Preparation method for full beam milk ice cream

A production method and ice cream technology, which are applied in the fields of frozen desserts, food science, and applications, can solve the problem of not accepting soy milk, etc., and achieve the effects of delicate taste, smooth taste and complete shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

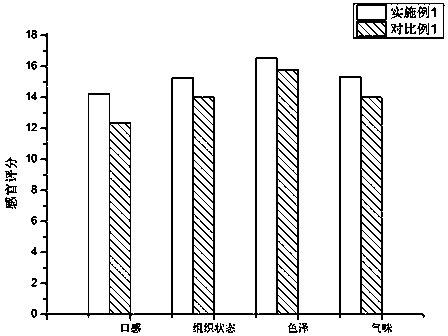

Embodiment 1

[0029] A method for making high-quality whole soybean milk ice cream, the amount of raw materials is as follows (1000g): whole soybean milk 350g; whole milk powder 70g; anhydrous butter 50g; white sugar 140g; monoglyceride 1.5g; guar gum 3g; Water 385.5g.

[0030] (1) Soymilk preparation: first screen the soybeans to obtain 50g of soybean raw materials with bright color, uniform grain size, plumpness, and no insects and rats. Soak at room temperature for 12 hours, wash off the soaking liquid with running water, add water according to the soybean water ratio of 1:6 (g / g), heat to 90°C, and then coarsely grind (beater, model: JYL-C090, manufacturer: Joyoung Co., Ltd. Ltd).

[0031] (2) Deodorization treatment of soybean milk: when the temperature of coarsely ground soybean milk drops to 45°C, add 0.5% aldol dehydrogenase based on the mass of soybean milk, and perform ultra-high pressure treatment at 250 MPa for 6 minutes (ultra-high pressure food processing device, Model: UHPF...

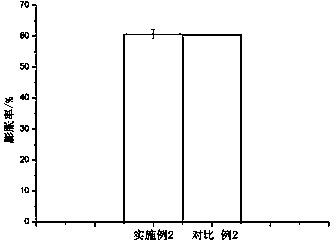

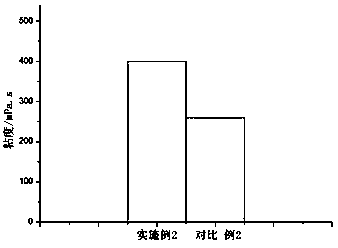

Embodiment 2

[0040] A method for making high-quality whole soybean milk ice cream, the amount of raw materials is as follows (1000g): 250g whole soybean milk; 80g skimmed milk powder; 60g coconut oil; 100g white sugar; 20g maltose; 2g sucrose ester; 3g xanthan gum; 30g eggs ; Water 455g.

[0041] (1) Soymilk preparation: first screen the soybeans to obtain 25g of soybean raw materials with bright color, uniform grain size, plumpness, and no insects and rats. Soak at room temperature for 12 hours, wash off the soaking liquid with running water, add water according to the soybean water ratio of 1:9 (g / g), heat to 90°C, and then coarsely grind (beater, model: JYL-C090, manufacturer: Joyoung Co., Ltd. Ltd).

[0042] (2) Deodorization treatment of soybean milk: When the temperature of coarsely ground soybean milk drops to 48°C, add 0.4% aldol dehydrogenase based on the mass of soybean milk, and perform ultra-high pressure treatment at 200 MPa for 5 minutes (ultra-high pressure food processing ...

Embodiment 3

[0051] A method for making high-quality whole soybean milk ice cream, the amount of raw materials is as follows (1000g): 270g whole soybean milk; 80g skimmed milk powder; 60g coconut oil; 120g white sugar; 2g sucrose ester; 3g xanthan gum; 30g egg; 435g water .

[0052] (1) Soymilk preparation: first screen the soybeans to obtain 30g of soybean raw materials with bright color, uniform grain size, plumpness, and no insects and rats. Soak at room temperature for 10 hours, wash off the soaking liquid with running water, add water according to the soybean water ratio of 1:8 (g / g), heat to 90°C, and then coarsely grind (beater, model: JYL-C090, manufacturer: Joyoung Co., Ltd. Ltd).

[0053] (2) Deodorization treatment of soybean milk: When the temperature of coarsely ground soybean milk drops to 50°C, add 0.4% aldol dehydrogenase based on the mass of soybean milk, and perform ultra-high pressure treatment at 220MPa for 4 minutes (ultra-high pressure food processing device, model: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com