Detection method of minodronic acid by using high performance liquid chromatography

A high-performance liquid chromatography and chromatographic column technology, which is applied in the field of high-performance liquid chromatography for detecting minodronic acid, can solve the problems of less detection of impurity peaks, no strong chromophore, poor separation of impurities, and the like, To achieve the effect of good system applicability and good tailing factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: The method for detecting minodronic acid using high performance liquid chromatography

[0030]Get 10 minodronic acid tablets, grind into powder, make test sample;

[0031] Take 1L of deionized water, add 0.02mol (5.32g) sodium pyrophosphate, 0.322g tetrabutylammonium bromide, after dissolving, add phosphoric acid to adjust the pH to 8.0, take 950ml of the above solution, add 50ml of methanol, and prepare the mobile phase;

[0032] Get need testing sample 150mg, be diluted to 10ml with described mobile phase, obtain need testing sample solution;

[0033] Get described need testing solution 1ml, dilute to dilute 100ml with mobile phase and obtain contrast solution;

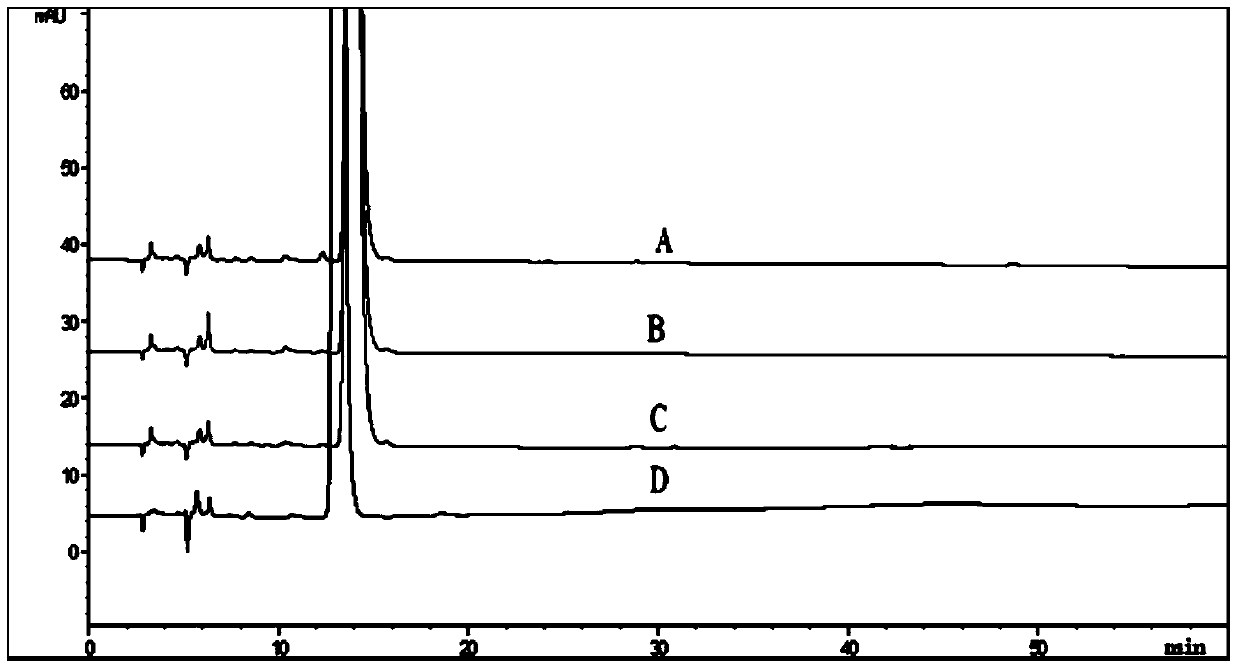

[0034] Adjust the flow rate of the high-performance liquid chromatograph to 1.0ml / min, the detection wavelength to 218nm, take 20 μl of the control solution and inject it into the high-performance liquid chromatograph, and adjust the detection sensitivity so that the peak height of the main com...

