Rapid solidification aluminum alloy material and preparation method thereof

An aluminum alloy material and aluminum alloy technology, applied in the field of rapid solidification aluminum alloy material and its preparation, can solve the problems of high quality, unfavorable sodium-sulfur battery assembly, handling, thermal conductivity and electrical conductivity need to be improved, stainless steel is expensive, etc., to achieve The effect of low price, easy processing and molding, high strength and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

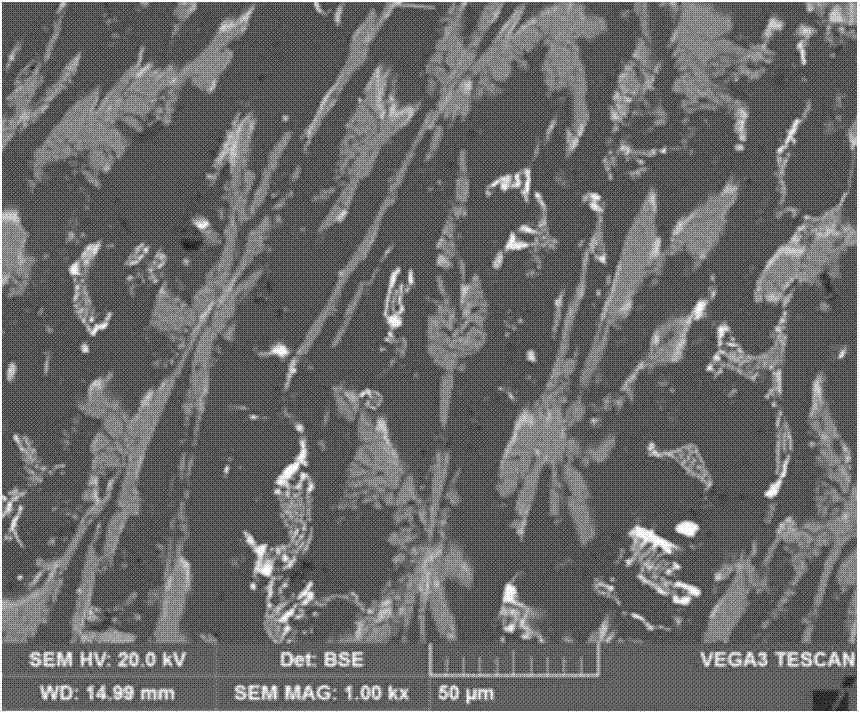

[0037] Pure aluminum ingots with a purity of not less than 99.5wt%, pure iron rods, and blocky lanthanum-cerium mixed rare earths (see Table 1 for composition) are formulated into Al-20Fe and Al-10Re master alloys in appropriate mass percentages. 5 kg; use medium frequency induction furnace to melt Al-20Fe master alloy, and use well type crucible resistance furnace to melt Al-10Re master alloy. Then, according to the composition ratio of Al-8Fe-4Re, take an appropriate amount of pure aluminum ingots and Al-Fe master alloys and place them in an intermediate frequency induction furnace, and then add Al-Re master alloys after melting, and mix them evenly with electromagnetic stirring, and then pour and cool The as-cast Al-8Fe-4Re alloy was obtained by demolding, and the SEM image is as follows figure 2 shown. The alloy ingots obtained by smelting are broken, and the broken block alloys are placed in acetone solution and alcohol solution for ultrasonic cleaning, taken out and dr...

