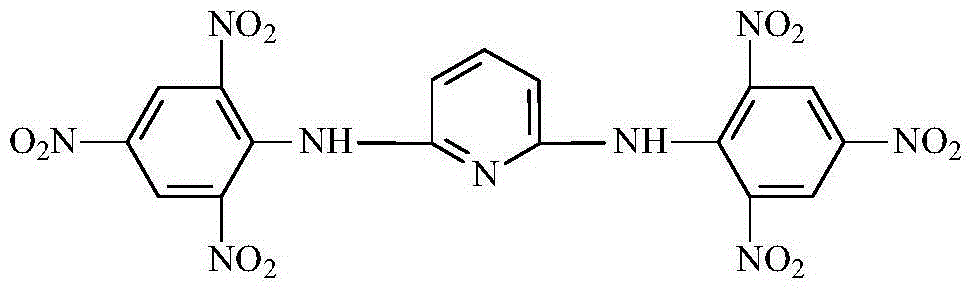

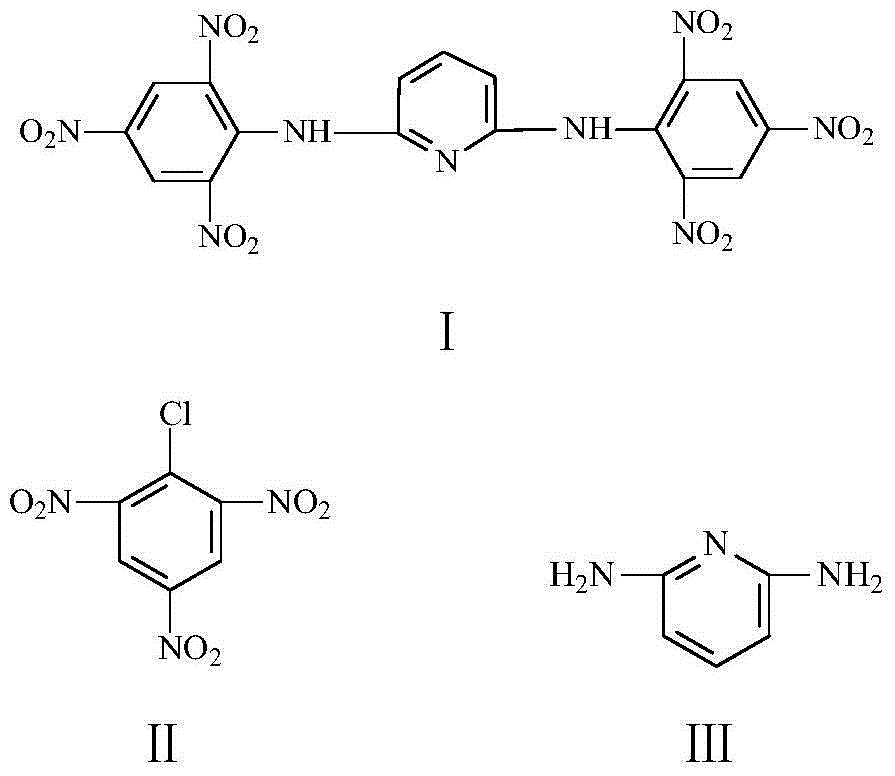

Method for preparing 2, 6-bis-(picrylamino) pyridine

A technology of diaminopyridine and bitter amino group is applied in the field of preparing 2,6-bis-pyridine, which can solve the problems of cumbersome post-processing process, many by-products and high reaction temperature, so as to save the solvent recovery process, reduce the interfacial tension, The effect of increasing the reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

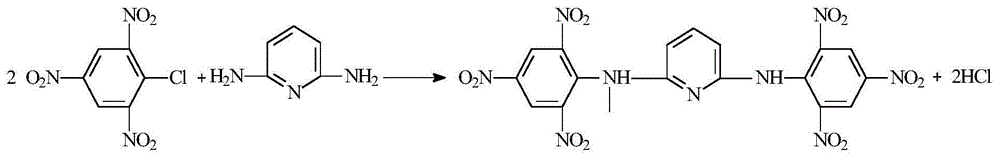

Method used

Image

Examples

Embodiment 1

[0054] Weigh 5.4g of 2,6-diaminopyridine and add it to 100mL of water, stir and raise the temperature, add 0.135g of AE09 into it, raise the temperature to 84°C, and all the solid substances will dissolve; weigh 25.7g of picryl chloride, raise the temperature to 84°C to melt; prepare 160mL of NaHCO with a concentration of 0.6mol / L 3 aqueous solution. Slowly add the mixed solution containing 2,6-diaminopyridine into the picryl chloride liquid, keep the temperature at 84°C, reflux and stir for 3 hours, and drop the prepared NaHCO evenly within 2.5 hours from the reaction timing 3 aqueous solution into the reaction solution. After the reaction was completed, it was filtered, washed with hot water, and recrystallized with methanol to obtain 21.84 g of PAP, with a yield of 83.04%.

Embodiment 2

[0056] Weigh 5.4g of 2,6-diaminopyridine and add it to 200mL of water, stir to raise the temperature, add 0.162g of AE09 into it, raise the temperature to 85°C, and all the solid matter will dissolve; weigh 30.84g of picryl chloride, raise the temperature to 85°C to melt; prepare 480mL of NaHCO with a concentration of 0.2mol / L 3 aqueous solution. Slowly add the mixed solution containing 2,6-diaminopyridine into the picryl chloride liquid, keep the temperature at 85°C, reflux and stir for 3 hours, and drop the prepared NaHCO evenly within 2 hours from the reaction timing 3 aqueous solution into the reaction solution. After the reaction was completed, it was filtered, washed with hot water, and recrystallized with methanol to obtain 17.71 g of PAP, with a yield of 67.34%.

Embodiment 3

[0058] Weigh 5.4g of 2,6-diaminopyridine and add it to 100mL of water, stir to raise the temperature, add 0.19g of AE09 to it, raise the temperature to 85°C, and all the solid substances will dissolve; weigh 25.7g of picryl chloride, heat up to 85°C to melt; prepare 240mL of NaHCO with a concentration of 0.4mol / L 3 aqueous solution. Slowly add the mixed solution containing 2,6-diaminopyridine into the picryl chloride liquid, keep the temperature at 85°C, and react under reflux for 4h. From the reaction timing, add the prepared NaHCO dropwise evenly within 3h 3 aqueous solution into the reaction solution. After the reaction was completed, it was filtered, washed with hot water, and recrystallized with methanol to obtain 21.89 g of PAP, with a yield of 83.23%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com