Brewer yeast strain with variety of tolerance to beer fermentation environment and application thereof

A beer fermentation and tolerance technology, applied in the field of microorganisms, which can solve the problems of single type of resistance, long cycle and limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 has the acquisition of brewer's yeast with various tolerances to the fermentation environment

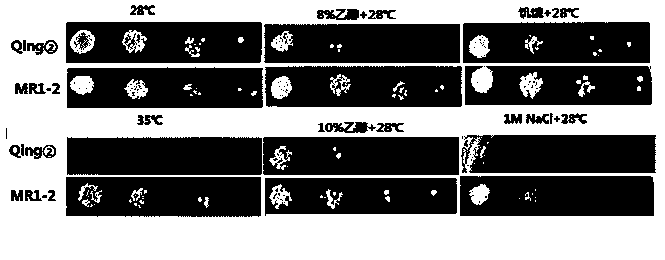

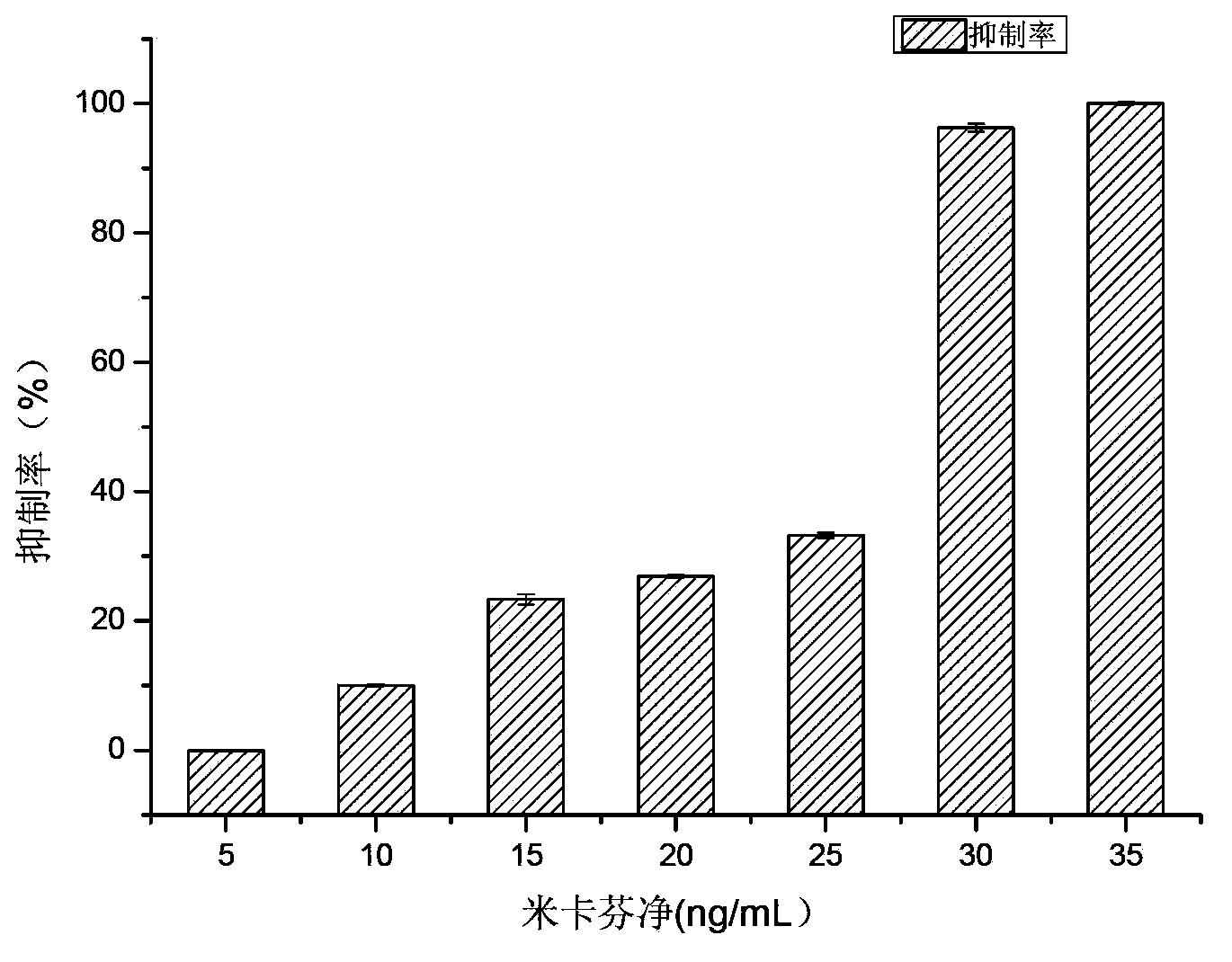

[0023] The starting bacteria were cultured on YEPD solid medium containing different concentrations of micafungin, such as figure 1 As shown, when the concentration of micafungin reached 35ng / mL, the starting strain could not grow, so 35ng / mL was selected as the condition for screening micafungin-resistant strains.

[0024] A strain of brewer's yeast preserved at the School of Bioengineering of Jiangnan University was used as the starting strain, and 35ng / ml micafungin plate was coated after irradiating with a 30W ultraviolet lamp at a distance of 30cm for 20s. Select yeast strains that can grow advantageously under the conditions of 10% ethanol (v / v), 35°C, and 1M NaCl pressure. like figure 2 As shown, MR1-2 exhibited a growth advantage under all stress conditions.

[0025] The obtained yeast was oval, with a diameter of about 6.5 μm; after 3 days of cultiva...

