Water-based acrylic resin

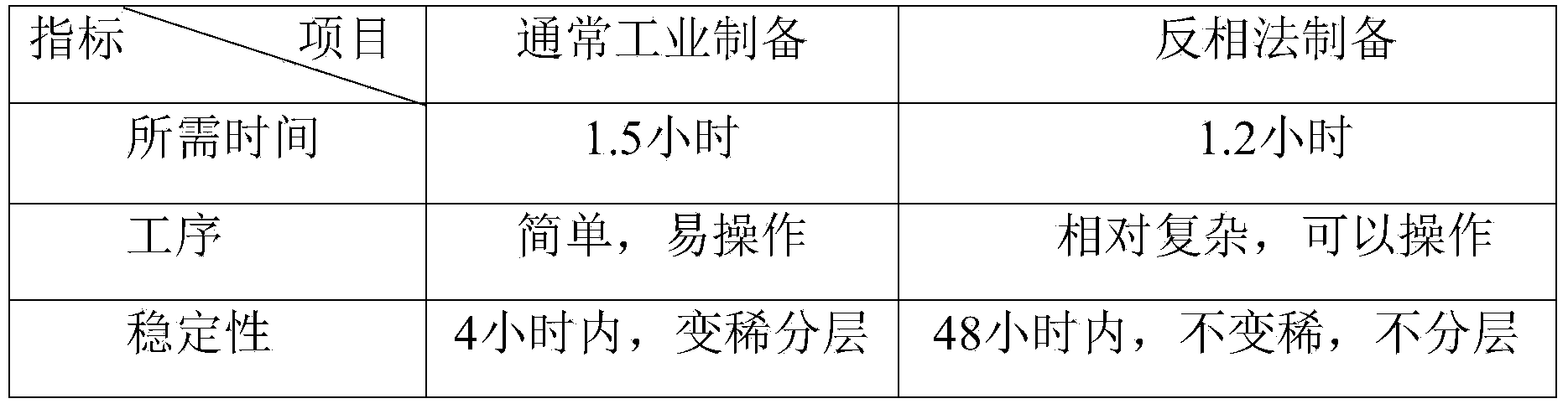

A water-based acrylic acid and butyl acrylate technology, which is applied in the chemical industry, can solve the problems of poor stability of acrylic resin emulsion and long dissolution time, and achieve the effects of shortening the preparation time, reducing the amount of use, and forming a thick film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

