Bidithiophene-benzobis(benzothiadiazole) copolymer and its preparation method and application

A technology of benzothiadiazole and bidithiophene, which is applied in semiconductor/solid-state device manufacturing, organic chemistry, electric solid-state devices, etc., can solve the problem of low energy conversion efficiency, wide energy bandgap, and reduced photon absorption rate of organic solar cells And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

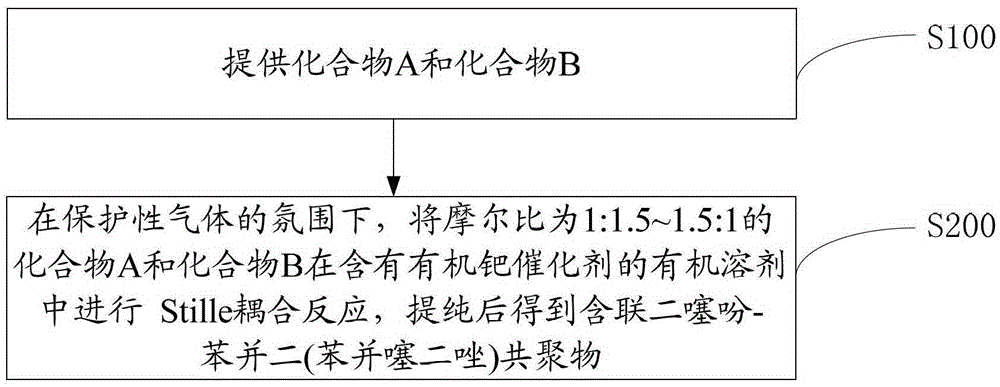

[0042] One embodiment contains the preparation method of bidithiophene-benzobis(benzothiadiazole) copolymer, such as figure 1 shown, including the following steps:

[0043] Step S100, providing compound A and compound B.

[0044] A is: B is: Among them, R 1 , R 2 for C 1 ~C 20 the alkyl group, R 3 , R 4 for H or C 1 ~C 20 of alkyl.

[0045] Wherein the preparation of compound A comprises the following steps:

[0046] Step S111, adding 2-amino-5-nitroaniline to thionyl chloride (SOCl 2 ), add pyridine dropwise while stirring (the structural formula is Molecular formula is C 5 h 5 N,), wherein the solid-to-liquid ratio of 2-amino-5-nitroaniline to pyridine is 3mol:40ml, then heated to 80°C-90°C for reflux reaction for 24 hours, then remove excess thionyl chloride, add after cooling Precipitate with deionized water, collect the solid, wash it and dry it in vacuum to obtain 5-nitro-2,1,3 benzothiadiazole.

[0047] The reaction formula of this step is:

[0048]...

Embodiment 1

[0095] This example discloses poly{2,2'-bithiophene-6,7-bis(3,7-dimethyl)octyl-benzo[2,1-e:3,4-e] with the following structural formula Bis(benzothiadiazole)} (containing bidithiophene-benzobis(benzothiadiazole) copolymer P1):

[0096]

[0097] The preparation process of the above-mentioned bidithiophene-benzobis(benzothiadiazole) copolymer P1 is as follows:

[0098] 1.1. Preparation of compound 5-nitro-2,1,3 benzothiadiazole

[0099]

[0100] Add 2-amino-5-nitroaniline (22.95g, 0.15mol) and 100ml of thionyl chloride into a three-necked flask, stir and slowly add 2ml of pyridine dropwise, heat and then reflux at 80-90°C for 24 hours to stop the reaction , heated to 80°C and rotary evaporated excess SOCl 2 Afterwards, the reaction product was cooled to room temperature, poured into a large amount of water, stirred, filtered, washed with water and then vacuum-dried to obtain 21.7 g of the product 5-nitro-2,1,3-benzothiadiazole with a yield of 80%.

[0101] 1.2. Preparat...

Embodiment 2

[0124] This example discloses poly{4,4'-didecyl-2,2'-bidithiophene-6,7-bis(3,7-dimethyl)octyl-benzo[2, 1-e:3,4-e] bis(benzothiadiazole)} (containing dithiophene-benzobis(benzothiadiazole) copolymer P2):

[0125]

[0126] The preparation process of the above-mentioned bidithiophene-benzobis(benzothiadiazole) copolymer P2 is as follows:

[0127] 2.1, 4,9-dibromo-6,7-bis(3,7-dimethyl)octyl-benzo[2,1-e:3,4-e]bis(benzothiadiazole) Prepare with embodiment 1.

[0128] 2.2. Preparation of 4,4'-didecyl-5,5'-bis(tributyltin base)-2,2'-dithiophene

[0129]

[0130] Under the protection of nitrogen, add 4,4'-didecyl-5,5'-dibromo-2,2'-dithiophene (6.05g, 0.01mol) into the three-necked flask, add 80ml of tetrahydrofuran solvent, Slowly inject n-butyllithium (8.4mL, 2.5M) with a syringe at -78°C, continue stirring for 1h, and inject tributyltin chloride (5.6mL, 0.02mol) with a syringe at -78°C ), was warming up to room temperature and stirred for 6 hours after reacting for 1 hour. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com