Embodiment 2

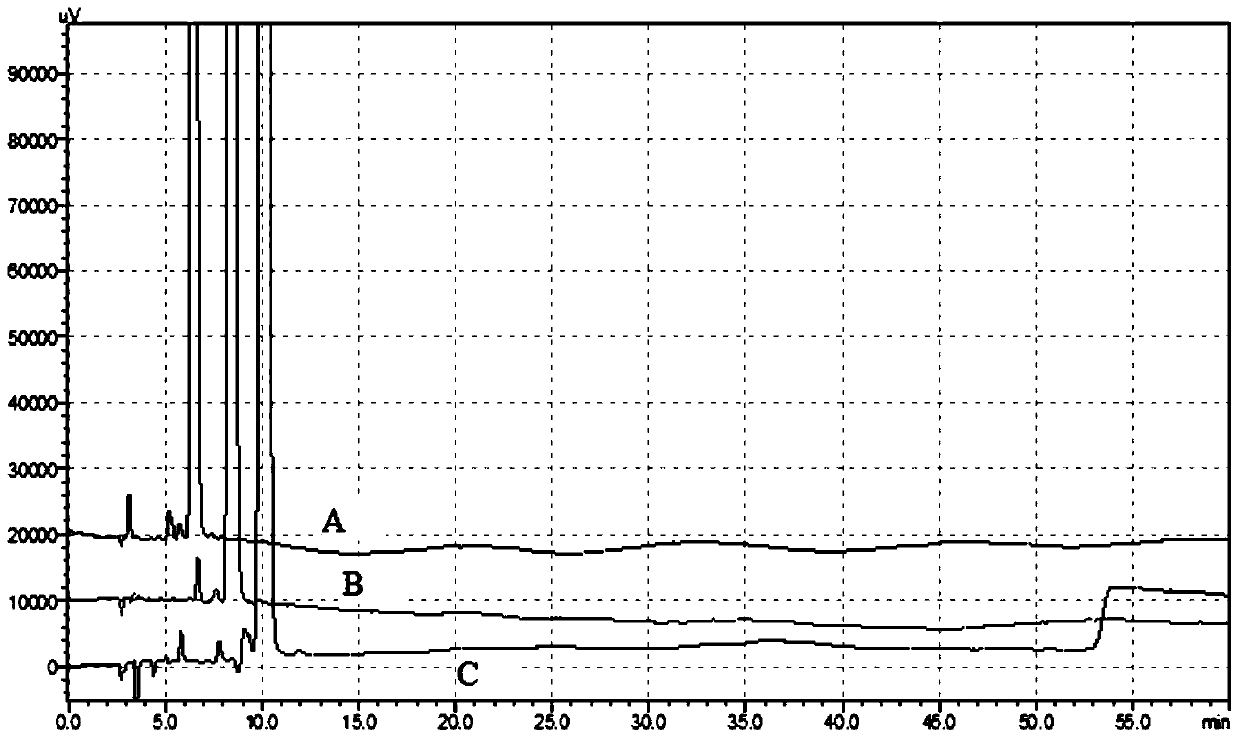

[0037] Embodiment 2: investigation of mobile phase aqueous solution and methanol ratio

[0038] Using the aqueous solution that contains 0.02mol / L sodium pyrophosphate and 0.322g / L tetrabutylammonium bromide prepared according to embodiment 1, the volume ratio of aqueous solution and methanol is respectively 90:10, 95:5, 100:0 Three mobile phases. All the other conditions are identical with embodiment 1, and the high performance liquid chromatogram of gained is shown in figure 2 , where A, B, and C are the chromatograms of the three mobile phases respectively. The resolution, retention time of main peak and number of impurity peaks of different mobile phases are shown in Table 1.

[0039] Table 1 The resolution, main peak retention time and impurity peak quantity of different mobile phase ratios

[0040]

[0041] It can be seen that with the decrease of the organic phase in the mobile phase, the retention time of the main peak is extended, and the separation degree of t...

