Method for chemically plating Ni-W-P on carbon felt electrode material of modified redox flow battery

A technology of electrode material and modified liquid, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of inability to comprehensively improve the performance of electrode materials and damage to the conductivity of carbon felt electrode materials, and achieve easy operation and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

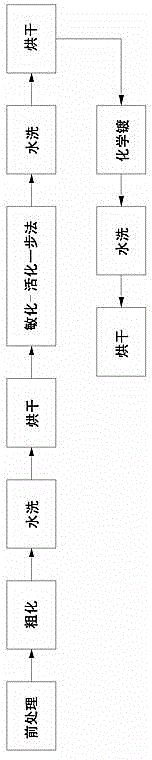

Image

Examples

Embodiment Construction

[0049] The method for electroless plating Ni-W-P modified liquid flow battery carbon felt electrode material of the present invention, the steps are as follows:

[0050]⑴. Pretreatment of raw materials, cleaning, degumming and impurity removal of PAN carbon fiber felt materials. Specific treatment method: pretreatment is to put 5 mm or 5.5 mm or 6 mm thick PAN carbon fiber felt material into a beaker filled with deionized water at room temperature, and clean it in an ultrasonic oscillator for 8 minutes or 10 minutes or 12 minutes. Then put it into a beaker with acetone solution and soak for 25 minutes or 30 minutes or 35 minutes; then put the PAN carbon fiber felt material into NaOH solution (1mol / L) and soak it for 25 minutes at 75°C or 80°C or 85°C min or 30 min or 35 min; finally, put the PAN carbon fiber felt material into deionized water, and wash it with an ultrasonic oscillator for 8 min, 10 min or 12 min, and repeat 3 times until the PAN carbon fiber felt material is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com