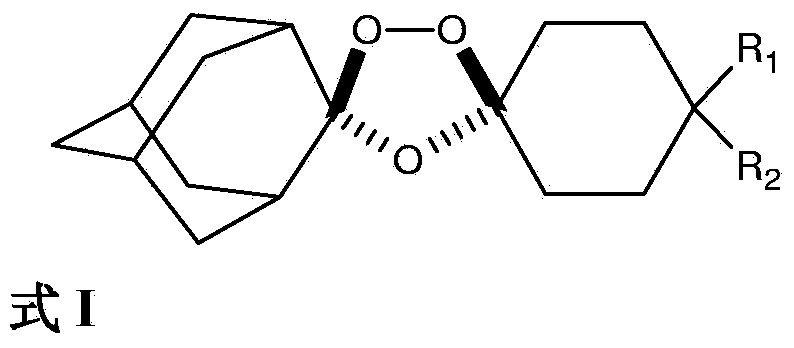

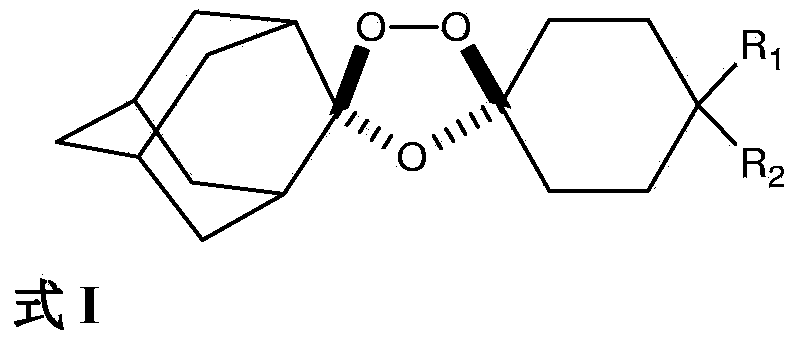

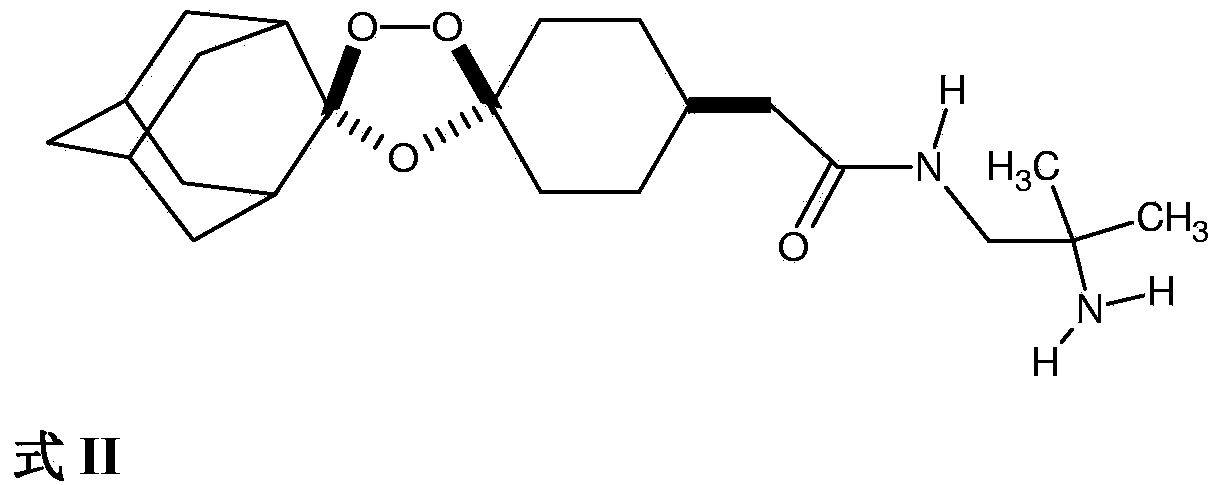

Stable dosage forms of arterolane and piperaquine

A stable, dosage-form technology, applied in the field of stable dosage forms of artemisinin and piperaquine, which can solve problems such as poor efficacy, reduced efficacy, and poor compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0162]

[0163] process:

[0164] 1. Sieve Active Compound I with the intragranular portion of microcrystalline cellulose through a sieve BSS #44 and mix in a double cone mixer to form a homogeneous mixture.

[0165] 2. Add the sieved intragranular portion of the magnesium stearate to the mixture of step 1 and mix for about 5 minutes.

[0166] 3. Compact the mixture from step 2 in a roller compactor, then sieve through a BSS #22 sieve to form granules.

[0167] 4. Sieve the microcrystalline cellulose, croscarmellose sodium and magnesium stearate of the extragranular fraction through a sieve BSS#44 and blend with the granules from step 3.

[0168] 5. The mixture of step 4 is compressed using a punching machine of appropriate size to obtain compressed tablets.

[0169] 6. The tablets obtained in step 5 are coated with Perform coating.

[0170] The tablets prepared in Example 1 were subjected to a stability study for 6 months at 25°C / 60% relative humidity, 30°C / 65% rela...

Embodiment 2

[0179]

[0180] process:

[0181] 1. Sieve Active Compound I, microcrystalline cellulose, croscarmellose sodium and magnesium stearate through sieve BSS #44.

[0182] 2. Mix the sieved Active Compound I, microcrystalline cellulose and croscarmellose sodium in a double cone mixer for about 15 minutes to form a homogeneous mixture.

[0183] 3. Add the sieved magnesium stearate to the mixture from step 2 and mix for approximately 5 minutes.

[0184] 4. The mixture obtained in step 3 is directly compressed using capsule-shaped punches of appropriate size to obtain compressed tablets.

Embodiment 3 and 4

[0186]

[0187]

[0188] process:

[0189] 1. Sieve the intragranular fraction of Active Compound I, piperaquine phosphate and microcrystalline cellulose and cross-linked polyvinylpyrrolidone through a sieve BSS #44, then mix in a double cone mixer to form a homogeneous mixture.

[0190] 2. Add the intragranular portion of the sieved magnesium stearate to the mixture of step 1 and mix for about 5 minutes.

[0191] 3. The mixture from step 2 was compacted in a roller compactor, then sieved through a BSS #18 sieve to form granules.

[0192] 4. Sieve the microcrystalline cellulose and cross-linked polyvinylpyrrolidone in the extragranular portion through a sieve BSS#44, then mix with the granules from step 3.

[0193] 5. Sieve the magnesium stearate extragranular portion through a sieve BSS #44 and blend with the mixture from step 4 in a double cone blender for about 5 minutes.

[0194] 6. The blend of step 5 is compressed using appropriate sized punches to obtain compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com