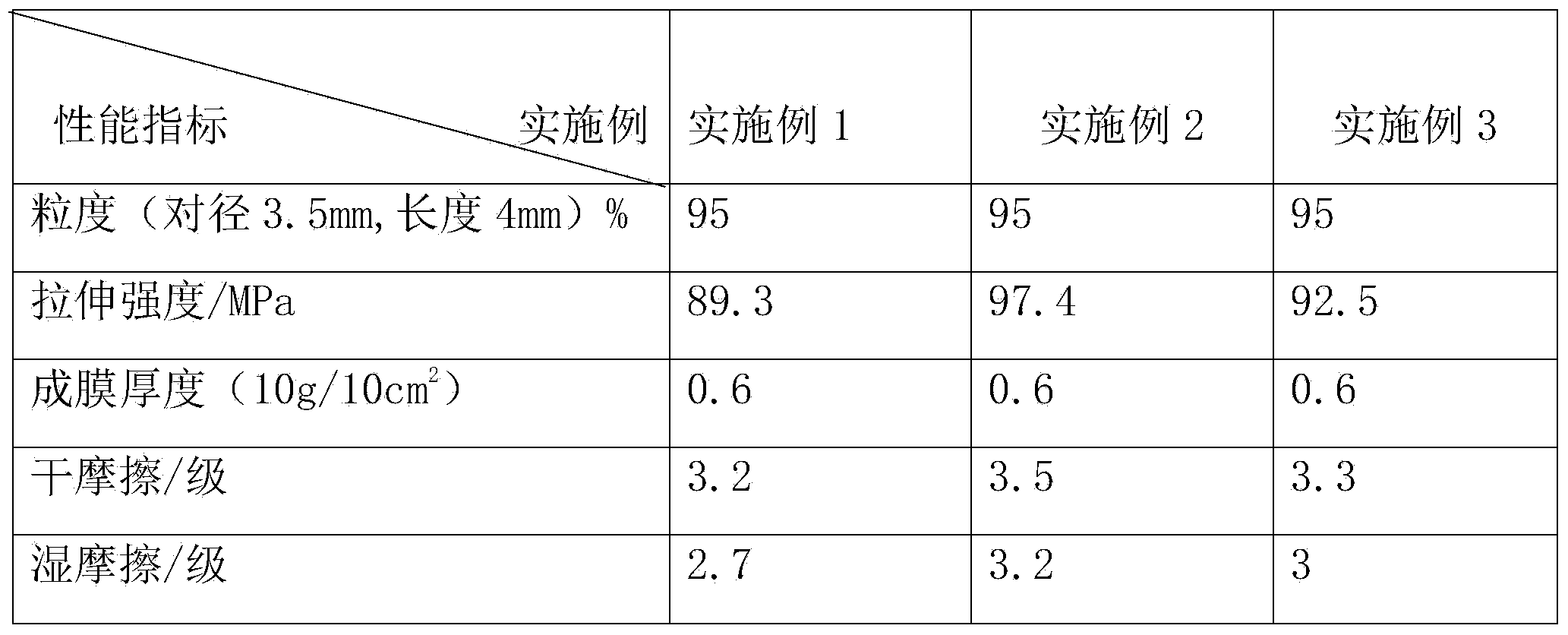

Examples

Embodiment 1

[0021] Take the following chemical raw materials: 300g of ethyl acrylate, 100g of butyl acrylate, 40g of methyl methacrylate, 10g of methacrylic acid, 10g of hydroxyethyl methacrylate, 4g of diacetone acrylamide, 1g of oxalyl hydrazide, 10g of triethanolamine , potassium persulfate 2g, butyl palmitate 15g, surfactant 20g, defoamer 0.5g, preservative 0.1g and water medium 400g.

[0022] Among the above components, the surfactant contains a mixed reagent whose mass fraction is 33% DNS-360 reagent and 67% polyoxyethylene sorbitan fatty acid ester T-40 reagent; the defoamer is modified by Defom5300 A defoamer for polysiloxane; the preservative is LANXESS P-91 reagent, and the active ingredient is a mixture of bromonitropropylene glycol and various isothiazolinones.

[0023] Concretely prepare the method for aqueous acrylic resin, may further comprise the steps:

[0024] 1) Preparation of pre-emulsion: Add ethyl acrylate, butyl acrylate, methyl methacrylate, hydroxyethyl methacryl...

Embodiment 2

[0029] Take the following chemical raw materials: 320g of ethyl acrylate, 120g of butyl acrylate, 50g of methyl methacrylate, 10g of methacrylic acid, 10g of hydroxyethyl methacrylate, 10g of diacetone acrylamide, 3g of oxalyl hydrazide, 10g of triethanolamine , Potassium persulfate 2g, butyl palmitate 15g, surfactant 30g, defoamer 0.5g, preservative 0.1g water medium 450g.

[0030] Among the above components, the surfactant contains a mixed reagent whose mass fraction is 33% DNS-360 reagent and 67% polyoxyethylene sorbitan fatty acid ester T-40 reagent; the defoamer is modified by Defom5300 A defoamer for polysiloxane; the preservative is LANXESS P-91 reagent, and the active ingredient is a mixture of bromonitropropylene glycol and various isothiazolinones.

[0031] Concretely prepare the method for aqueous acrylic resin, may further comprise the steps:

[0032] 1) Preparation of pre-emulsion: Add ethyl acrylate, butyl acrylate, methyl methacrylate, hydroxyethyl methacrylate...

Embodiment 3

[0037] Take the following chemical raw materials: 310g ethyl acrylate, 110g butyl acrylate, 45g methyl methacrylate, 10g methacrylic acid, 10g hydroxyethyl methacrylate, 6g diacetone acrylamide, 2g oxalyl hydrazide, 10g triethanolamine , potassium persulfate 2g, butyl palmitate 15g, surfactant 25g, defoamer 0.5g, preservative 0.1g water medium 420g.

[0038]Among the above components, the surfactant contains a mixed reagent whose mass fraction is 33% DNS-360 reagent and 67% polyoxyethylene sorbitan fatty acid ester T-40 reagent; the defoamer is modified by Defom5300 A defoamer for polysiloxane; the preservative is LANXESS P-91 reagent, and the active ingredient is a mixture of bromonitropropylene glycol and various isothiazolinones.

[0039] Concretely prepare the method for aqueous acrylic resin, may further comprise the steps:

[0040] 1) Preparation of pre-emulsion: Add ethyl acrylate, butyl acrylate, methyl methacrylate, hydroxyethyl methacrylate, methacrylic acid, diacet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com