Applied composite solvent decoloring and revivifying method

A composite solvent and new method technology, applied in the direction of immiscible liquid separation, etc., can solve problems such as difficult removal, light transmittance decrease, pigment deepening, etc., to achieve the effect of reducing production and operation costs, reducing process burden, and enhancing decolorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

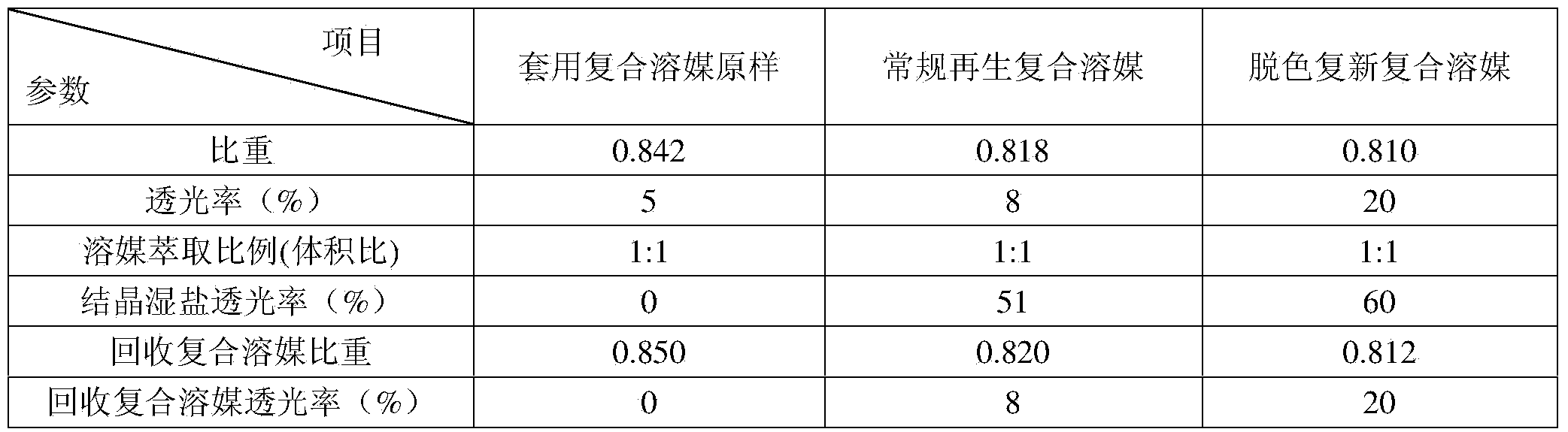

Embodiment 1

[0031] In the present invention, in the production process of sulfur red veterinary medicine, the applied composite solvent used for alkaline extraction and refining of acetone mother liquor with solvent is used as the experimental material. The applied composite solvent has heavy residual pigment and impurities, and the conventional method is not ideal for treatment, but after the treatment of the present invention Compared with the conventional method, it has a strong experimental contrast.

[0032] (1) Add purified water with a volume ratio of 1:0.1 to the applied compound solvent, adjust the pH value of the aqueous phase of the system to 2.0-3.0 with concentrated hydrochloric acid, and stir evenly at a slow speed;

[0033] (2) Stirring finishes, above-mentioned mixed solution is left standstill phase separation, reclaims waste acid;

[0034] (3) Take the composite solvent after pickling and add a sodium hypochlorite solution with a volume ratio of 1:1 and a concentration o...