Embodiment 3

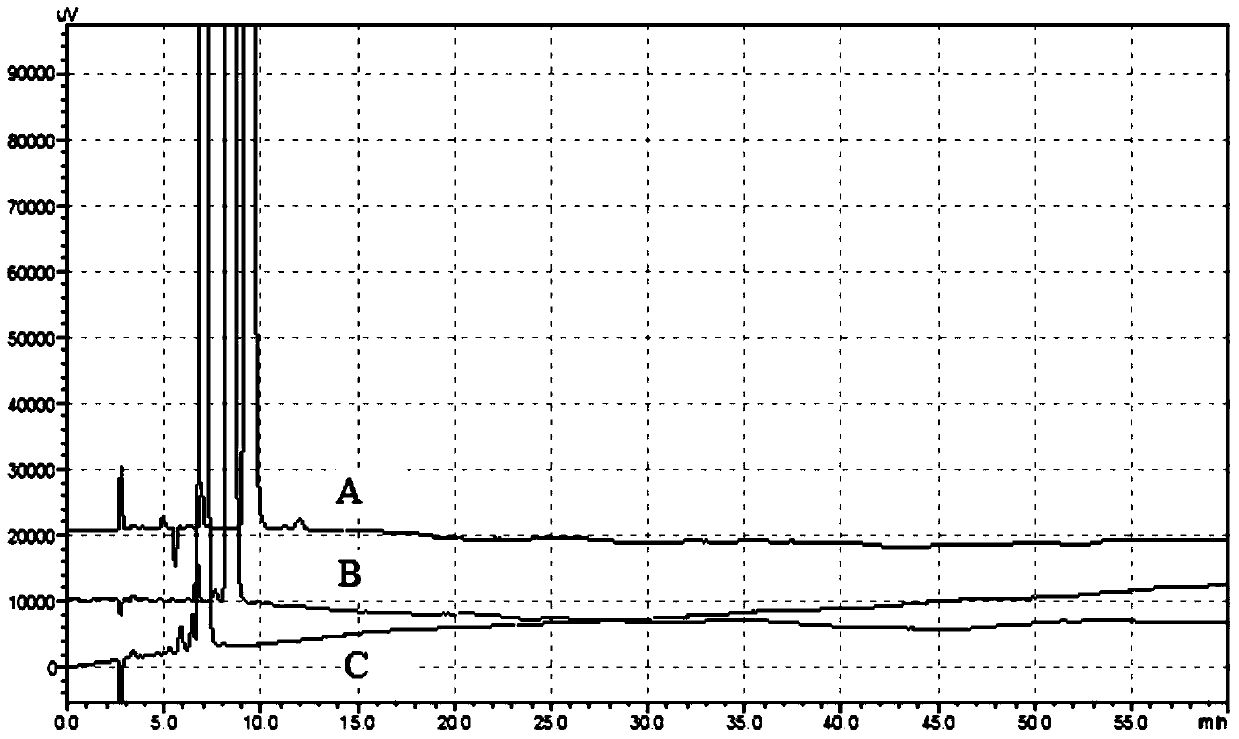

[0042] Embodiment 3: the investigation of sodium pyrophosphate concentration

[0043] Take 1L of deionized water, add 0.02mol (5.32g), 0.03mol (7.98g) and 0.04mol (10.64g) sodium pyrophosphate, 0.322g tetrabutylammonium bromide, add phosphoric acid after dissolving to adjust the pH to 8.0, take 950ml, mixed with 50ml methanol to prepare three mobile phases respectively. All the other conditions are the same as in Example 1. The resulting high performance liquid chromatography see image 3 , where A, B, and C are the chromatograms at concentrations of 0.02, 0.03, and 0.04mol / L sodium pyrophosphate, respectively. The resolution, retention time of main peak and number of impurity peaks of different mobile phases are shown in Table 2.

[0044] Table 2 The degree of separation and the retention time of the main peak and the number of impurity peaks with different concentrations of sodium pyrophosphate

[0045]

[0046]

[0047] As the concentration of sodium pyrophosphate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com