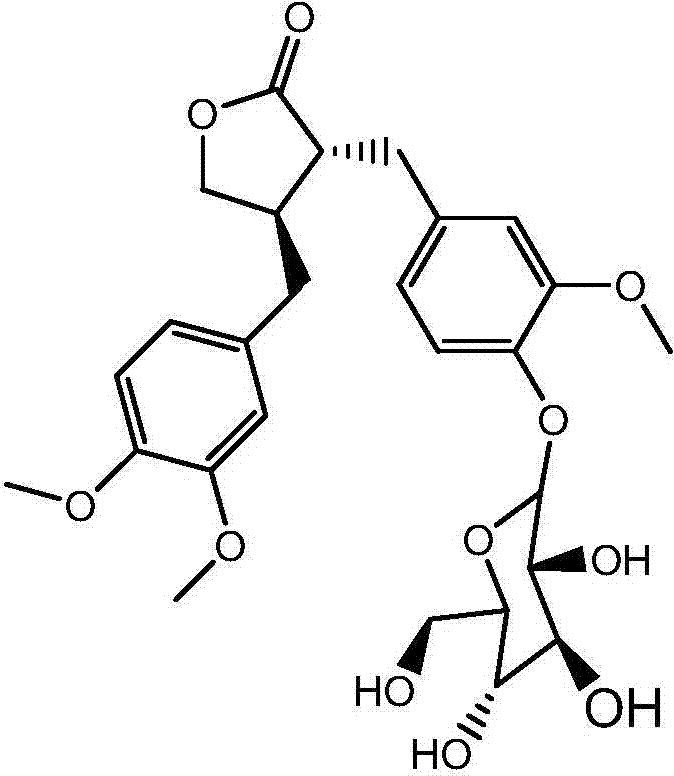

Extraction, separation and purification method of arctiin

A technique for separation and purification of arctiside, applied in chemical instruments and methods, organic chemistry, preparation of sugar derivatives, etc., can solve the problems of high equipment cost, unsuitability for industrialization, difficulty in large-scale production, etc., and achieves easy industrial production, The effect of low production cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take 10kg of crushed burdock fruit, put it into the extraction tank, add 60L of 70% ethanol and aqueous solution, reflux extraction 3 times for 3 hours each time, combine the extract, add 900g of activated carbon, stir and decolorize, filter, concentrate the filtrate to about 35L, add petroleum Ether: Ethyl acetate = 1:2 Stir about 4L to extract impurities, TLC monitoring (conditions: dichloromethane / methanol = 5:1, UV observation, product Rf value = 0.4), repeat extraction 6 times, discard the layer containing impurities . The remaining mother liquor was extracted arctiin with dichloromethane for 5 times, the extracts were combined, concentrated, dissolved in 3L of methanol, and 600ml of isopropyl ether was added for crystallization. About 300g of white crystals were obtained by suction filtration, and the arctiin content was tested to be >98%.

Embodiment 2

[0029] Take 5 kg of crushed burdock seeds, put them into an extraction tank, add 30 L of 95% ethanol and aqueous solution, reflux extraction 3 times for 3 hours each time, combine the extracts, add 450 g of activated carbon, stir to decolorize, filter, concentrate the filtrate to about 18 L, add petroleum Ether: Ethyl acetate = 1:3 Stir about 3L to extract impurities, TLC monitoring (conditions: dichloromethane / methanol = 5:1, UV observation, product Rf value = 0.4), repeat extraction 4 times, discard the layer containing impurities . The remaining mother liquor was extracted with dichloromethane to extract arctiin 8 times, the extracts were combined, concentrated, dissolved in 1.5L of methanol, and 300ml of isopropyl ether was added for crystallization. About 180g of white crystals were obtained by suction filtration, and the arctiin content was tested to be >98%.

Embodiment 3

[0031] Get 10kg of crushed burdock seeds, put it into an extraction tank, add 60L of 75% ethanol and aqueous solution by weight, reflux extraction 3 times for 3 hours each time, combine the extracts, add 900g of activated carbon (stir to decolorize, filter, concentrate the filtrate to about 30L, add petroleum Ether: Ethyl acetate = 1:1 Stir about 4L to extract impurities, TLC monitoring (conditions: dichloromethane / methanol = 5:1, UV observation, product Rf value = 0.4), repeat extraction 5 times, discard the layer containing impurities The remaining mother liquor is extracted with dichloromethane to extract arctiin, extract 8 times, combine the extracts, concentrate, dissolve with 3L of methanol, add 600ml of isopropyl ether to crystallize. Suction filtration obtains about 310g of white crystals, and the content of arctiin after testing > 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com