Monocrystal silicon inverted pyramid array structure suede, and preparation method and application thereof

An inverted pyramid and array structure technology, which is applied in the field of monocrystalline silicon inverted pyramid array structure suede and its preparation, can solve the problems of inability to adapt to large-scale industrial production, complex processing process, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] Preparation method of monocrystalline silicon inverted pyramid array structure textured surface

[0070] The invention also provides a method for preparing the suede with the inverted pyramid array structure of the single crystal silicon of the invention. Typically, this method includes:

[0071] (1) generating a polymer microsphere monolayer film on at least one main surface of the substrate to obtain a substrate-polymer microsphere monolayer film;

[0072] (2) generating a mask layer on the substrate-polymer microsphere monolayer film to obtain a substrate-polymer microsphere monolayer film-mask layer;

[0073] (3) removing the polymer microspheres in the substrate-polymer microsphere monolayer film-mask layer, so that the main surface exposes a plurality of units not covered by the mask;

[0074] (4) The units not covered by the mask are etched into inverted pyramid-shaped embossed grooves, and an inverted pyramid array structure texture is obtained on the main sur...

Embodiment 1

[0094] Monocrystalline Silicon Inverted Pyramid Array Structure Texture No.1

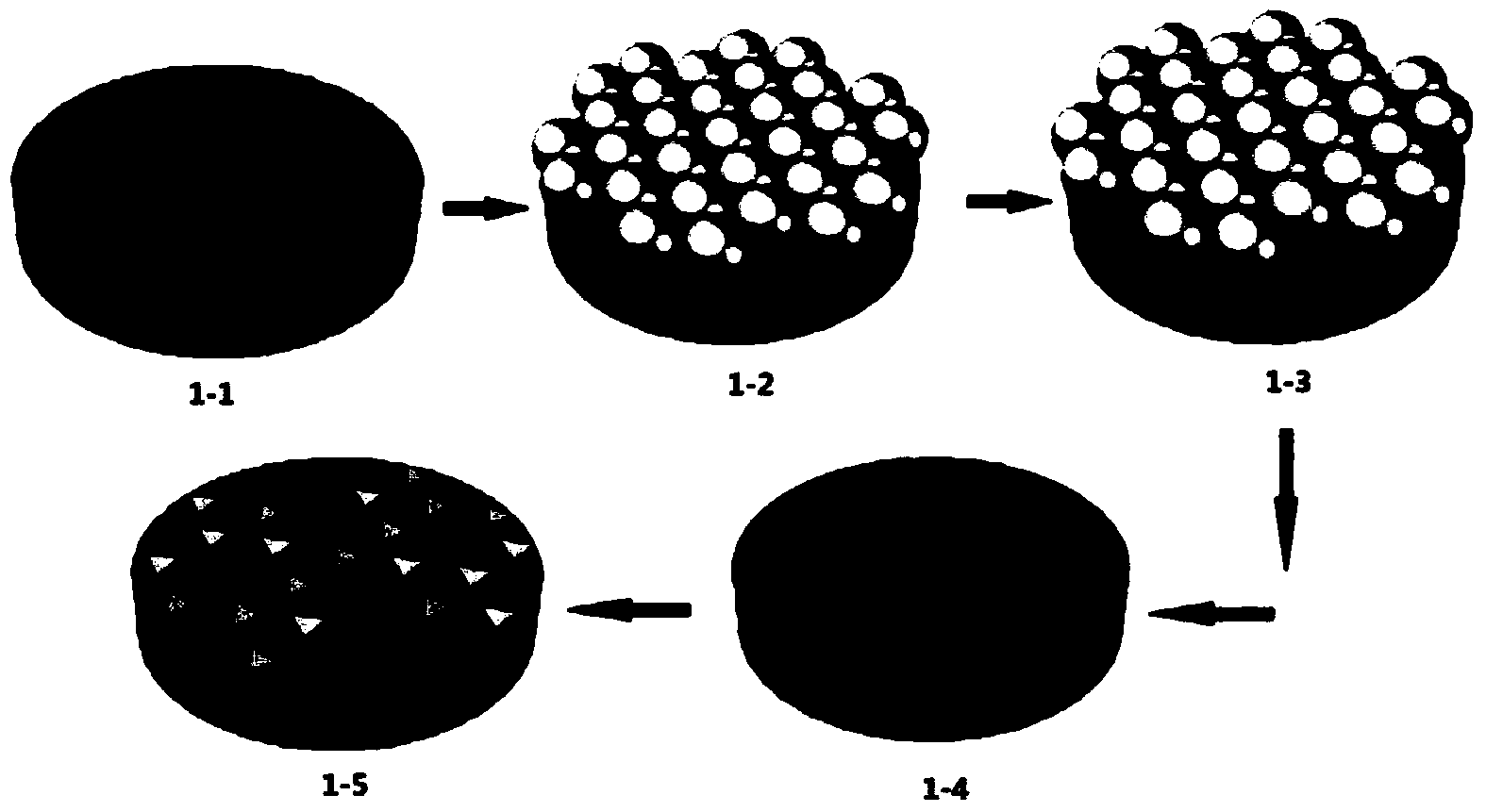

[0095] Such as figure 1 As mentioned, the method for preparing the monocrystalline silicon inverted pyramid structure suede in this embodiment comprises the following steps:

[0096] The silicon substrate is cleaned and ready for use, such as Picture 1-1 shown;

[0097] The drift method in self-assembly is used to form the array of polymer nanospheres, and then paved on the substrate, where the average diameter of the polymer microspheres can be selected between 50nm and 10000nm, such as Figure 1-2 shown;

[0098] Using PECVD (Plasma Enhanced Chemical Vapor Deposition, plasma enhanced chemical vapor deposition method) in Figure 1-2 A silicon nitride mask layer is grown on the surface of the object shown to protect the surface of the silicon substrate, and the thickness of the silicon nitride film is controllable, such as Figure 1-3 shown;

[0099] pyrolysis Figure 1-3 The polymer balls o...

Embodiment 2

[0104] Monocrystalline Silicon Inverted Pyramid Array Structure Texture No.2

[0105] Such as figure 1 As mentioned, the method for preparing the monocrystalline silicon inverted pyramid structure suede in this embodiment comprises the following steps:

[0106] The silicon substrate is cleaned and ready for use, such as Picture 1-1 shown;

[0107] The drift method in self-assembly is used to form the array of polymer nanospheres, and then paved on the substrate, where the average diameter of the polymer microspheres can be selected between 50nm and 10000nm, such as Figure 1-2 shown;

[0108] Using the DC sputtering method in Figure 1-2 A metal Ti mask layer is grown on the surface of the shown object to protect the surface of the silicon substrate, and the thickness of the Ti film is controllable, such as Figure 1-3 shown;

[0109] Removal by sonication with toluene solution Figure 1-3 The polymer balls on the medium-silicon substrate are then wet-etched with lye t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com