Preparation method of potassium sodium niobate knn single crystal

A technology of potassium sodium niobate and single crystal, which is applied in the field of piezoelectric materials and can solve the problems of small size of potassium sodium niobate KNN single crystal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] After drying potassium carbonate, sodium carbonate and niobium oxide with a purity of 99.99% at 300°C for 2 hours, batching potassium carbonate 112.51g, sodium carbonate 36.98g, niobium oxide 309.16g according to the ratio of 0.7:0.3:1, after ball milling for 20 hours and mixing uniformly Heat treatment at 850°C for 3 hours in a covered platinum crucible to obtain K 0.7 Na 0.3 NbO 3 Polycrystalline. Then the resulting K 0.7 Na 0.3 NbO 3 Polycrystalline ball milled for 20 hours, sieved, based on K 0.7 Na 0.3 NbO 3 Add a certain proportion of potassium carbonate and sodium carbonate as flux to the total amount of polycrystalline, K 2 CO 3 :Na 2 CO 3 : K 0.7 Na 0.3 NbO 3 The molar ratio is equal to 21:9:200 by adding K 2 CO 3 33.75g, Na 2 CO 3 11.10 g, placed again in a covered platinum crucible for heat treatment at 850°C for 3 hours. The resultant was pulverized with a corundum mortar, finely ground for 1 hour, sieved, put into a platinum growth crucib...

example 2

[0042] Example 2, the purity is 99.99% potassium carbonate, sodium carbonate, niobium oxide 300 ℃ dried for 2 hours according to the ratio of 0.5: 0.5: 1 batching, potassium carbonate 80.37g, sodium carbonate 61.64g, niobium oxide 309.16g, ball mill 15 After mixing evenly for 1 hour, place it in a covered platinum crucible and heat-treat at 850°C for 5 hours to obtain K 0.5 Na 0.5 NbO 3 Polycrystalline. Then the resulting K 0.5 Na 0.5 NbO 3 The polycrystalline material is crushed and ground in a corundum mortar for about 1 hour, and sieved, based on K 0.5 Na 0.5 NbO 3 A certain proportion of potassium carbonate and sodium carbonate are added to the total amount of polycrystalline powder as a flux, K 2 CO 3 :Na 2 CO 3 : K 0.5 Na 0.5 NbO 3 The molar ratio is equal to 15:15:200 by adding K 2 CO 3 24.11g, Na 2 CO 3 18.49g, ball milled for 20 hours, mixed evenly and put into the platinum growth crucible until it was full, and then the growth crucible was placed in...

example 3

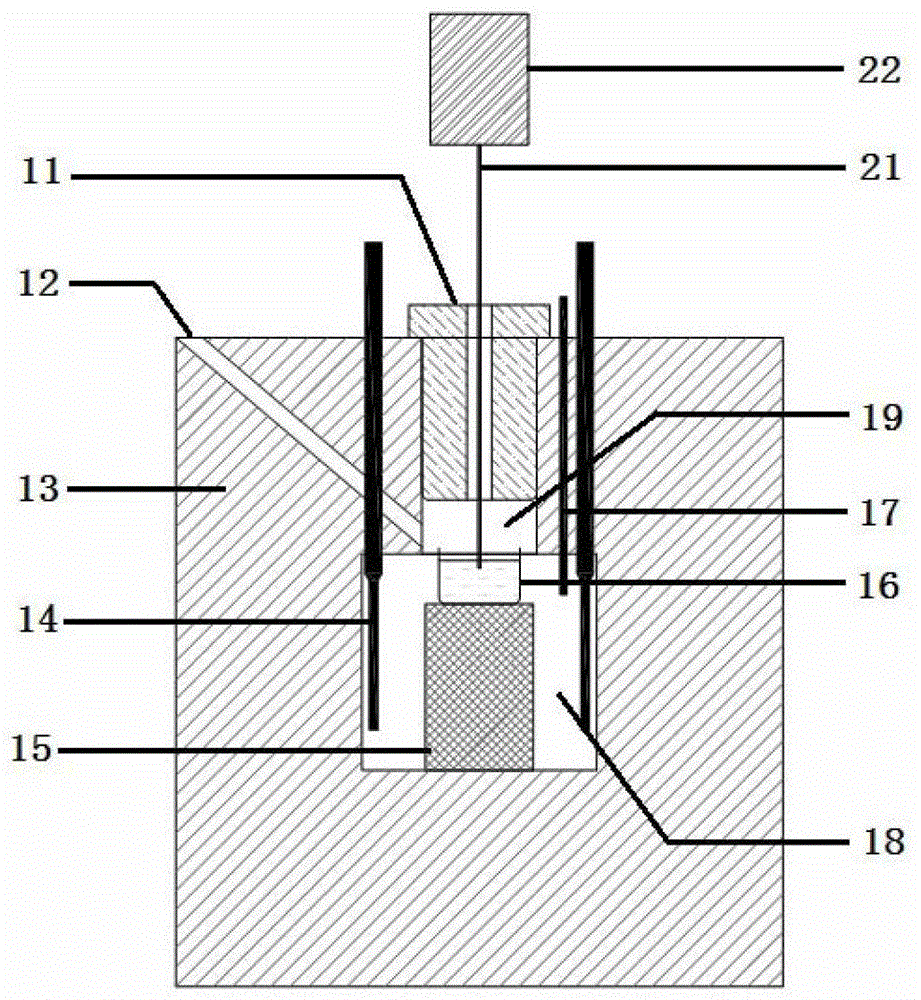

[0044] Example 3, being 99.99% salt of wormwood, sodium carbonate, niobium oxide 300 ℃ of drying 2 hours according to the ratio batching of 0.85: 0.15: 1 after the purity is 99.99%, salt of wormwood 136.62g, sodium carbonate 18.49g, niobium oxide 309.16g, add A certain proportion of potassium carbonate and sodium carbonate as flux, K 2 CO 3 :Na 2 CO 3 : The molar ratio of generalized KNN powder is equal to 17:3:200 by adding K 2 CO 3 27.32g, Na 2 CO 3 3.70g, ball milled for 20 hours, mixed evenly, cold isostatic pressed into blocks, placed in a covered platinum crucible and heat treated at 850°C for 10 hours. The resultant was pulverized in a corundum mortar and finely ground for 1 hour, then placed in a platinum growth crucible, and then the growth crucible was placed in a crystal growth furnace, such as figure 1 For the device shown, the temperature gradient above the liquid level is 15°C / cm. After heating up to 1090°C to completely melt the raw materials, it was fou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com