Preparation method of PE (Poly Ethylene)/EVA (Ethylene Vinyl Acetate) composite fabric

A composite fabric and material selection technology, which is applied in the field of preparation of PE and EVA composite fabrics, can solve the problems of uneven color, fading, and instability of the fabric, and achieve the effect of uniform and stable color and delay fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

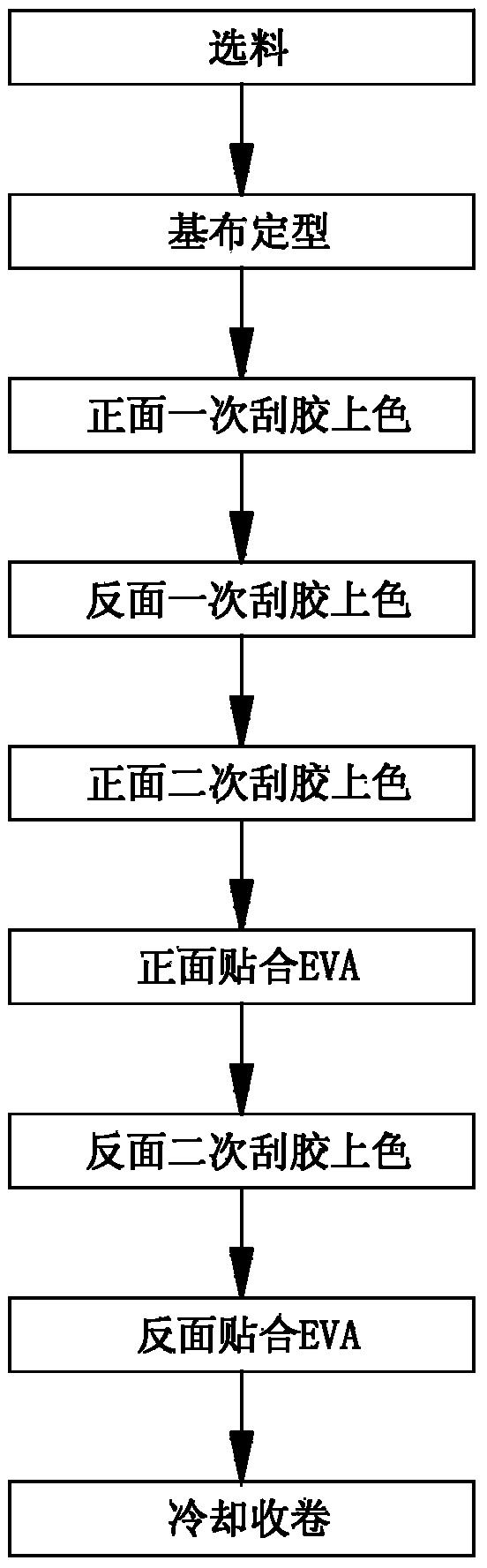

Image

Examples

Embodiment 1

[0025] In the present embodiment, a preparation method of PE and EVA composite fabric comprises the following steps:

[0026] a. Material selection: choose PE material as the base fabric;

[0027] b. Base cloth shaping: Use an oven to dry the base cloth to make it pre-shrink and shape. The temperature is controlled at 100°C, the drying time is 50h, and the roll is performed every 10h to ensure the same shrinkage rate of the door width;

[0028] c. One-time squeegeeing and coloring of the front side: the front side of the base cloth is glued with a scraper type glue coating method, which is convenient for controlling the amount of glue applied, and an oven is used to dry the glued base cloth. The temperature in the oven is changed from 90 ~130°C increases successively;

[0029] d. One-time squeegee coloring on the reverse side: the reverse side of the base cloth is glued with a scraper type glue coating method, which is convenient for controlling the amount of glue applied, an...

Embodiment 2

[0037] In the present embodiment, a preparation method of PE and EVA composite fabric comprises the following steps:

[0038] a. Material selection: choose PE material as the base fabric;

[0039] b. Base cloth shaping: Use an oven to dry the base cloth to make it pre-shrink and shape. The temperature is controlled at 110°C, the drying time is 50h, and the roll is performed every 10h to ensure the same shrinkage rate of the door width;

[0040] c. One-time squeegeeing and coloring of the front side: the front side of the base cloth is glued with a scraper type glue coating method, which is convenient for controlling the amount of glue applied, and an oven is used to dry the glued base cloth. The temperature in the oven is changed from 90 ~130°C increases successively;

[0041] d. One-time squeegee coloring on the reverse side: the reverse side of the base cloth is glued with a scraper type glue coating method, which is convenient for controlling the amount of glue applied, an...

Embodiment 3

[0049] In the present embodiment, a preparation method of PE and EVA composite fabric comprises the following steps:

[0050] a. Material selection: choose PE material as the base fabric;

[0051] b. Base cloth shaping: Use an oven to dry the base cloth to make it pre-shrink and shape. The temperature is controlled at 120°C, the drying time is 50h, and the roll is performed every 10h to ensure the same shrinkage rate of the door width;

[0052] c. One-time squeegeeing and coloring of the front side: the front side of the base cloth is glued with a scraper type glue coating method, which is convenient for controlling the amount of glue applied, and an oven is used to dry the glued base cloth. The temperature in the oven is changed from 90 ~130°C increases successively;

[0053] d. One-time squeegee coloring on the reverse side: the reverse side of the base cloth is glued with a scraper type glue coating method, which is convenient for controlling the amount of glue applied, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com