Synthesis method of nano magnetic hydroxyl iron oxide ozone catalyst with core-shell structure

A technology of iron oxyhydroxide and nano-magnetic technology, applied in the direction of iron oxide/iron hydroxide, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve secondary pollution, iron oxyhydroxide catalyst Difficult to recycle, difficult to apply and other problems, to achieve the effect of increasing the production rate and quantity, simple preparation, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

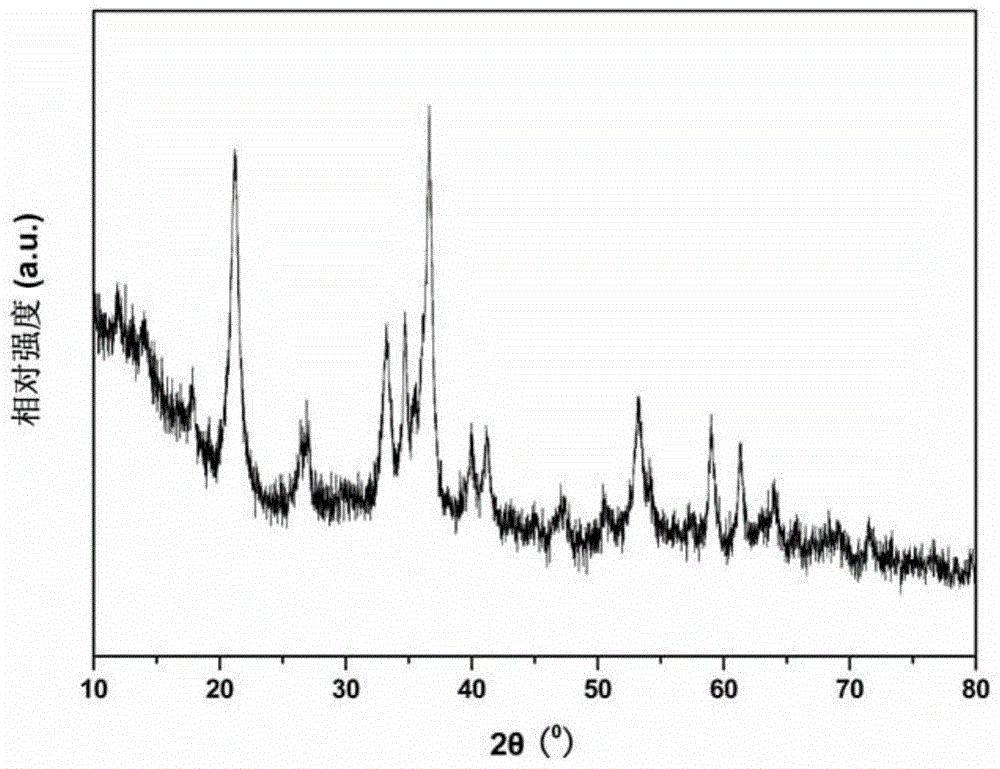

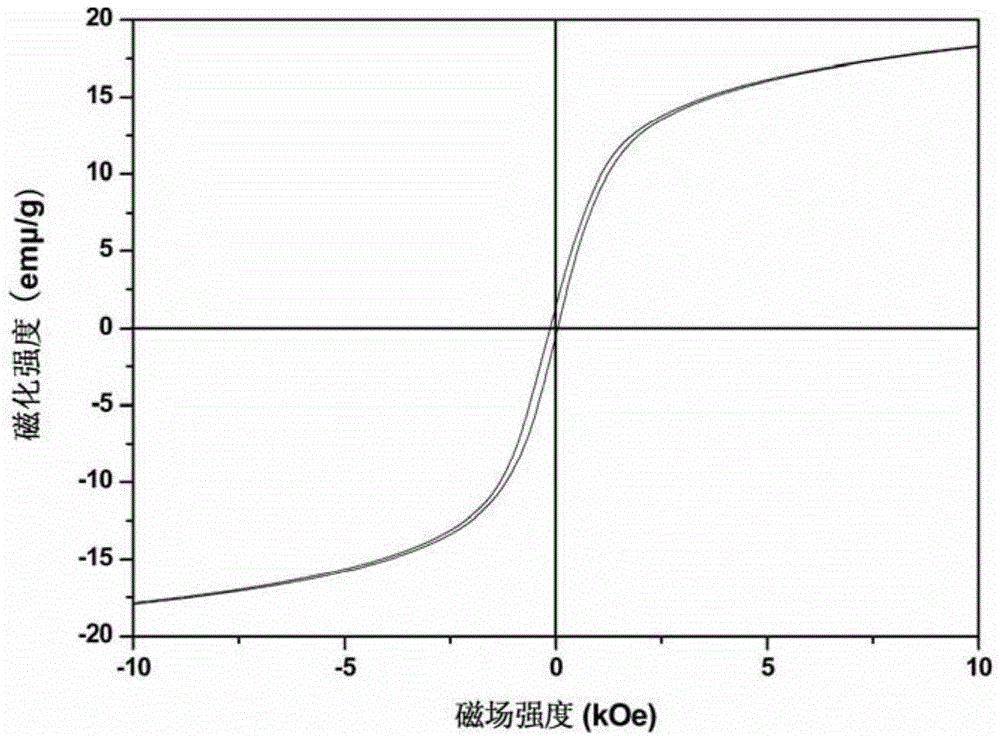

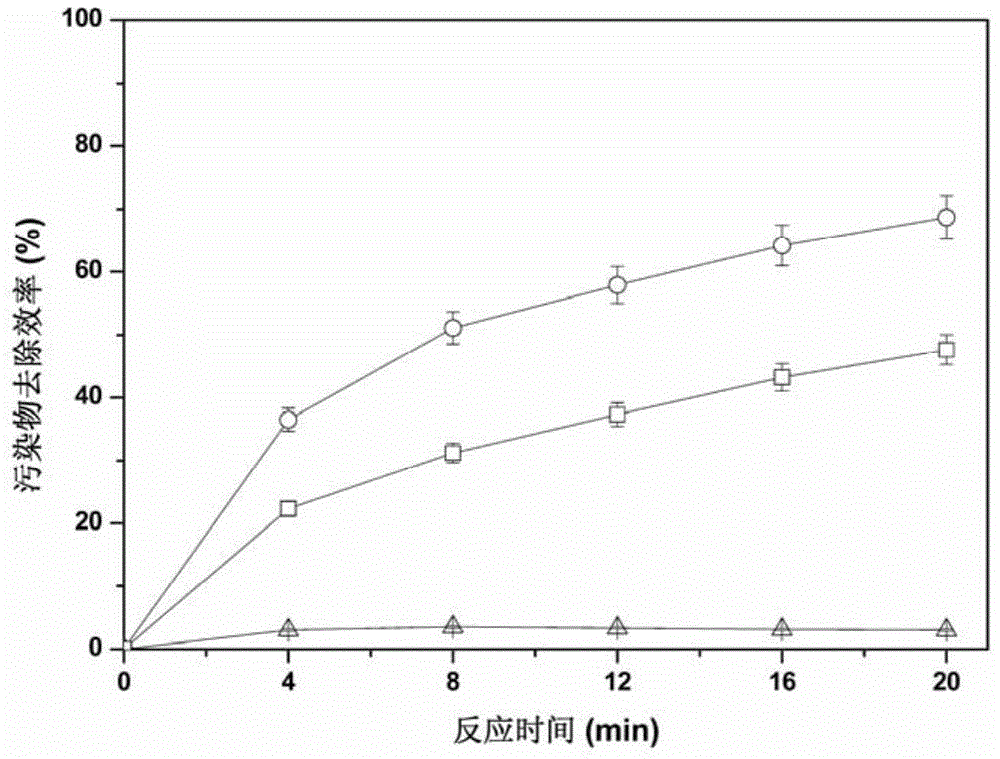

[0017] Specific embodiment one: the synthesis method of the core-shell structure nano-magnetic iron oxyhydroxide ozone catalyst of this embodiment is carried out according to the following steps:

[0018] 1. Prepare an iron salt solution with an iron ion molar concentration of 0.5mol / L to 2mol / L, and then add additives to make the molar concentration of the additives 0.01mol / L to 0.03mol / L to obtain a mixed solution A;

[0019] 2. Under the condition that the temperature is 20°C to 30°C, titrate the mixed solution A obtained in step 1 with an alkali solution with a molar concentration of 0.5mol / L to 2mol / L until the pH value of the mixed solution A is 9 to 12, and obtain Suspension, after standing for 10min to 30min, activated at 40°C to 80°C for 6h to 12h under nitrogen protection, then ultrasonically dispersed for 10min to 20min, and then added tetrachloride with a molar concentration of 0.1mol / L to 0.5mol / L Ethoxysilane, magnetically stirred at a speed of 120r / min to 300r / m...

specific Embodiment approach 2

[0024] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the iron salt solution described in step one is a ferrous salt solution or a mixed solution of a ferrous salt and a ferric salt, wherein the ferrous The molar ratio of ferrous ions to ferric ions in the mixed solution of salt and ferric salt is 1: (2-3.5). Others are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Specific embodiment three: this embodiment is different from specific embodiment one or two in that: the ferrous salt is ferrous chloride or ferrous sulfate, and the ferric salt is ferric nitrate, ferric sulfate or ferric chloride . Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com