An ultrathin film based on nano-au-enhanced Raman spectroscopy and its application in dye detection

A Raman spectroscopy, ultra-thin film technology, applied in the ultra-thin film and its application in dye detection, can solve the problems of difficult to accurately control the manufacturing process, low substrate SERS activity, poor regeneration, and poor stability, and achieve adsorption. -Desorption process, improved sensitivity, high orientation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

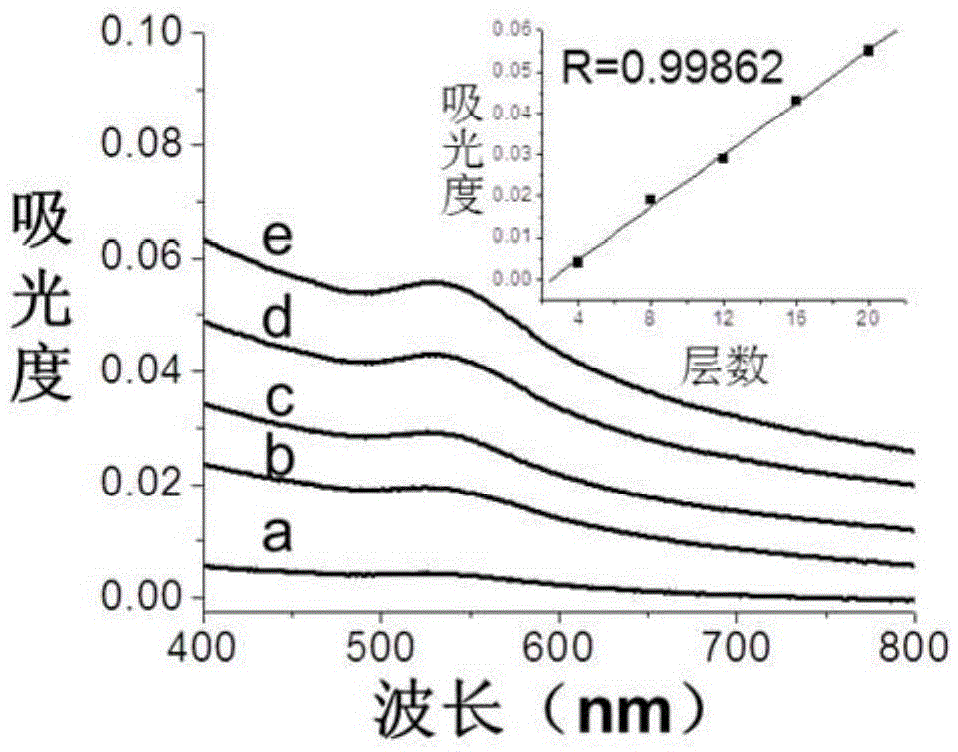

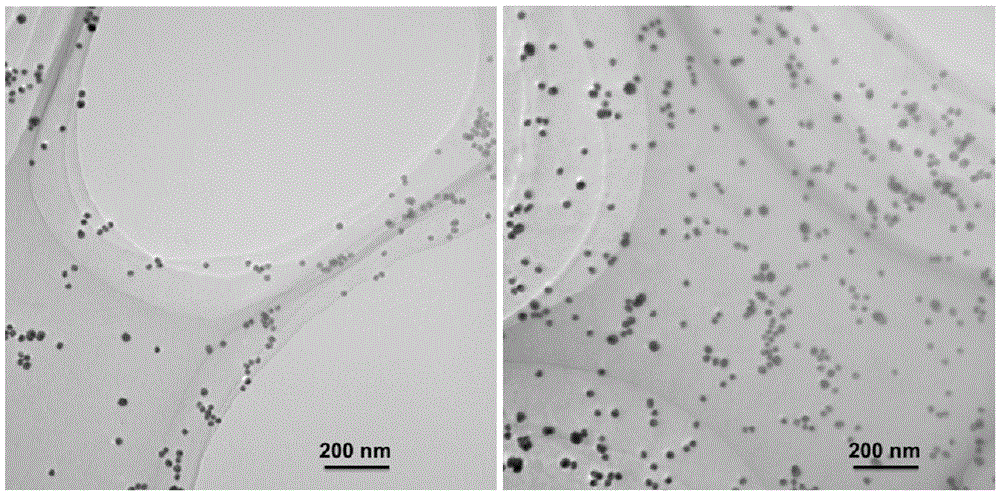

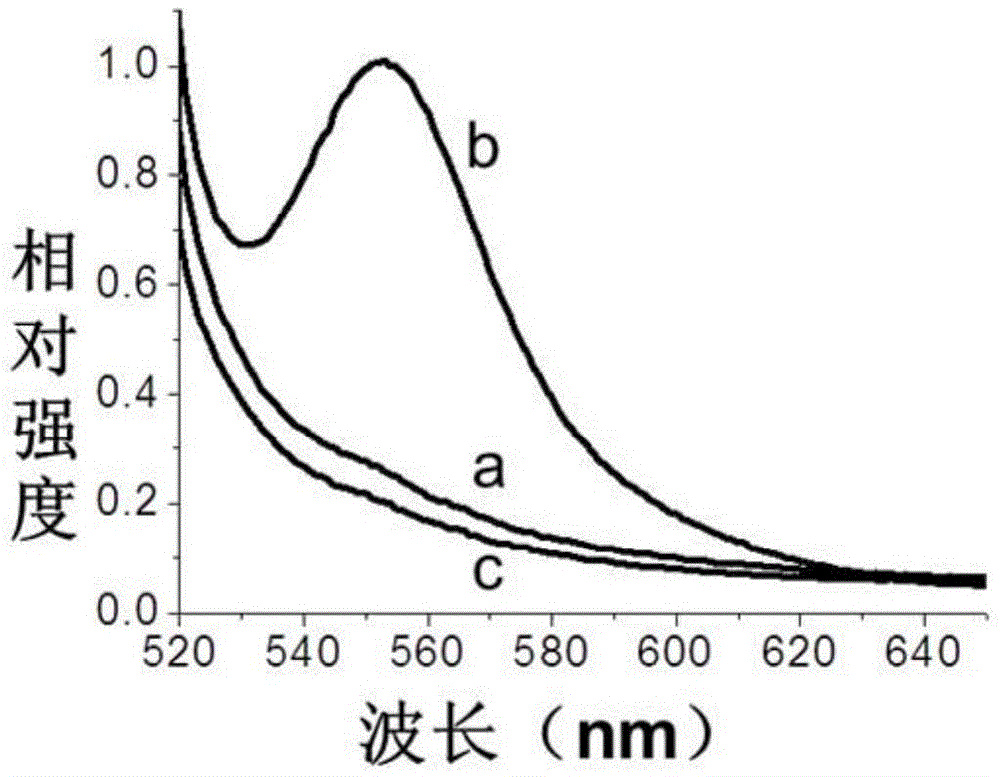

[0031] The preparation of step A. hydrotalcite nanosheet colloidal solution: take by weighing 0.513gMg(NO 3 ) 2 ·6H 2 O, 0.375gAl(NO 3 ) 3 9H 2 O (Mg / Al=2) and 0.721g urea were dissolved in 70ml of deionized water, ultrasonically stirred to make it evenly mixed, then poured into a high-pressure reactor and reacted at 100°C for 24h, taken out, washed with deionized water, and dried to obtain carbonate plugs. layer magnesium aluminum hydrotalcite; after grinding 0.3g carbonate intercalated magnesium aluminum hydrotalcite with 0.5mol NaNO 3 and 1.5 mmol concentrated HNO 3 Mix and add to 300ml boiled deionized water, in N 2 Stirred under protection for 36h, used to remove CO 2 Centrifugal washing