Method for producing high-purity metal chromium by reducing anhydrous chromium chloride through utilizing metal magnesium

A technology of chromium chloride and metal chromium, which is applied in the field of producing high-purity metal chromium, can solve problems such as difficulty in guaranteeing product quality, high cost, complicated vacuum carbon reduction process, etc., and achieves the effect of easy removal and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

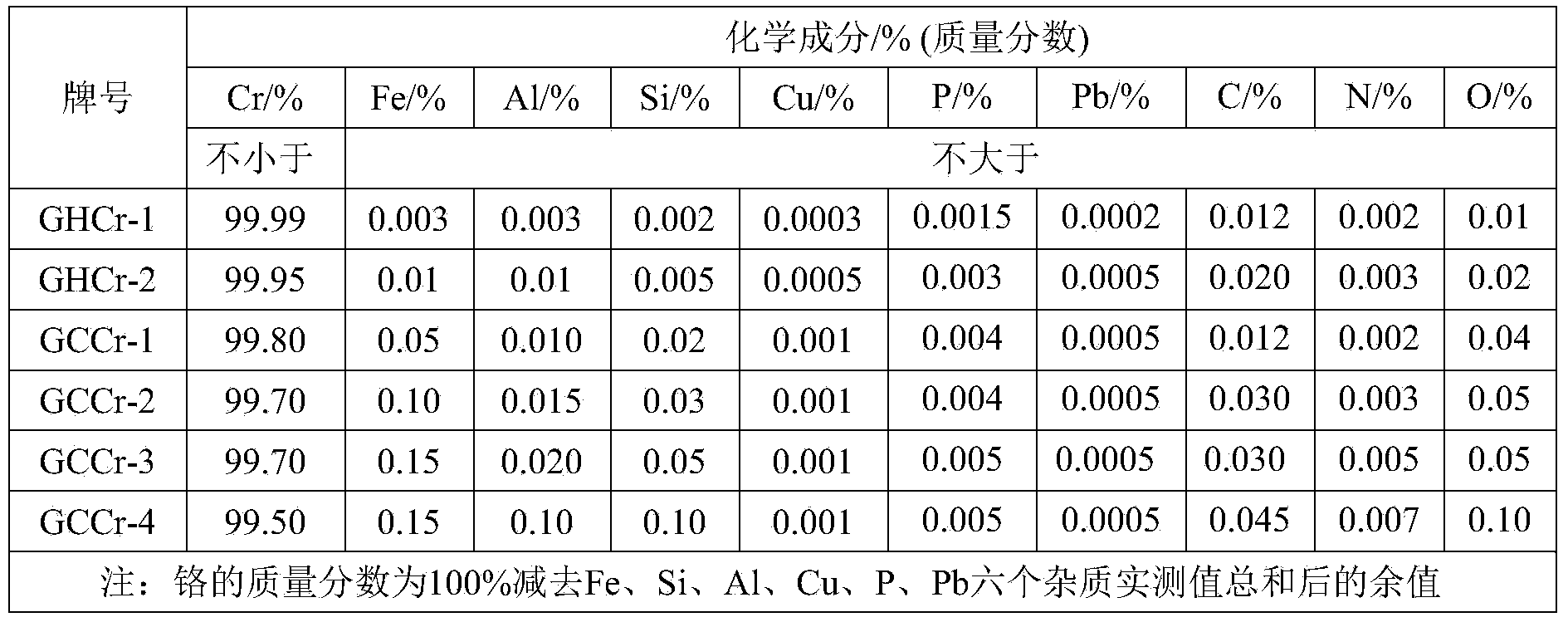

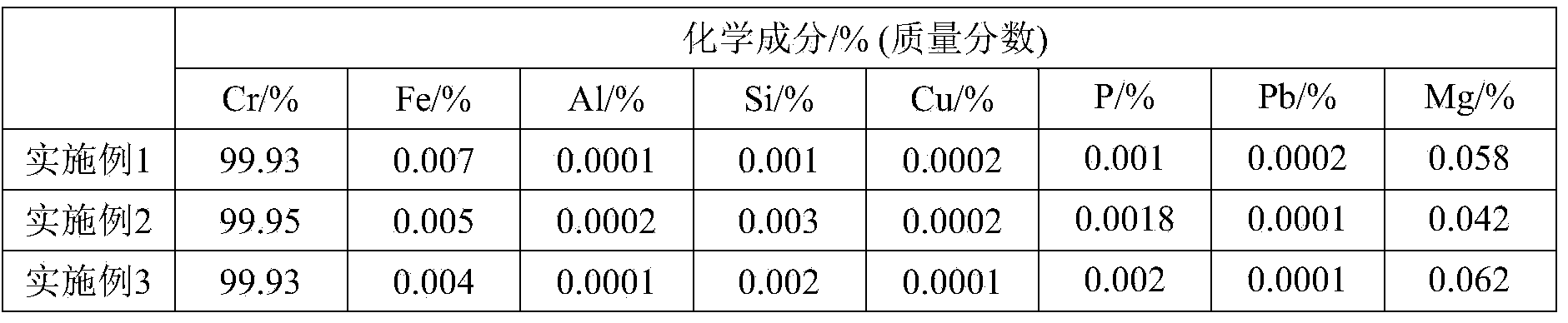

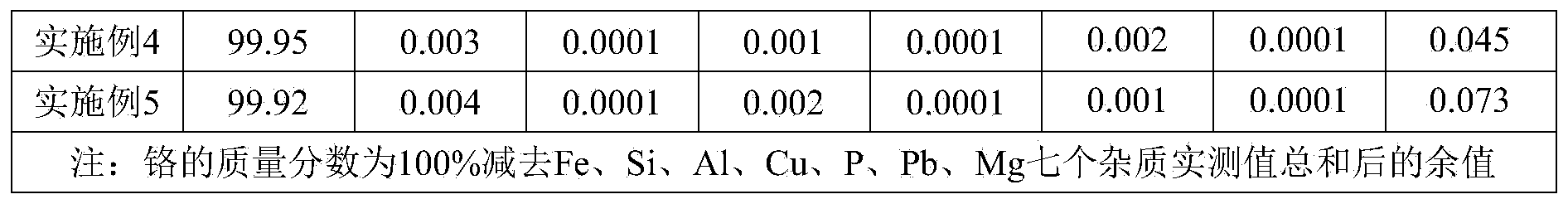

Embodiment 1

[0030] Purify anhydrous chromium chloride by sublimation under the protection of argon; weigh 18g superior pure NaCl, 22g anhydrous MgCl 2 After the anhydrous chromium chloride after 9g purification and 4g99.99% magnesium metal (200% of theoretical quantity) are mixed, place in the metal chromium crucible, then put the metal chromium crucible into the atmosphere furnace protected by argon, Then heat to 550°C, keep it warm for 4 hours, then wash the reaction product three times with water and pickle three times, wherein the pickling pH=2 (hydrochloric acid), pickling for 60 minutes each time, wash the pickled product with deionized water After reaching neutrality, high-purity metal chromium is obtained, and the chemical elements of high-purity metal chromium powder are detected, and the results are shown in Table 2.

Embodiment 2

