Method for quickly synthesizing zeolite molecular sieve by microwave solid-phase method

A zeolite molecular sieve, a technology for synthesizing zeolite, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, crystalline aluminosilicate zeolite, etc., can solve the problem of long gel ageing time, unfavorable industrial production, and long synthesis period, etc. problems, to achieve excellent adsorption and exchange performance, avoid high pressure hazards, and simplify the operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Rapid synthesis of FAU zeolite molecular sieves by microwave solid-phase method

[0034] 3.7g sodium silicate nonahydrate, 0.34g pseudo-boehmite, 0.28g ammonium chloride solid were mixed, and after grinding for 5 minutes with a mortar, put into a bottle stopper with a hole (for safety considerations, the system kept constant Press, use a bottle stopper with a hole), microwave in a household microwave oven for 50 minutes, filter after cooling, wash with water until nearly neutral, and dry at 60°C to obtain a nano FAU zeolite molecular sieve product.

[0035] The molar ratio of the reaction mixture is Na 2 O: SiO 2 :Al 2 o 3 :H 2 O: NH 4 + =2.55:4.2:1:37.7:1.65.

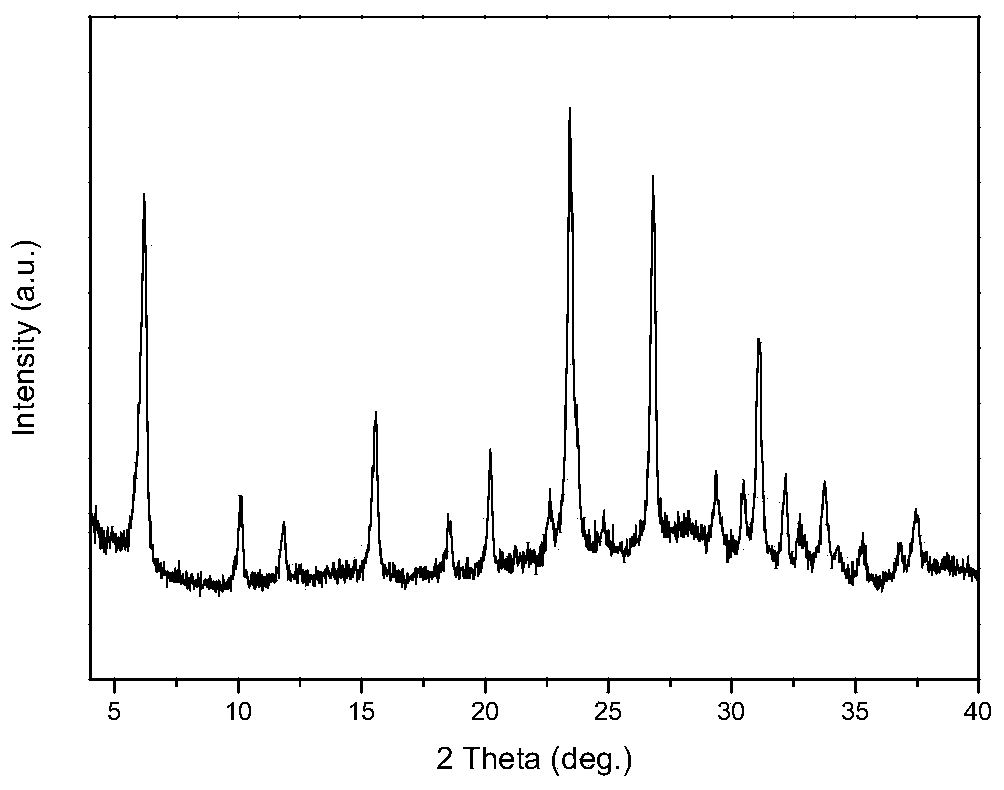

[0036] attached figure 1 , 2 are XRD and SEM figure of embodiment 1 sample respectively. The product was analyzed by X-ray powder diffraction to be FAU type zeolite molecular sieve. The crystal grain size is about 300-600nm analyzed by scanning electron microscope.

