Carrier brightener precursor and carrier brightener for alkaline zinc-plating or zinc alloy electroplating solution and electroplating solution

A technology of carrier brightener and electroplating solution, applied in the field of carrier brightener, electroplating solution, and carrier brightener precursor, can solve the problems of easy "foaming" of the coating, low cathode current efficiency, good dispersion ability of the carrier brightener, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

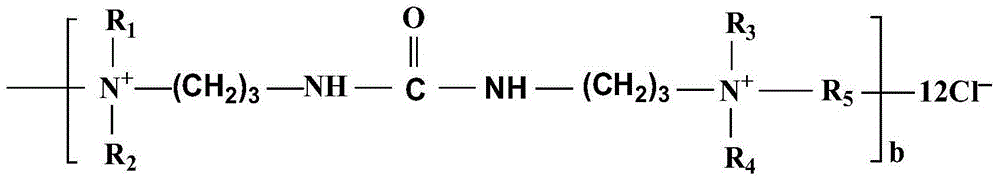

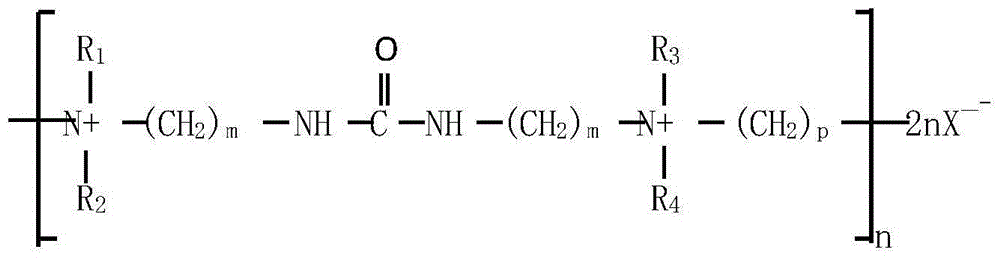

[0091] Example 1 Carrier Brightener Precursor Mixed Amine Used in Alkaline Zinc Plating or Zinc Alloy Electroplating Bath and Preparation Method thereof

[0092] The urea or urea calculated according to the reaction formula and the urea homologue (N-methylurea or N-phenylurea) of the general structural formula (four), and the compound (3- Dimethylaminopropylamine or 2-dimethylaminoethylamine) into a three-necked flask equipped with stirring, condensing and reflux, temperature measuring (controlling) devices and heating devices, and the end of the reflux condenser should be connected to an ammonia absorption device (use 10% dilute sulfuric acid as absorbent). Replace the air in the system with nitrogen. The temperature was raised while stirring, and when the temperature rose to 110°C, the mixture became homogeneous, and a small amount of ammonia gas began to evolve. As the temperature rises, the release rate of ammonia gas will increase. Control it at the rate of temperature ...

Embodiment 2

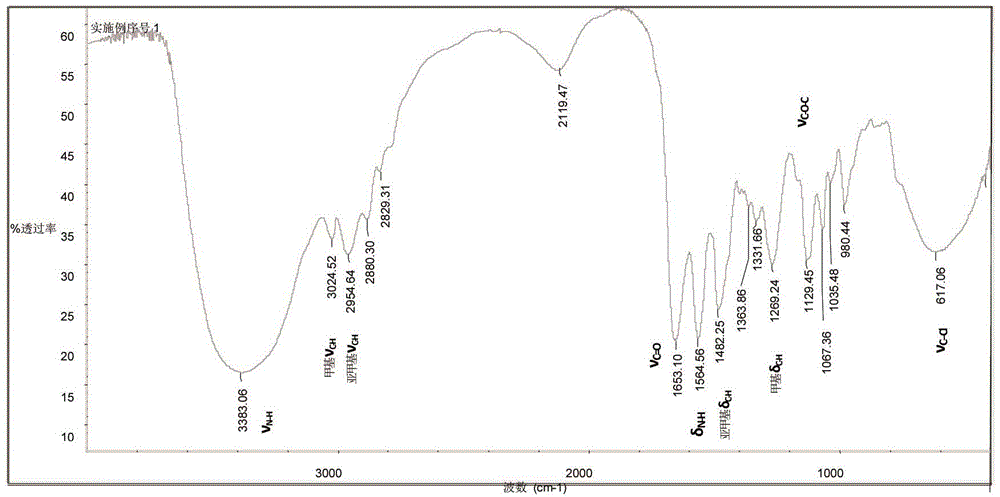

[0095] Embodiment 2 is used for the carrier brightener in alkaline galvanizing or zinc alloy electroplating solution and preparation method thereof

[0096] Add a known amount of precursor mixed amines into the three-necked flask. Prepare and measure pure water. The amount of pure water added is 100-105% of the total amount of other substances participating in the reaction, so that the solid content of the carrier brightener in the obtained product is 45%. Dissolve the calculated amount of sodium hydroxide in the prepared pure water, then add it into the three-necked flask, and dissolve it with the mixed amine while stirring. The reaction device should be equipped with a stirring, condensing and reflux device, a temperature measuring (controlling) device, a heating device and a separatory funnel for feeding. Add the calculated linking agent into the separating funnel, heat up while stirring, and add the linking agent dropwise from the separating funnel to the reactant when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com