System and method for controlling drill rod stick-slip vibration based on active damping method

A technology of active damping and stick-slip vibration, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc. It can solve the problems of complex hardware connection, unstable system operation, and unsatisfactory realization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be described in detail below with reference to the drawings and specific embodiments.

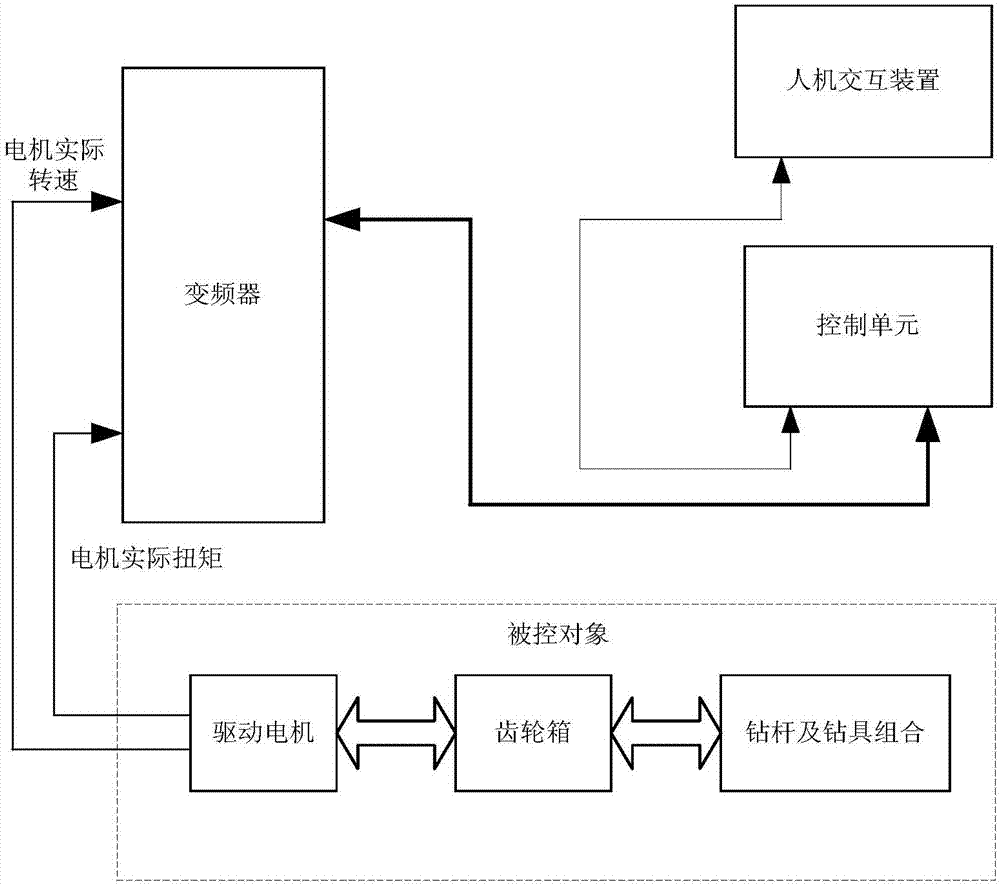

[0072] Such as figure 1 As shown, the system for suppressing stick-slip vibration of drill pipe based on the active damping method of the present invention includes:

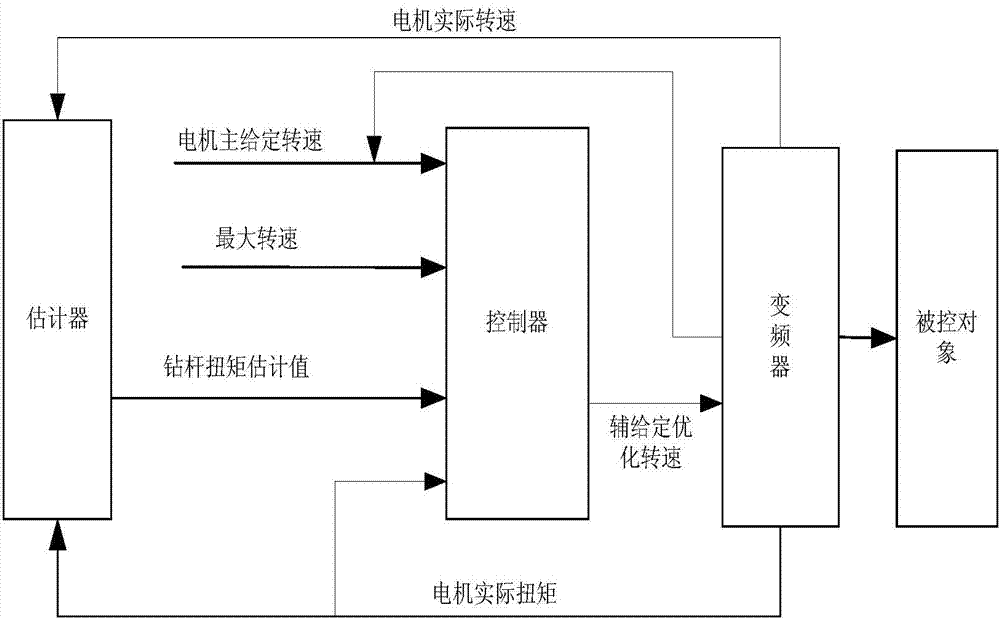

[0073] The controlled object includes the gear box connected to the drive motor, and the drill pipe and drilling tool assembly driven by the gear box, which are used to realize oil drilling; the frequency converter includes the PLC control system. The PLC control system controls the start, stop and Adjust the working state of the speed, and set the fixed speed of the main motor, the inverter will feedback the current state of the drive motor to the control unit; the control unit, including the active damping controller, is used to control and adjust the current state of the drive motor to suppress Torque oscillation and rotational speed oscillation of drill pipe and drill tool assembly; human-mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com