Preparation method of functional lactobacillus acidophilus peptidoglycan and anti-inflammatory activity use of functional lactobacillus acidophilus peptidoglycan

A technology of Lactobacillus acidophilus and peptidoglycan is applied in the field of preparation of functional Lactobacillus acidophilus peptidoglycan, which can solve the problem that the anti-inflammatory activity of Lactobacillus acidophilus peptidoglycan has not been studied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

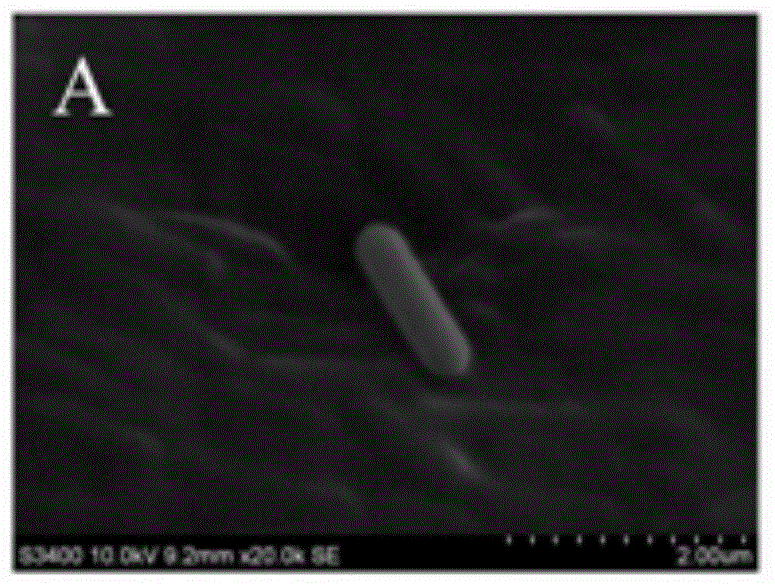

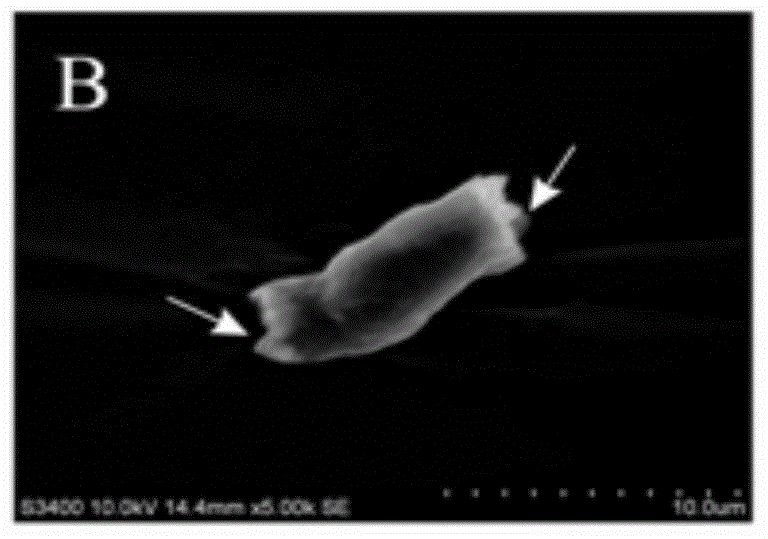

[0019] Preparation of Lactobacillus acidophilus peptidoglycan

[0020] Lactobacillus acidophilus ( Lactobacillus acidophilus ) The preservation number is CGMCC No.8920, inoculate the inoculation amount of 2.0-4.0% by volume, inoculate on MRS medium, and after anaerobic culture at 37°C for 18-24h, centrifuge at 4000-8000g for 15-20min to remove bacteria Then take 1 g of the precipitated bacteria and add it to the SDS solution with a mass fraction of 4%, and pyrolyze it at 100°C for 30 minutes to remove the protein component; take the precipitate and add a solution of trichloroacetic acid with a mass fraction of 10% to the precipitate , to remove teichoic acid; take the precipitate, dialyze the precipitate overnight at 4°C for desalination, pre-freeze the precipitate at -80°C for 6 hours, and quickly put it into a vacuum freeze-drying device for drying at 80-120Pa for 24 hours to obtain The powder is Lactobacillus acidophilus peptidoglycan. Samples were stored in a -40°C freez...

specific Embodiment 2

[0026] The Lactobacillus acidophilus peptidoglycan prepared in Example 1 above was subjected to mass spectrometry (MALDI-TOF / TOF MS) detection and analysis; the Lactobacillus acidophilus peptidoglycan powder was subjected to amino acid analysis and infrared (RI) detection.

[0027] 1. Molecular weight and substructure of peptidoglycan

[0028] Mix 1 microliter of Lactobacillus acidophilus peptidoglycan solution with a concentration of 1 mg / ml and 1 microliter of 50 mg / ml 2,5-dihydroxybenzoic acid. After mixing evenly, take 1 microliter of the mixture and load it. Perform mass spectrometry. The instrument model is FLEX-PC, and the type is ultraflex TOF / TOF. The molecular weight of peptidoglycan detected by this protocol is 875.260 Da, and the specific analysis is shown in Table 1 below.

[0029] Table 1 List of peptidoglycan ion fragments

[0030]

[0031] 2. Analysis of amino acid content

[0032] Use the A200 Amino Nova amino acid analyzer to analyze the composition an...

specific Embodiment 3

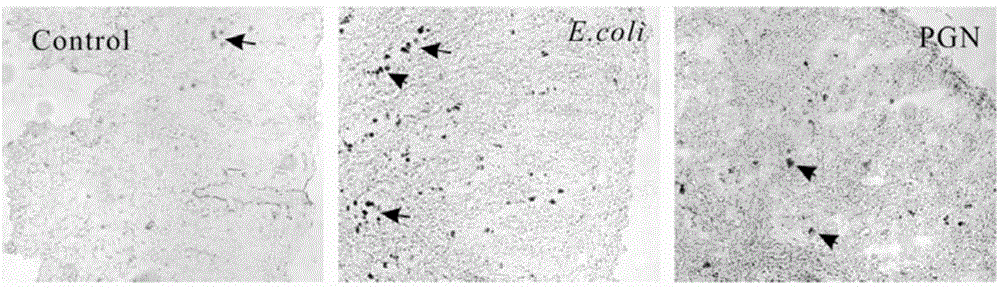

[0038] Anti-inflammatory activity analysis of the Lactobacillus acidophilus peptidoglycan prepared in the above-mentioned embodiment 1

[0039] (1) Using Lactobacillus acidophilus peptidoglycan to regulate the inflammation model of LPS-induced macrophage Raw 264.7, analyze the expression changes of iNOS and COX-2 in the final product, and analyze whether peptidoglycan has a good inhibitory effect Inflammatory substance releasing activity.

[0040] Raw 264.7 cells were cultured in a six-well plate. In the normal group, the adhesion rate reached 60-80%. The RAW 264.7 macrophages were induced by adding LPS at a final concentration of 100ng / ml, and the cytoplasmic protein was extracted after 18 h of continuous culture; the peptidoglycan repair group added final LPS with a concentration of 100ng / ml and peptidoglycan with a final concentration of 25μg / ml, 50μg / ml, 100μg / ml, and 200μg / ml were sequentially cultured for 18 hours to extract cytoplasmic proteins.

[0041] Different gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com