Embodiment 2

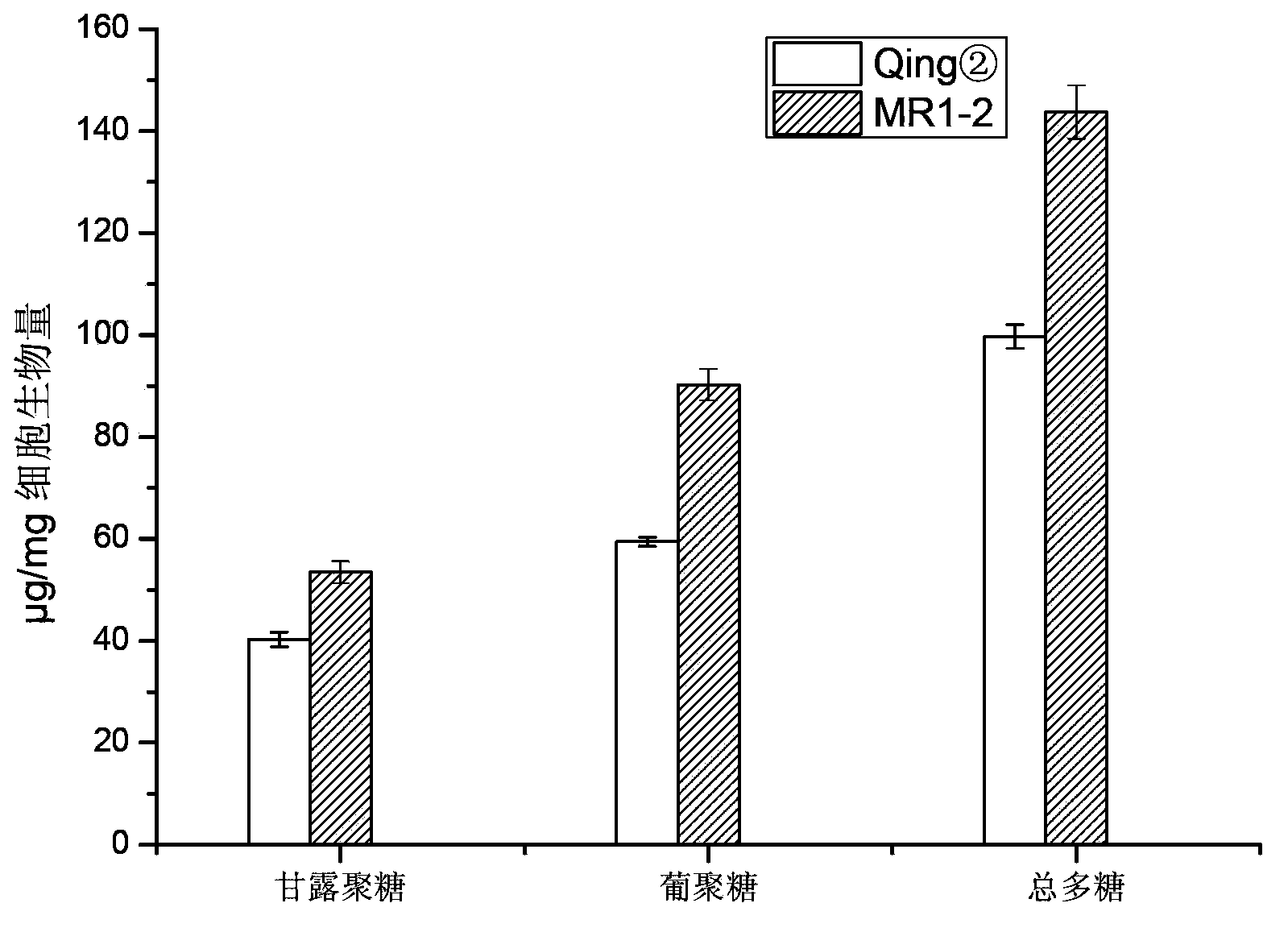

[0026] Example 2 Analysis of Yeast Cell Wall Polysaccharide Components

[0027] The yeast cells cultivated to the stationary phase were collected by centrifugation, and about 100 mg of wet yeast cells were washed 3 times with deionized water. Cells were resuspended in 0.5 mL of 10 mM Tris-HCl (pH 8.0) buffer and transferred to a 5 mL stoppered glass test tube. Add 0.5 g of dry and clean glass beads with a diameter of 400 μm, and then vibrate on a vortex mixer for 5 cycles, each cycle of shaking for 3 min, and ice bath for 3 min. The treated yeast cells were washed 3 times with deionized water, and the precipitate was collected to obtain the yeast cell wall, and vacuum-dried overnight at 45° C. to obtain the dry cell wall.

[0028] Weigh about 10 mg of dry cell wall, add 150 μL of 72% (w / w) sulfuric acid and place at room temperature for 3 hours (appropriate vibration at intervals to promote acidolysis). Then add 0.95mL pure water to dilute and vacuum seal the tube. After sea...

Embodiment 3

[0029] Example 3 High-concentration fermentation performance test of beer yeast with various tolerances to fermentation environments

[0030] Inoculate the 0.5% (w / v) yeast slurry obtained by expansion into a 3L Erlenmeyer flask containing 300mL of 18oP fresh wort, ferment on the upper fermentation plug at 15°C, measure the weight of the fermentation device every day to calculate CO 2 Weight loss, the concentration of the fermentation supernatant was measured by the pycnometer method every 2 days. like Figure 5 As shown, compared with the starting strain, brewer's yeast MR1-2 showed higher fermentation efficiency, and the resulting beer foam was whiter and finer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com