Method for manufacturing contact lens and method for monitoring eye pressure by using contact lens

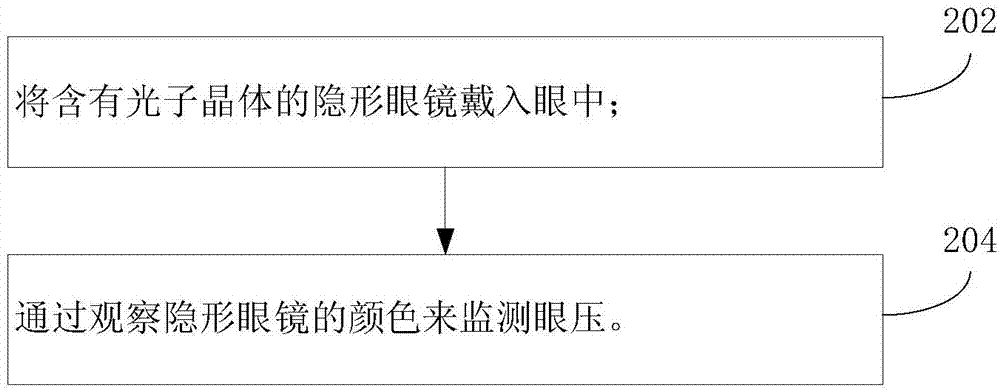

A contact lens and intraocular pressure technology, applied in tonometers, applications, household appliances, etc., can solve the problems of unaffordable, inability to real-time intraocular pressure monitoring, and complex structure design for middle and low-level groups, achieving low cost and improving vision. Deteriorating, simple-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