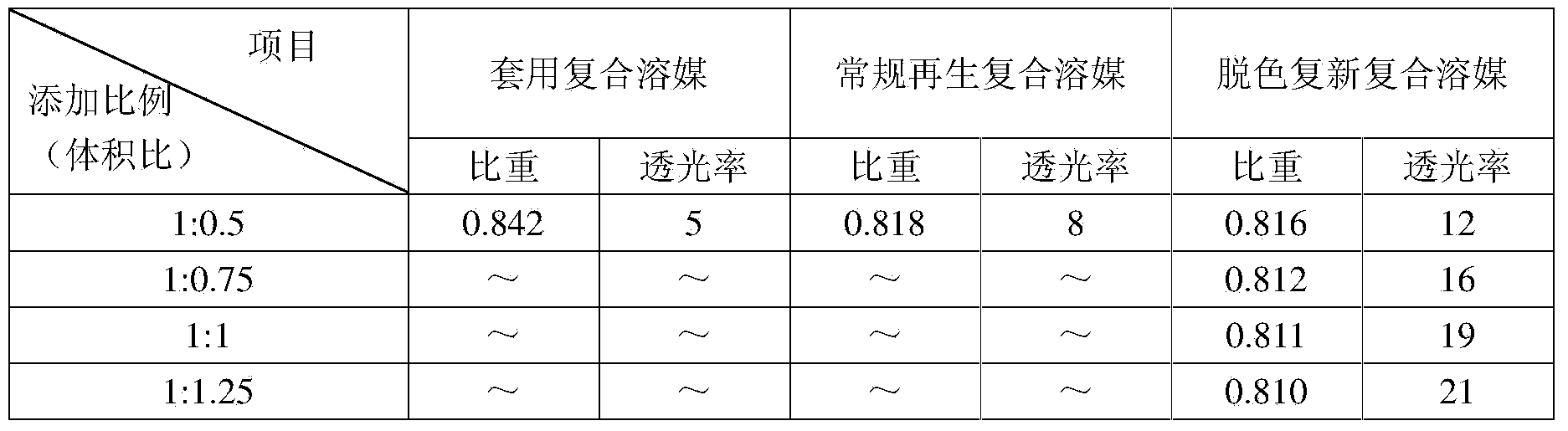

Embodiment 2

[0049] (1) Add purified water with a volume ratio of 1:0.1 to the applied compound solvent, adjust the pH value of the aqueous phase of the system to 2.0-3.0 with concentrated hydrochloric acid, and stir evenly at a slow speed;

[0050] (2) Stirring finishes, above-mentioned mixed solution is left standstill phase separation, reclaims waste acid;

[0051] (3) Take the composite solvent after pickling and add a sodium hypochlorite solution with a volume ratio of 1:0.5 to 1.25 and a concentration of 10% and stir slowly for 30 minutes;

[0052] (4) After stirring, the above-mentioned decolorizing solution is left to separate phases, and the decolorizing agent solution is reclaimed;

[0053] (5) Get the decolorized composite solvent and add the saturated sodium chloride solution with a volume ratio of 1:0.2 and stir evenly;

[0054] (6) Adjust the pH value of the aqueous phase of the system to 8.0 with dilute hydrochloric acid, and stir slowly for 30 minutes;

[0055] (7) Stirri...

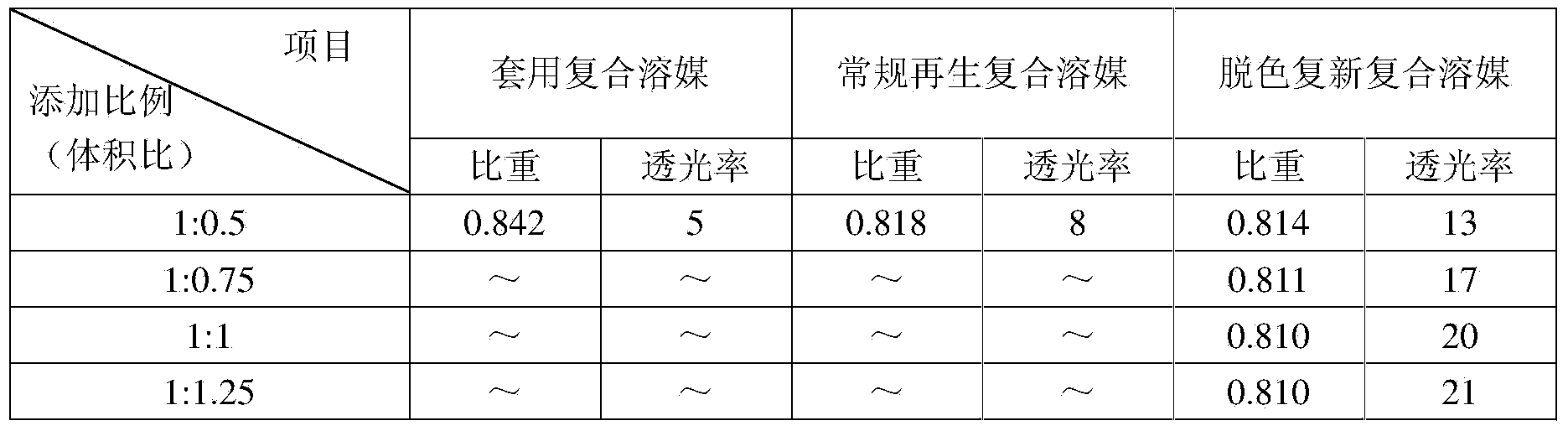

Embodiment 3

[0061] (1) Add purified water with a volume ratio of 1:0.1 to the mechanically applied composite solvent, adjust the pH value of the aqueous phase of the system to 2.0~3.0 with concentrated hydrochloric acid, and stir evenly at a slow speed;

[0062] (2) stirring finishes, the above-mentioned mixed solution is left standstill for phase separation, and waste acid is recovered;

[0063] (3) take the composite solvent after pickling and add the sodium hypochlorite solution whose volume ratio is 1:0.5~1.25, the concentration is 80%, and stir slowly for 30min;

[0064] (4) stirring finishes, the above-mentioned decolorizing solution is left standstill for phase separation, and the decolorizing agent solution is recovered;

[0065] (5) get the composite solvent after decolorization and add the saturated sodium chloride solution of its volume ratio 1:0.2 and stir;

[0066] (6) adjust the pH value of the aqueous phase of the system to 8.0 with dilute hydrochloric acid, and stir at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com