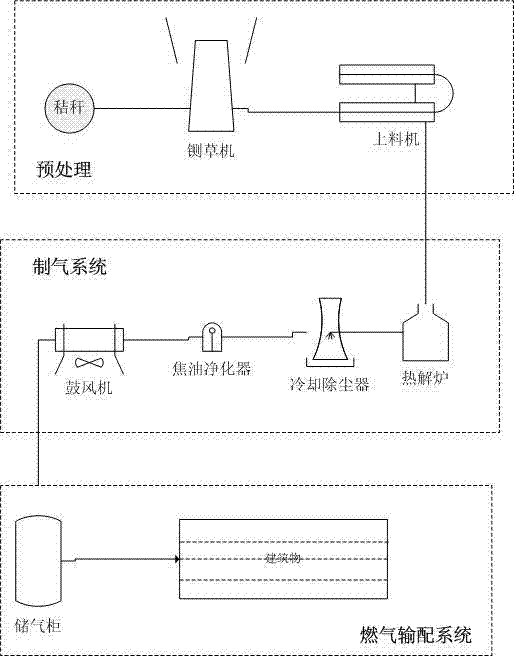

[0011] figure 1 It is the flow chart of the concentrated gas supply process of straw pyrolysis gasification provided by the present invention:

[0012] First, the straw is cut into small pieces with a hay cutter, and the straw is sent into the pyrolysis furnace with a feeder. The straw is converted into combustible gas through pyrolysis and gasification reaction in the pyrolysis furnace, and the gas contained in the gas is removed in the purifier. Impurities such as dust and tar are sent to the gas storage cabinet by the blower. The gas storage cabinet provides a constant pressure to balance the fluctuation of the gas load to ensure the stable combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com