Embodiment 2

[0037] Example 2: Rapid synthesis of FAU zeolite molecular sieves by microwave solid-phase method

[0038]Mix 3.23g sodium silicate nonahydrate, 0.34g pseudo-boehmite, and 0.2g ammonium chloride solid raw materials, grind them with a mortar for 5 minutes, put them into a reaction bottle with a stopper with a hole, and put them in a household microwave oven. Medium microwave for 50 minutes, filter after cooling, wash with water until nearly neutral, and dry at 60°C to obtain nano FAU type zeolite molecular sieve products.

[0039] The molar ratio of the reaction mixture is Na 2 O: SiO 2 :Al 2 o 3 :H 2 O: NH 4 + =2.5:3.7:1:33.5:1.2.

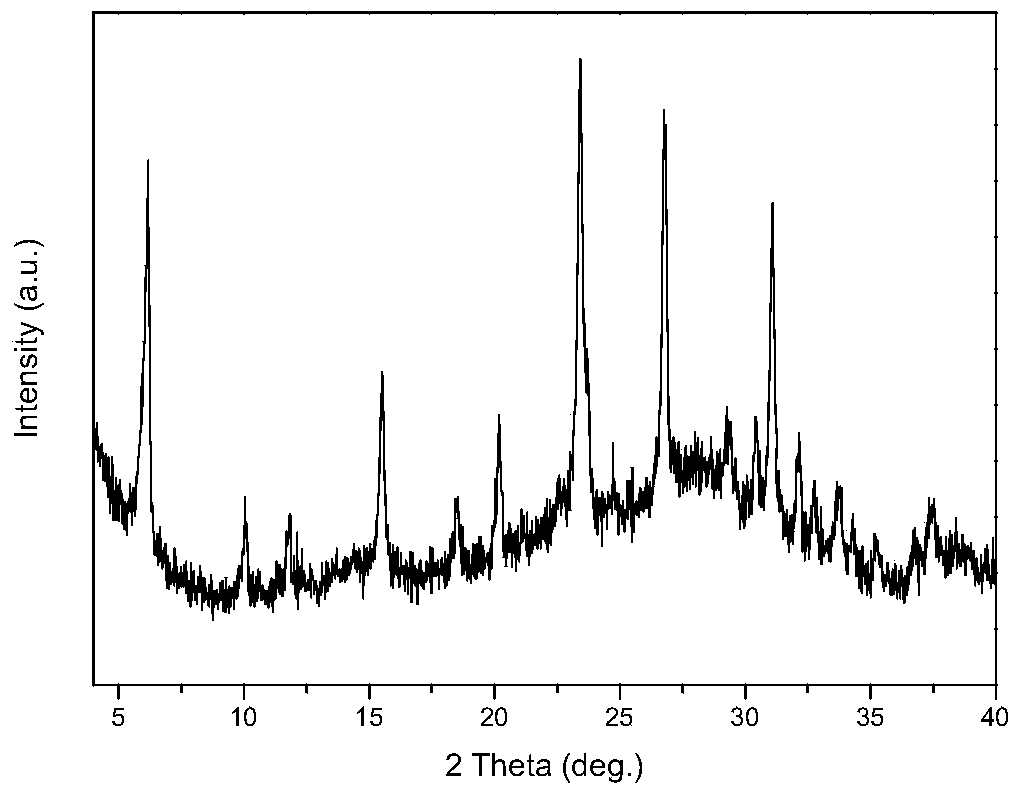

[0040] attached image 3 , 4 are XRD and SEM figure of embodiment 2 samples respectively. The product was analyzed by X-ray powder diffraction to be FAU zeolite molecular sieve. The crystal grain size is about 300-600nm analyzed by scanning electron microscope.

Embodiment 3

[0041] Example 3: Rapid synthesis of FAU zeolite molecular sieves by microwave solid-phase method

[0042] Mix 3.25g of sodium silicate nonahydrate, 0.34g of pseudo-boehmite, 0.1g of ammonium acetate and 0.2g of potassium chloride as solid raw materials, grind them with a mortar for 10 minutes, and put them into a reaction bottle with a hole in the stopper Microwave in a household microwave oven for 50 minutes, filter after cooling, wash with water until nearly neutral, and dry at 60°C to obtain a nanometer FAU zeolite molecular sieve product.

[0043] The molar ratio of the reaction mixture is Na 2 O: SiO 2 :Al 2 o 3 :H 2 O: NH 4 + :K + =3.3:3.7:1:33.5:0.42:0.86. The product was analyzed by X-ray powder diffraction to be FAU zeolite molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com