Smoke and wind simulation heat exchange device

A technology of heat exchange device and flue gas, which is applied in the testing of measuring devices, instruments, machines/structural components, etc., can solve problems such as dust blocking or corrosion of dust collectors, influence on production and operation, and heat transfer of fluids that are not easy to solid particles and impurities. Achieve the effects of reducing the impact of corrosion, reducing equipment loss, and shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

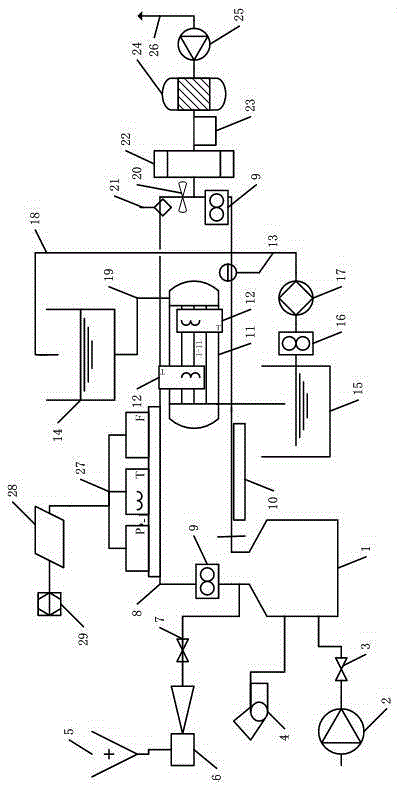

[0012] like figure 1 As shown, the flue gas simulation heat exchange device of the present invention includes a coal-fired boiler 1, a blower 2, an air volume control valve 3, a coal feeder 4, an ash hopper 5, a screw feeder 6, an ash volume control valve 7, and a flue 8 , flue gas flowmeter 9, heat exchanger 11, wall temperature detector 12, flue gas analyzer 13, upper water tank 14, lower water tank 15, water flow meter 16, water pump 17, upper water pipe 18, down pipe 19, anemometer 20. Acid dew point detector 21, dust removal device 22, collection device 23, desulfurization device 24, induced draft fan 25, air duct 26, sensor group 27, data acquisition card 28, and host computer 29. The water pump 17 is a frequency conversion water pump, the flue gas flowmeter 9 is an intelligent vortex flowmeter 9, and the sensor group 27 is composed of a temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com