A kind of preparation method of white carbon black

A white carbon black and water glass solution technology, applied in the direction of silica, silicon oxide, etc., can solve the problems of difficult dispersion and easy agglomeration of silica, and achieve the effect of solving agglomeration, simple equipment requirements, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

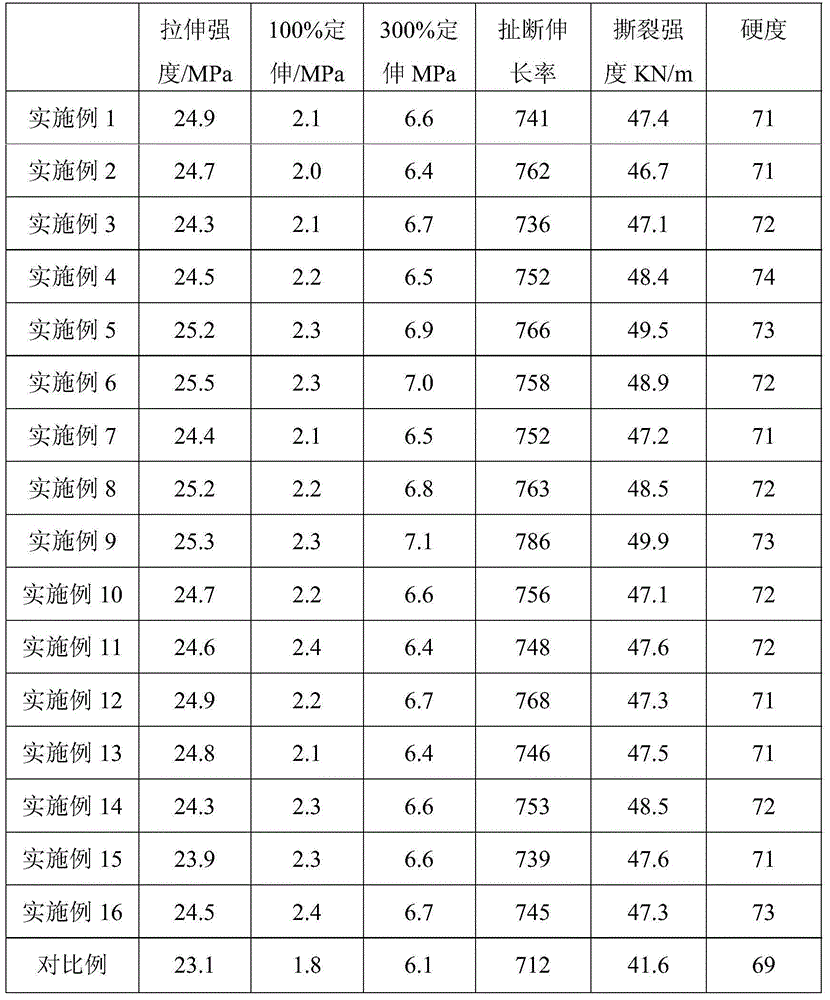

Examples

Embodiment 1

[0026] Add water to the water glass solution with a modulus of 3.8 to prepare 1000 g of water glass solution with a mass fraction of 10%, add 0.2 g of dodecyltrimethylammonium bromide, add 2 g of glutinous rice starch, and stir for 30 minutes under heating at 70 ° C , the stirring rate is 100m / min, and after fully stirring, it is passed into the spray drying tower to react in situ with the gas containing 50% carbon dioxide (the other 50% is air). The inlet temperature of the spray dryer is 300°C, and the outlet temperature is 90°C. The atomized particle size is 5 microns. After spray drying, the finished product of starch-modified silica is carbonized on a curing bed at 200°C. The new silica is mixed with rubber according to the specified formula and vulcanized to measure its mechanical properties.

Embodiment 2

[0028] Add water to the water glass solution with a modulus of 2.4 to prepare 1000 g of water glass solution with a mass fraction of 15%, add 0.5 g of tetradecyltrimethylammonium bromide, add 10 g of cornstarch, and stir at 68 ° C for 30 min , the stirring rate is 150m / min, fully stirred and passed into the spray drying tower to react in situ with the gas containing 20% carbon dioxide (the other 80% is nitrogen), the inlet temperature of the spray dryer is 200°C, the outlet temperature is 70°C, the fog The particle size is 10 microns. After spray drying, the finished product of starch modified silica is obtained. After granulation, it is carbonized on a curing bed at 180°C. The new silica is mixed with rubber according to the specified formula and vulcanized to measure its mechanical properties.

Embodiment 3

[0030] The water glass solution with a modulus of 2.8 was added with water to prepare 1000 g of water glass solution with a mass fraction of 22%, added 1 g of cetyltrimethylammonium bromide, 25 g of tapioca starch, and stirred at 85 ° C for 30 min. The stirring speed is 180m / min. After fully stirring, it is passed into the spray drying tower to react in situ with the gas containing 40% carbon dioxide (the other 60% is air). The inlet temperature of the spray dryer is 500°C, and the outlet temperature is 120°C. The particle size is 30 microns. After spray drying, the starch-modified silica product is obtained. Carbonization is carried out on a drum dryer at 200 ° C. The new silica is mixed with rubber according to the specified formula and vulcanized to measure its mechanical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com