[0032] Purify anhydrous chromium chloride by sublimation under dry chlorine gas; weigh 38g of superior pure KCl and 22g of anhydrous LiCl respectively, heat to 400°C to make mixed molten salt, then successively mix 9g of purified anhydrous chromium chloride and Add 2.45g of 99.99% magnesium metal (120% of the theoretical amount) into the molten salt and react for 4 hours. The whole reaction process is protected by dry argon, and then the reaction product is washed with water and pickled three times in sequence, wherein the pickling pH=3 (hydrochloric acid), pickled 100 minutes, the pickling product was washed to neutrality with deionized water to obtain high-purity metal chromium, and the chemical elements of high-purity metal chromium powder were detected, and the results are as shown in table 2.

Embodiment 3

[0034] Anhydrous chromium chloride was sublimated and purified under nitrogen protection; 40g of anhydrous NaCl was weighed, heated to 850°C to make molten salt, and then 9g of purified anhydrous chromium chloride and 2.45g of high-purity metal magnesium (theoretical 120% of the amount) was added molten salt to react for 2h, and the whole reaction process was protected by argon, and then the reaction product was washed with water 3 times and pickled 3 times successively, wherein the pickling pH=2 (hydrochloric acid), pickled for 30 minutes, and the The pickling product was washed with deionized water until neutral to obtain high-purity metal chromium. The chemical elements of the high-purity metal chromium powder were detected, and the results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com