RF cables for marine engineering

A radio frequency cable and marine engineering technology, applied in circuits, electrical components, waveguide devices, etc., can solve the problems of cracking, affecting the normal operation of the cable, damage to the outer sheath of the cable, etc., to achieve good chemical stability, increase toughness, use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

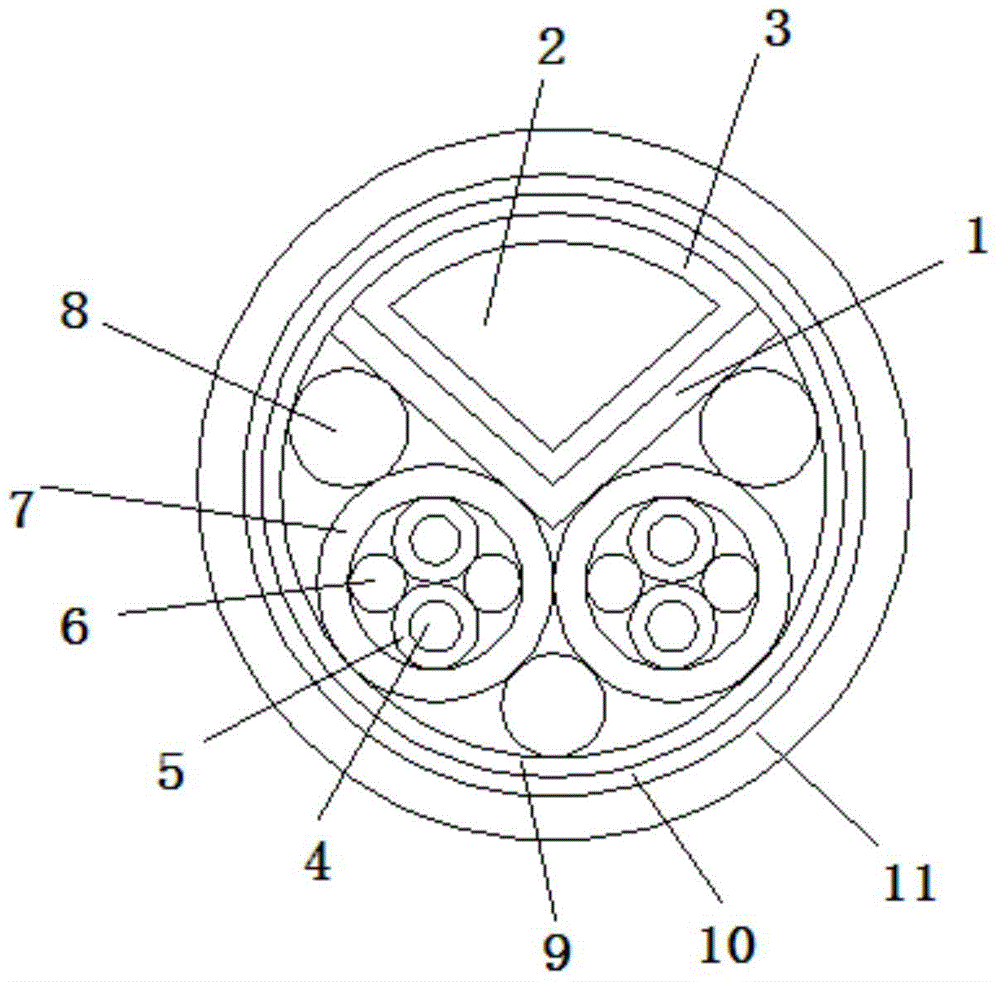

[0016] Such as figure 1 As shown, a radio frequency cable for marine engineering includes a cable core, the cable core includes a V-shaped rubber skeleton 1, and a fan-shaped main conductor 2 is placed above the V-shaped rubber skeleton 1, and the main conductor 2 is extruded with fluorine Plastic insulation layer 3, two control wire cores are placed under the V-shaped rubber skeleton 1, the control wire cores include two control conductors 4 wrapped with silicone rubber insulation layer 5, two control conductors 4 and two thermoplastic polyurethane elastic The body 6 is stranded and extruded with a cross-linked polyethylene insulating layer 7 , and the cable core is stranded with three filling ropes 8 and then covered with a wrapping layer 9 , a water blocking layer 10 and an outer sheath 11 in sequence.

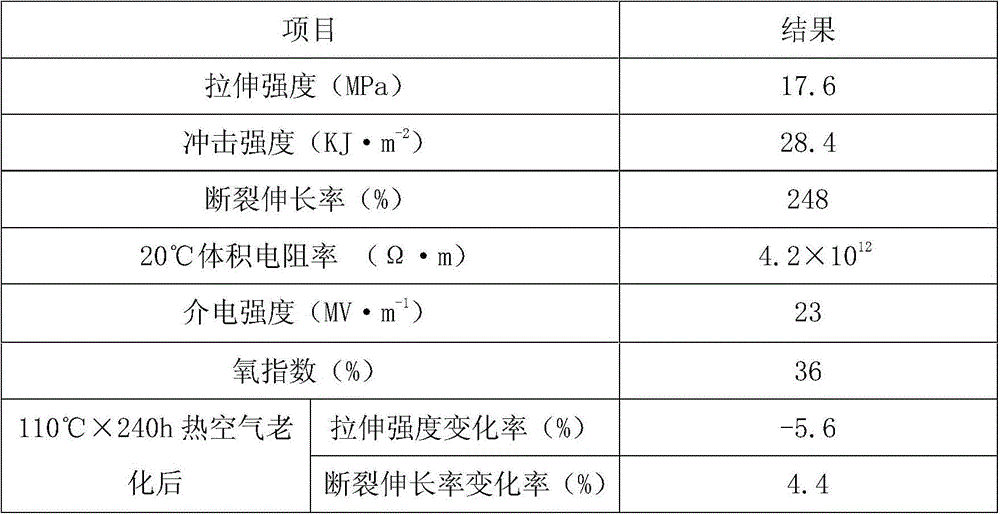

[0017] The material of the outer sheath 11 is made of the following raw materials in parts by weight: chlorinated polyvinyl chloride 70, 2,2-bis(4-hydroxyphenyl)propane pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com