Hyperbranched polyester urethane acrylate ultraviolet-cured coating and preparation method thereof

A technology of urethane acrylate and hyperbranched polyester, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem of not fully satisfying the physical and chemical properties of coatings, and achieve the effects of excellent physical and chemical properties, high flexibility and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

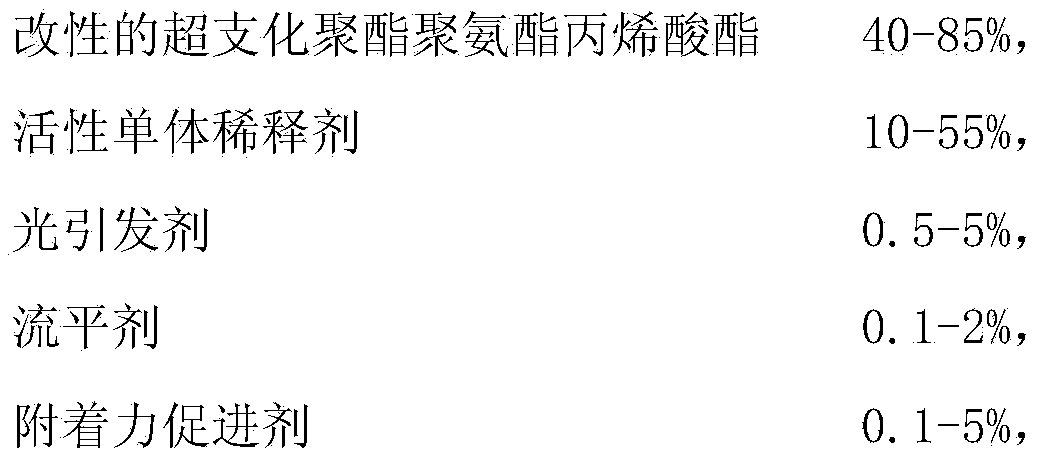

Method used

Image

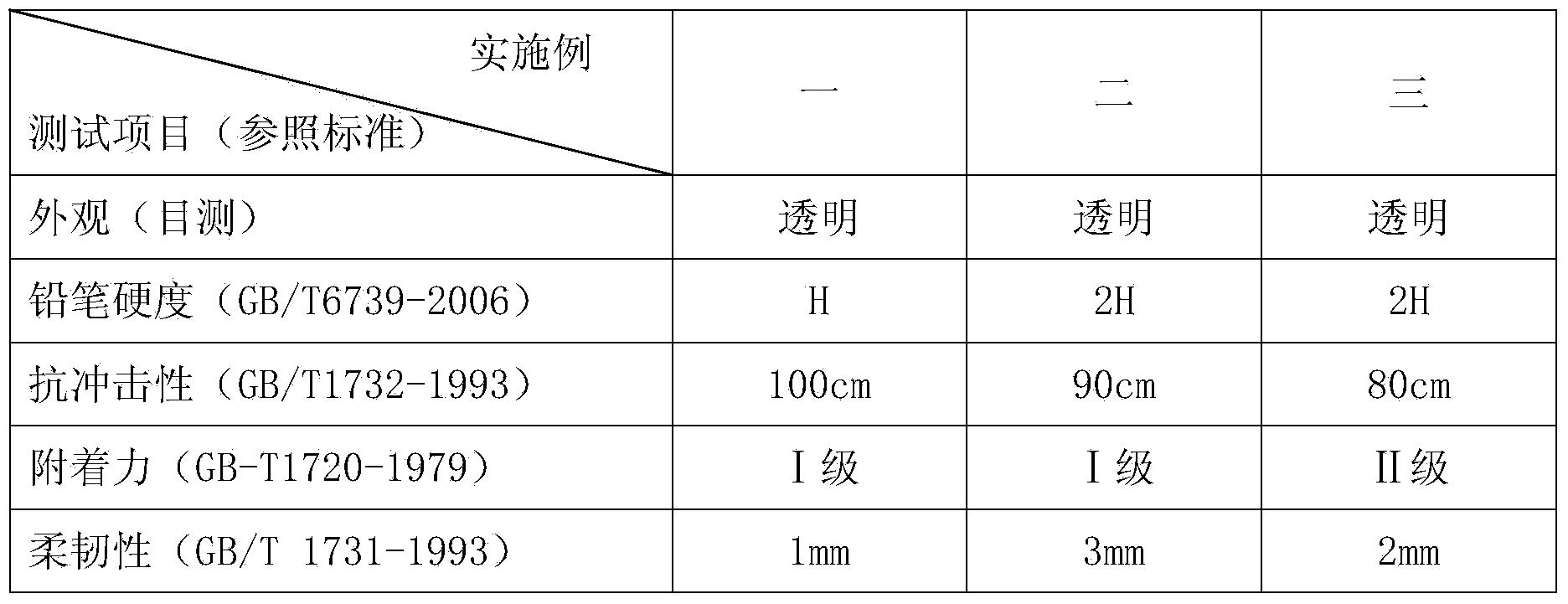

Examples

Embodiment 1

[0034] Step 1, the preparation of hyperbranched polyester

[0035] Add 13.4kg of trimethylolpropane and 0.4kg of p-toluenesulfonic acid to the reaction kettle equipped with a stirring device, a temperature control system, and nitrogen gas inlet and outlet pipes, raise the temperature to 70°C, and add 120.6kg of them in batches after melting Dimethylolpropionic acid, under the conditions of stirring and nitrogen gas to remove water, raise the reaction temperature of the system to 140 ° C, stop nitrogen gas after 6 hours of reaction, vacuumize, continue to react for 2 hours and then stop to prepare hyperbranched polyester .

[0036] Step 2, the preparation of the hyperbranched polyester modified by long-chain acid

[0037] Add the hyperbranched polyester that 118kg step 1 makes in the reactor that stirrer, temperature control system, nitrogen import and outlet pipe are housed, then slowly add 101.7kg oleic acid and 0.6kg p-toluenesulfonic acid mixed solution, be warming up to ...

Embodiment 2

[0046] Step 1, the preparation of hyperbranched polyester

