A kind of pajama fabric preparation method with composite function

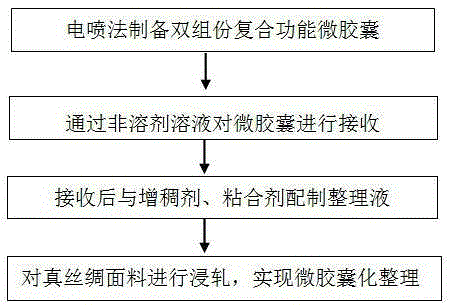

A composite function and fabric technology, applied in the processing of textile materials, continuous processing of textile materials, textiles and papermaking, etc., can solve the problems of reduced comfort, increased microcapsule dosage, and hardened fabric feel to improve durability Performance and washability, good application prospects, and the effect of improving the sustained release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The described receiving solution containing microcapsules adopts the following specific preparation steps:

[0048] a) Prepare a polyurethane wall material solution with a mass fraction of 3.8% in polyurethane wall material and dimethylformamide (DMF) solvent, and add TiO with a mass fraction of 5% 2 -Ag antibacterial agent;

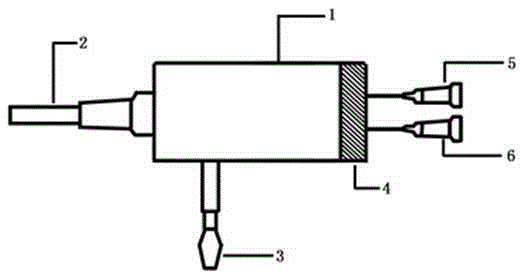

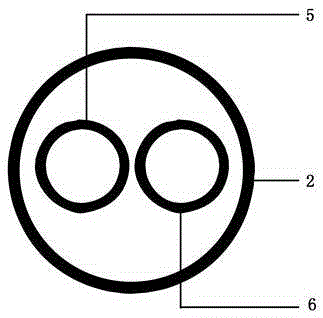

[0049] b) Using the high-voltage electric spraying method, the selected lavender essential oil core material, vitamin E acetate core material and polyurethane wall material solution are subjected to high-voltage electric spraying through the three-way pipe fittings according to the method described in the above step 1.3), and 20Kv DC high voltage is applied static electricity;

[0050] c) Use a micro-injection pump to spray from the needle of the dispensing needle. The flow rate of the external liquid is 1.5mL / h, and the flow rate of the two internal liquids is 0.75mL / h. Distilled water is used for receiving, and the distilled water and the tip o...

Embodiment 2

[0054] The described receiving solution containing microcapsules adopts the following specific preparation steps:

[0055] a) Prepare a polyurethane wall material solution with a mass fraction of 3.3% in polyurethane wall material and dimethylformamide (DMF) solvent, and add TiO with a mass fraction of 3.5% 2 -Ag antibacterial agent;

[0056] b) Using the high-voltage electric spraying method, the selected lavender essential oil core material, vitamin E acetate core material and polyurethane wall material solution are subjected to high-voltage electric spraying through the three-way pipe fittings according to the method described in the above step 1.3), and 16Kv DC high voltage is applied static electricity;

[0057] c) Use a micro-injection pump to spray from the needle of the dispensing needle. The flow rate of the external liquid is 0.5mL / h, and the flow rate of the two internal liquids is 0.25mL / h. Distilled water is used for receiving. Distilled water and the tip of the ...

Embodiment 3

[0061] The described receiving solution containing microcapsules adopts the following specific preparation steps:

[0062] a) Prepare a polyurethane wall material solution with a mass fraction of 3.5% in polyurethane wall material and dimethylformamide (DMF) solvent, and add TiO with a mass fraction of 4% 2 -Ag antibacterial agent;

[0063] b) Using the high-voltage electric spraying method, the selected lavender essential oil core material, vitamin E acetate core material and polyurethane wall material solution are subjected to high-voltage electric spraying through the three-way pipe fittings according to the method described in the above step 1.3), and 10Kv DC high voltage is applied static electricity;

[0064] c) Use a micro-injection pump to spray from the needle of the dispensing needle. The flow rate of the external liquid is 1.2mL / h, and the flow rate of the two internal liquids is 0.5mL / h. Distilled water is used for reception. Distilled water and the tip of the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com