Preparation method for novel ultrahigh-performance concrete pile casing used in pile foundation project

An ultra-high-performance concrete technology, applied in the field of bridge construction, can solve problems such as curling or local deformation, increase in construction costs, and affect the quality of holes, so as to improve structural toughness, solve easy curling, and be conducive to environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

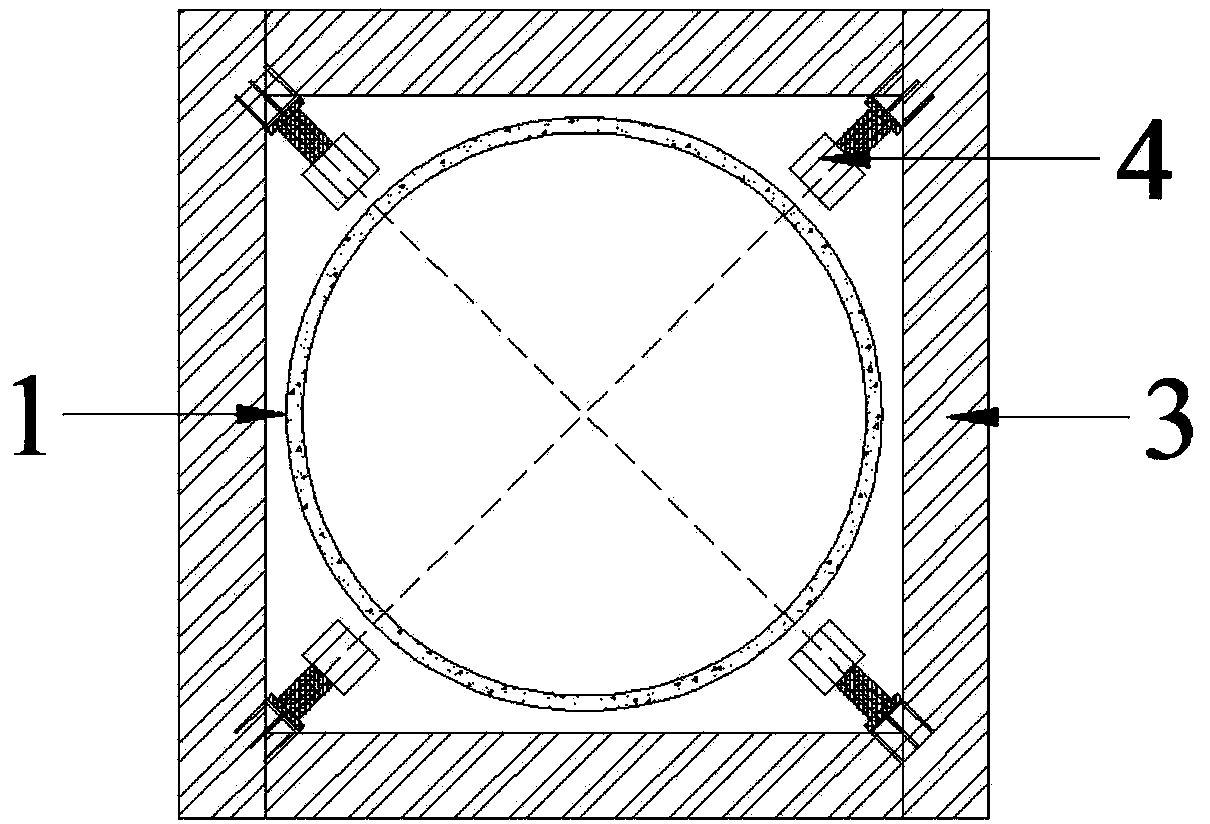

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

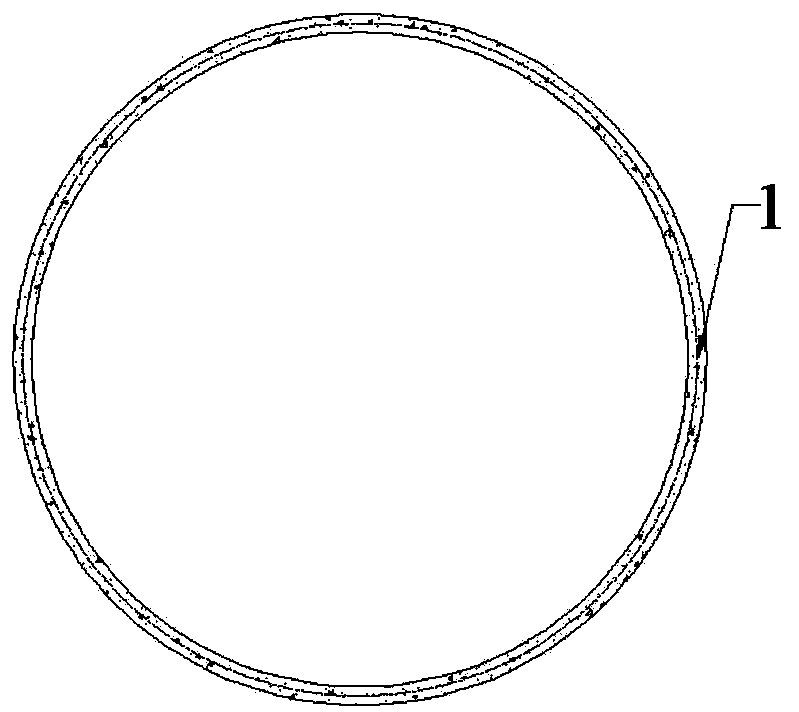

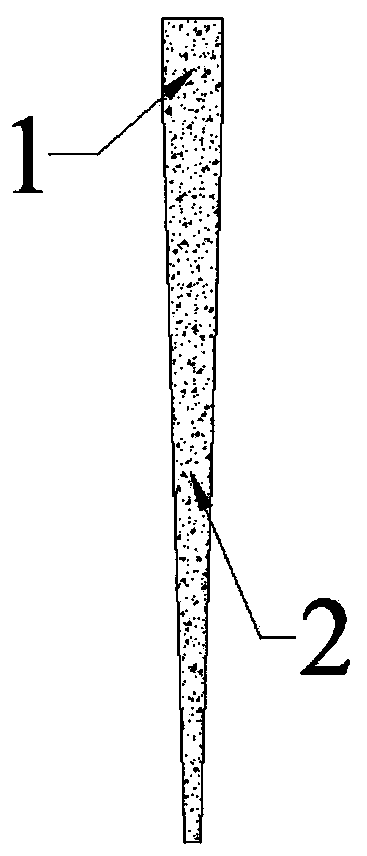

[0022] A method for preparing a novel ultra-high-performance concrete casing used in pile foundation engineering. The casing is made of ultra-high-performance concrete, and the production ratio of the ultra-high-performance concrete is:

[0023] Cement: fine sand: finely ground quartz sand powder: silica fume powder: water reducing agent: water = 100: 400-470: 80-120: 10-50: 0.6-1.0: 37-45, and the preparation temperature is 15°C-35 ℃; the cement used is P.O.42.5 Portland cement; the fine sand modulus used is ≤1, the mud content is ≤1.5%, the mud content is ≤0.5%, and the chloride content is ≤0.02%; the finely ground quartz sand used Silica content > 99.99%, ferric oxide < 0.001%, Mohs hardness is 7; the water reducer used is polycarboxylate water reducer; ultra-fine steel fibers are added in the preparation process of ultra-high perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com