Binary ordered colloidal crystal, metal nano array and preparation method thereof

A technology of colloidal crystals and metal nanometers, applied in the field of nanomaterials, can solve problems such as not being suitable for industrial production, and achieve the effects of low cost, stable process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

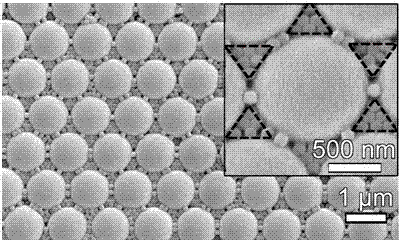

[0056] Mix 150 μL of polystyrene nanosphere emulsion with a particle size of 1100 nm (mass fraction 5%) and 10 μL of polystyrene emulsion with a particle size of 120 nm (mass fraction 5%) to form a mixed emulsion. The same volume of absolute ethanol (160 μL) in the mixed emulsion was heated and ultrasonically mixed, the ultrasonic time was 20 min, the heating temperature was 40 °C, and the power was 100 W.

[0057] The silicon wafer substrate was soaked in acetone and absolute ethanol successively, ultrasonicated for 10 min, soaked in SDS for 24 h, and then the substrate was taken out, rinsed with deionized water, and blown dry with nitrogen.

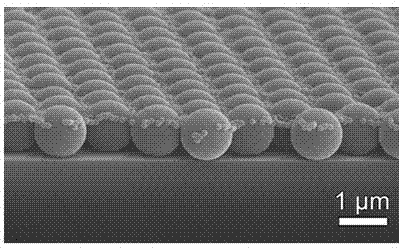

[0058] Immediately drop the emulsion mixed evenly by ultrasonic waves onto the glass drainage sheet, then drain it to the surface of deionized water, slowly and evenly drop 50 μL of the mixed emulsion within 30 minutes, and the emulsion quickly self-assembles into a binary system at the interface between deionized water and air. Colloid...

Embodiment 2

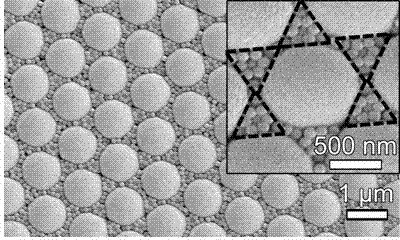

[0061] Mix 110 μL of polystyrene nanosphere emulsion with a particle size of 1100 nm and 10 μL of polystyrene nanosphere emulsion with a particle size of 120 nm (5% mass fraction) to form a mixed emulsion, and add the same volume as the mixed emulsion Anhydrous ethanol (120 μL) was heated and ultrasonically mixed, the ultrasonic time was 20 min, the heating temperature was 40°C, and the power was 100W.

[0062] The silicon wafer substrate was soaked in acetone and absolute ethanol successively, ultrasonicated for 10 min, soaked in SDS for 24 h, and then the substrate was taken out, rinsed with deionized water, and blown dry with nitrogen.

[0063] Immediately drop the solution evenly mixed by ultrasound onto the glass drainage sheet, and drain it to the surface of deionized water. The mixed solution quickly self-assembles into a binary colloidal crystal film at the interface between deionized water and air, and slowly and evenly drop it within 30 minutes. 50 μL mixed solution,...

Embodiment 3

[0066] Mix 60 μL emulsion of polystyrene nanospheres with a particle size of 800 nm (mass fraction 5%) and 10 μL emulsion of polystyrene nanospheres with a particle size of 260 nm (mass fraction 5%), and add to the emulsion The same volume of absolute ethanol (70 μL) was heated and ultrasonically mixed, the heating ultrasonic time was 20 min, the heating temperature was 40 °C, and the power was 100 W.

[0067] The silicon wafer substrate was soaked in acetone and absolute ethanol successively, ultrasonicated for 10 min, soaked in SDS for 24 h, and then the substrate was taken out, rinsed with deionized water, and blown dry with nitrogen.

[0068] Immediately drop the solution evenly mixed by ultrasound onto the glass drainage sheet, and drain it to the surface of deionized water. The mixed solution quickly self-assembles into a binary colloidal crystal film at the interface between deionized water and air, and slowly and evenly drop it within 30 minutes. 50 μL of mixed solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystal size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com