High performance liquid chromatographic analysis method for pyromellitic dianhydride

A technology of pyromellitic dianhydride and high performance liquid chromatography, which is applied in the field of analysis, can solve the problems of difficult testing, cumbersome process, and high boiling point, and achieve simple sample processing and analysis procedures, good chromatographic peak shape, and reproducible good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Prepare 1L mobile phase: Accurately weigh 1g of tetramethylammonium bisulfate and dissolve it in 100mL of acetonitrile. After ultrasonic oscillation for 1-10min, add 600mL of n-hexane and 300mL of tetrahydrofuran in sequence, ultrasonically oscillate for 30-60min to mix evenly, and use 0.45 Filter through a μm membrane for later use.

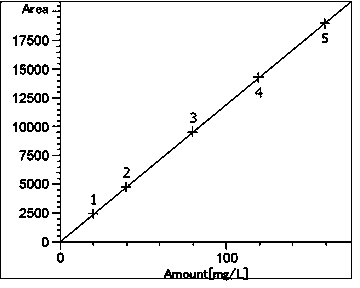

[0041] 2. Prepare PMDA standard solutions with concentrations of 20 mg / L, 40 mg / L, 80 mg / L, 120 mg / L and 160 mg / L: Accurately weigh 25-2000 mg of PMDA standard product to the nearest 0.1 mg, and place In a 50mL volumetric flask, dilute to the mark with the above-mentioned mobile phase, mix evenly by ultrasonication for 5min, seal and cool and let stand, when the liquid in the volumetric flask returns to the scale line, accurately pipette 2mL of the solution into a 50mL volumetric flask, and use The mobile phase was diluted to the mark, mixed by ultrasonication for 5 minutes, and then filtered with a 0.45 μm filter membrane.

[0042] 3...

Embodiment 2

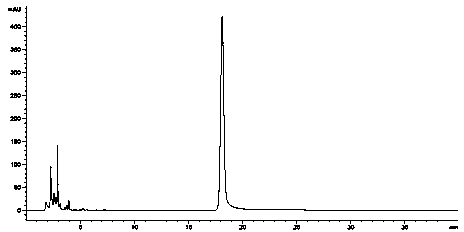

[0049] Based on the standard curve in Example 1, PMDA sample A solution was prepared and analyzed. Accurately weigh PMDA sample A 1000mg, preparation method, chromatographic conditions and integral calculation method are with embodiment 1 thereafter. The spectrum is attached Figure 4 As shown, the purity of the sample was 99.80%.

Embodiment 3

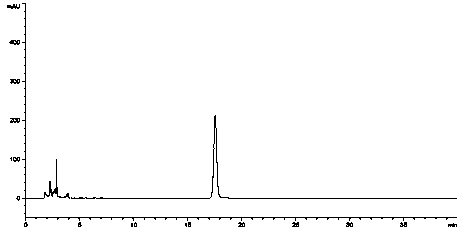

[0051] Based on the standard curve in Example 1, PMDA sample B solution was prepared and analyzed. Accurately weigh the PMDA sample B 1000mg, and then the preparation method, chromatographic conditions and integral calculation method are the same as in Example 1. The spectrum is attached Figure 5As shown, the purity of the sample was 95.73%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com