[0047] Add 13.4kg of trimethylolpropane and 0.4kg of p-toluenesulfonic acid to the reaction kettle equipped with a stirring device, a temperature control system, and nitrogen gas inlet and outlet pipes, raise the temperature to 70°C, and add 40.2kg of them in batches after melting Dimethylol propionic acid, under the conditions of stirring and nitrogen gas to remove water, raise the reaction temperature of the system to 120 ° C, stop nitrogen gas after 9 hours of reaction, vacuumize, continue to react for 3 hours and then stop to prepare hyperbranched polyester .

[0048] Step 2, the preparation of the hyperbranched polyester modified by long-chain acid

[0049] Add the hyperbranched polyester that 51kg step one makes in the reactor that stirrer, temperature control system, nitrogen gas import and export pipe are housed, then slowly add 22kg undecylenic acid and 0.2kg p-toluenesulfonic acid to it and mix liquid, hea...

Embodiment 3

[0058] Step 1, the preparation of hyperbranched polyester

[0059] Add 13.4kg of trimethylolpropane and 1.1kg of p-toluenesulfonic acid to the reaction kettle equipped with a stirring device, a temperature control system, and nitrogen gas inlet and outlet pipes, raise the temperature to 70°C, and add 361.8kg in batches after melting Dimethylolpropionic acid, under the condition of stirring and nitrogen gas to remove water, raise the reaction temperature of the system to 160 ° C, stop nitrogen gas after 4 hours of reaction, vacuumize, continue to react for 1 hour and then stop to prepare hyperbranched polyester .

[0060] Step 2, the preparation of the hyperbranched polyester modified by long-chain acid

[0061] Add the hyperbranched polyester that 337kg step 1 makes in the reactor that stirrer, temperature control system, nitrogen import and outlet pipe are housed, then slowly add 273kg oleic acid and 1.8kg p-toluenesulfonic acid mixed solution to it, heat up To 190° C., rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com