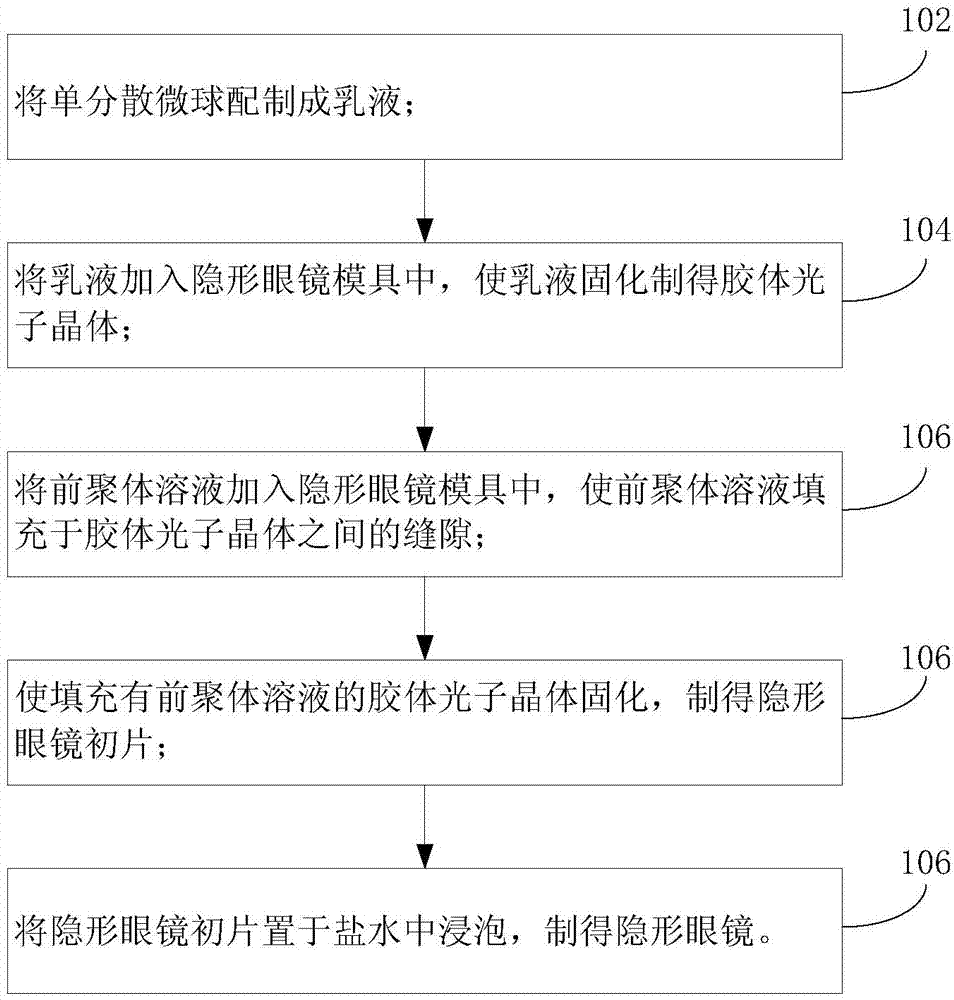

[0033] Such as figure 1 Shown, the preparation method of the contact lens of the present application, one embodiment thereof, comprises the following steps:

[0034] Step 102: Formulate the monodisperse microspheres into an emulsion.

[0035] Disperse the monodisperse colloidal nanoparticles in water and configure to obtain a colloidal emulsion with a mass fraction of 0.001% to 10%. Monodisperse microspheres include polystyrene, polymethyl methacrylate, silicon dioxide, titanium dioxide, iron oxide, ferric oxide, gold and silver, or any combination of more. Specifically, it can be microspheres of polystyrene, polymethyl methacrylate, silicon dioxide, titanium dioxide, iron oxide, ferric oxide, gold, silver, or polystyrene, polymethyl methacrylate, di Modified microspheres of silicon oxide, titanium dioxide, iron oxide, iron oxide, gold, silver, or polystyrene, polymethyl methacrylate, silicon dioxide, titanium dioxide, iron oxide, iron oxide, gold , Silver composite microsp...

Embodiment 1

[0061] 1. Preparation of colloidal photonic crystal particles:

[0062] 10 mL of monodisperse polystyrene microspheres with a diameter of 180 nm were formulated into an emulsion with a mass concentration of 5.0 wt%, dispersed ultrasonically, and then added to the mold used to prepare contact lenses, and the mold was placed in an oven at 50 °C In 30 minutes, you can get up and down through the colloidal crystals.

[0063] 2. Curing treatment of prepolymer solution:

[0064] 100 microliters of contact lens prepolymer mixture: methyl methacrylate (95% by mass), ethylene glycol dimethacrylate (4.8% by mass) and UV initiator Irgacure 2959 (mass fraction: 0.2%) into the mold, let it stand for 30 minutes until the prepolymer fully infiltrates the colloidal crystal, and then UV cross-linking at 0 degrees Celsius for 1 hour, that is, the initial contact lens product is cured.

[0065] 3. Hydration treatment of contact lenses:

[0066] After demolding the initial product of the conta...

Embodiment 2

[0068] 1. Preparation of colloidal photonic crystal particles:

[0069] 10 mL of monodisperse silica microspheres with a diameter of 220 nanometers were formulated into an emulsion with a mass concentration of 0.1 wt%, dispersed ultrasonically, and then added to the lower mold used to prepare contact lenses, and the lower mold was left to stand at 50 °C oven for 30 minutes to obtain the penetrating colloidal crystals.

[0070] 2. Curing treatment of prepolymer solution:

[0071] Add 100 microliters of the contact lens prepolymer mixture: the mixed solution of hydroxyethyl methacrylate and methylene bisacrylamide (molar ratio 30:1), and add Irgacure 2959 (mass concentration: 0.2%) as the initiator Put it into the mold, let it stand for 30 minutes until the prepolymer fully infiltrates the colloidal crystal, and then perform ultraviolet crosslinking at 0 degrees Celsius for 1 hour, and then the initial contact lens product is cured.

[0072] 3. Hydration treatment of contact l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com