Embodiment 2

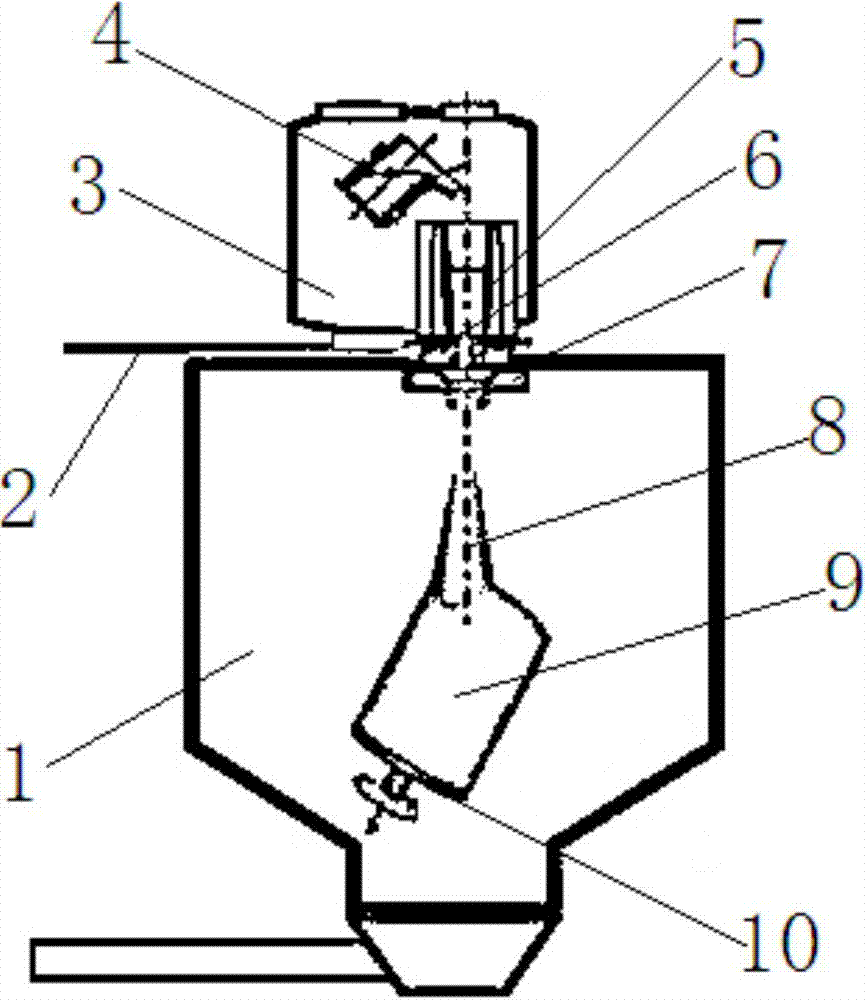

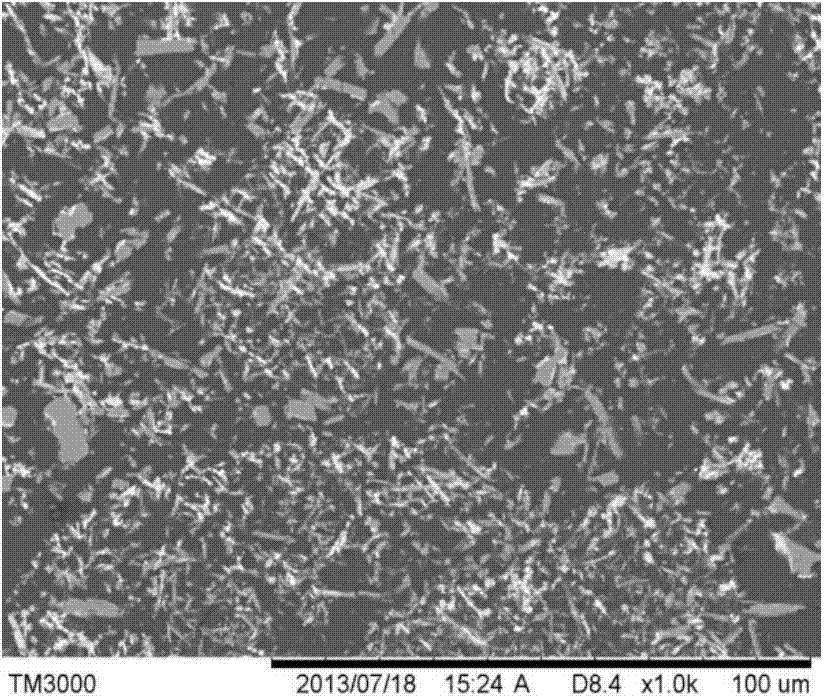

[0052] Prepare pure aluminum ingots with a purity of not less than 99.5wt%, pure iron rods, and blocky lanthanum-cerium mixed rare earths with appropriate mass percentages to prepare master alloys divided into Al-20Fe and Al-10Re, each weighing 5 kg; use intermediate frequency The Al-20Fe master alloy is smelted in an induction furnace, and the Al-10Re master alloy is smelted in a well-type crucible resistance furnace. Then according to the composition ratio of Al-8Fe-4Re, take an appropriate amount of Al-Fe master alloy and place it in a medium-frequency induction furnace. After melting, add Al-Re master alloy and mix it evenly with electromagnetic stirring. After that, cast it by pouring, cooling and demolding Al-8Fe-4Re alloy ingot. The alloy ingots obtained by smelting are broken, and the broken block alloys are placed in acetone solution and alcohol solution for ultrasonic cleaning, taken out and dried naturally; the cleaned block alloys are placed in a large-scale atomiz...

Embodiment 3

[0060] Pure aluminum ingots with a purity of not less than 99.5wt%, pure iron rods, and blocky lanthanum-cerium mixed rare earths are formulated with appropriate mass percentages into Al-20Fe and Al-10Re master alloys, each weighing 5 kg; using intermediate frequency induction The Al-20Fe master alloy is smelted in the furnace, and the Al-10Re master alloy is smelted in the well-type crucible resistance furnace. Then according to the composition ratio of Al-8Fe-4Re, take an appropriate amount of Al-Fe master alloy and place it in a medium-frequency induction furnace. After melting, add Al-Re master alloy and mix it evenly with electromagnetic stirring. After that, cast it by pouring, cooling and demolding Al-8Fe-4Re alloy ingot. The alloy ingots obtained by smelting are broken, and the broken block alloys are placed in acetone solution and alcohol solution for ultrasonic cleaning, taken out and dried naturally; the cleaned block alloys are placed in a large-scale atomized depo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com