with deionized water for 4 times, drying, and grinding to obtain nitrate-intercalated magnesium-aluminum hydrotalcite; 0.1g of nitrate-intercalated magnesium-aluminum hydrotalcite is added in 100ml formamide, and the 2 Stir for 48h under protection, then centrifuge, discard the prec...

Embodiment 2

[0041] The preparation of step A. hydrotalcite nanosheet colloidal solution: take by weighing 0.513gMg(NO 3 ) 2 ·6H 2 O, 0.375gAl(NO 3 ) 3 9H 2 O (Mg / Al=2) and 0.721g urea were dissolved in 60ml of deionized water, ultrasonically stirred to make it evenly mixed, then poured into a high-pressure reactor and reacted at 110°C for 24h, taken out, washed with deionized water, and dried to obtain carbonate plugs. layer magnesium aluminum hydrotalcite; after grinding 0.25g carbonate intercalated magnesium aluminum hydrotalcite with 0.4mol NaNO 3 and 1.2 mmol concentrated HNO 3 Mix and add to 300ml boiled deionized water, in N 2 Stirred under protection for 36h, used to remove CO 2 Centrifugal washing with deionized water for 4 times, drying, and grinding to obtain nitrate-intercalated magnesium-aluminum hydrotalcite; 0.08g of nitrate-intercalated magnesium-aluminum hydrotalcite is added in 100ml formamide, and the 2 Stir for 48h under protection, then centrifuge, discard the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com