Low-temperature SCR smoke denitration catalyst of carbon nano tube load metallic oxide and preparation method thereof

A denitrification catalyst and metal-loaded technology, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem that the catalyst is easy to be washed and blocked by dust, and the service life is reduced etc. to achieve the effect of strong corrosion resistance, improved adsorption, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

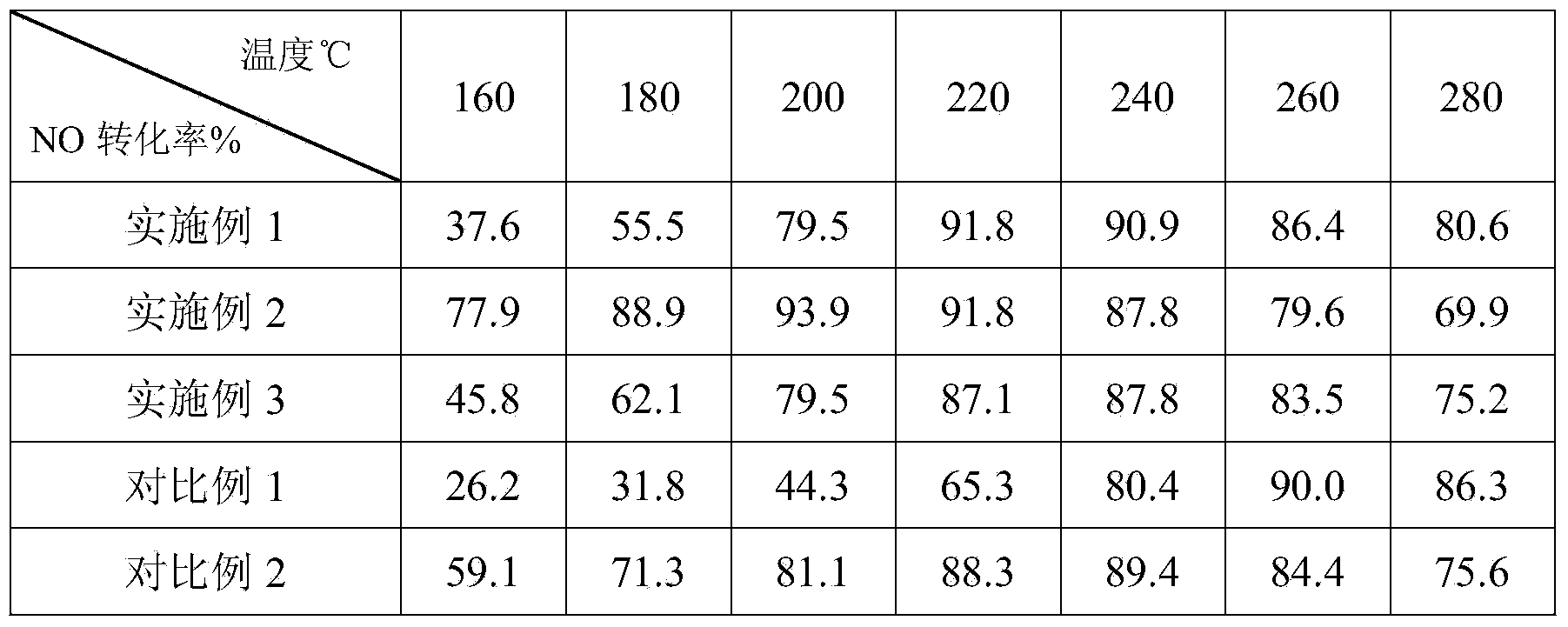

Examples

Embodiment 1

[0030] (1) Pretreatment of carbon nanotubes: Weigh 1g of multi-walled carbon nanotubes into a conical flask, add 200ml of 3mol / L nitric acid solution, treat with ultrasonic waves for 30min, then bathe in water at 100°C for 4h, filter and wash with water until neutral. Dry at 110°C for 12h, then place the acid-treated multi-walled carbon nanotubes in a dielectric barrier discharge (DBD) reactor at 25ml / min O 2 In the atmosphere, discharge at 45KV for 40min. That is, pretreated multi-walled carbon nanotubes are obtained.

[0031] (2) ZrO 2 Preparation of / MWCNTs composite carrier: Weigh 0.33g of zirconyl nitrate and dissolve it in 20ml of absolute ethanol, and drop evenly into 1g of pretreated multi-walled carbon nanotubes. Ultrasonic treatment of the above mixed material for 30min, then drying in an ordinary blast drying oven at 60°C for 12h, and then drying in a tube furnace for N 2 Roasting at 400°C under atmosphere (heating rate 5°C / min, holding time 2h, ZrO 2 / MWCNTs co...

Embodiment 2

[0034] (1) Pretreatment of MWCNTs: Weigh 1g of multi-walled carbon nanotubes into a conical flask, add 200ml of 3mol / L nitric acid solution, treat with ultrasonic wave for 30min, then place in water bath at 100℃ for 4h, filter and wash with water until neutral, and 110℃ After drying for 12 h, the acid-treated MWCNTs were placed in a dielectric barrier discharge (DBD) reactor at 25 ml / min O 2 In the atmosphere, discharge at 45KV for 40min. That is, the pretreated MWCNTs are obtained.

[0035] (2) ZrO 2 Preparation of / MWCNTs composite carrier: Weigh 0.98g of zirconyl nitrate and dissolve it in 20ml of absolute ethanol, and drop evenly into 1g of pretreated multi-walled carbon nanotubes. Ultrasonic treatment of the above mixed material for 30min, then drying in an ordinary blast drying oven at 60°C for 12h, and then drying in a tube furnace for N 2 Roast at 400°C under atmosphere (heating rate 5°C / min, holding time 2h) to get ZrO 2 / MWCNTs composite carrier, in which ZrO 2 Th...

Embodiment 3

[0038] (1) Pretreatment of carbon nanotubes: Weigh 1g of multi-walled carbon nanotubes into a conical flask, add 200ml of 3mol / L nitric acid solution, treat with ultrasonic waves for 30min, then bathe in water at 100°C for 4h, filter and wash with water until neutral. Dry at 110°C for 12h, then place the acid-treated MWCNTs in a dielectric barrier discharge (DBD) reactor at 25ml / min O 2 In the atmosphere, discharge at 45KV for 40min. That is, pretreated multi-walled carbon nanotubes are obtained.

[0039] (2) ZrO 2 Preparation of / MWCNTs composite carrier: Weigh 1.63g of zirconyl nitrate and dissolve it in 20ml of absolute ethanol, and drop evenly into 1g of pretreated MWCNTs. Ultrasonic treatment of the above mixed material for 30min, then drying in an ordinary blast drying oven at 60°C for 12h, and then drying in a tube furnace for N 2 Roast at 400°C under atmosphere (heating rate 5°C / min, holding time 2h) to get ZrO 2 / MWCNTs catalyst, where ZrO 2 The ratio to the mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com