Molded product

A molded product and injection molding technology, applied in the field of molded products, can solve problems such as lower elastic modulus, poor crystallinity, and weight loss, and achieve the effects of low water absorption, high crystallinity, and excellent dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

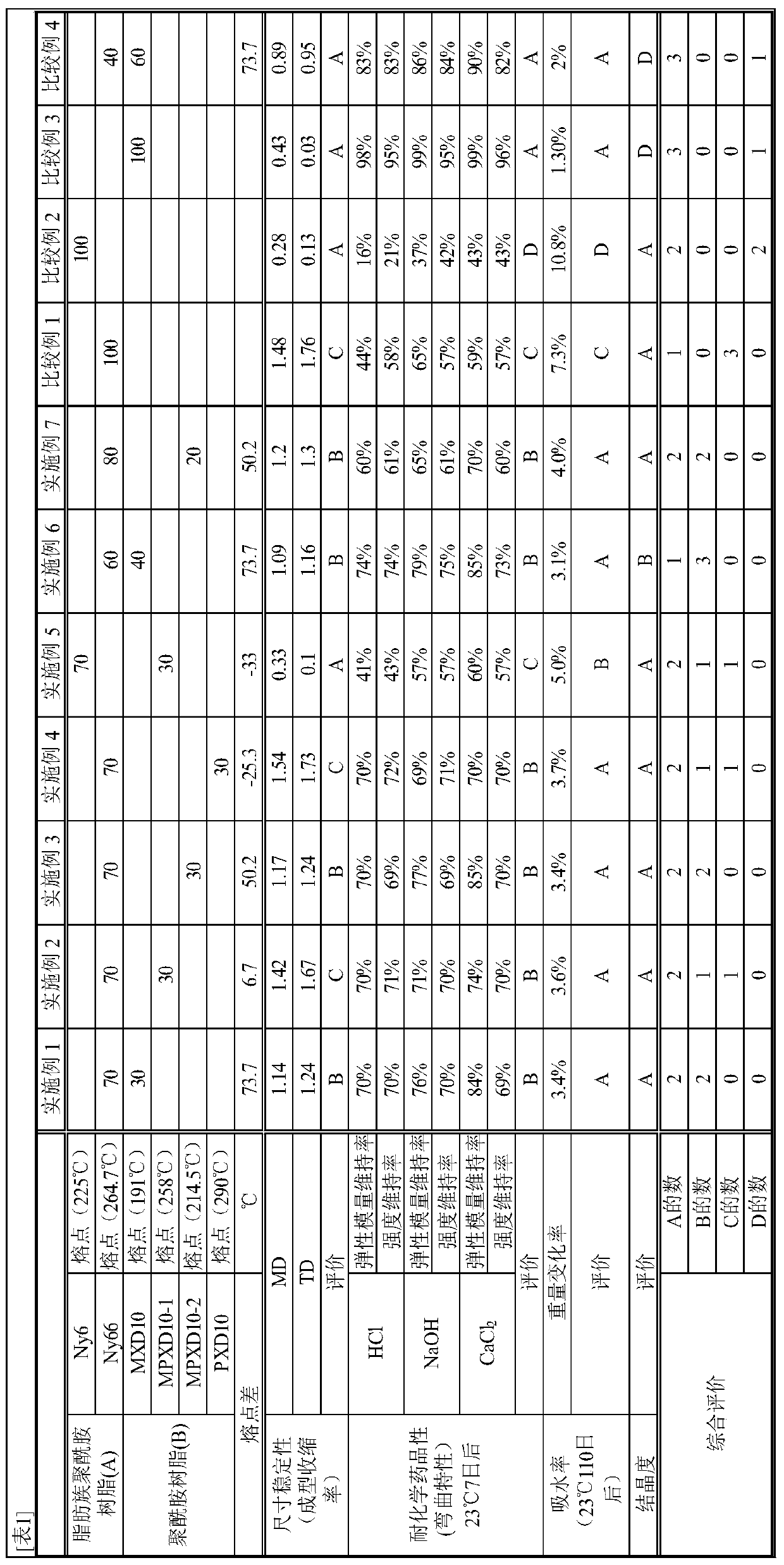

[0128] Hereinafter, the present invention will be more specifically described based on examples, but the present invention should not be limitedly interpreted as the following examples / comparative examples.

[0129] [use material]

[0130] The materials used in Examples and Comparative Examples are as follows.

[0131]

[0132] As the aliphatic polyamide resin (A), the following commercial items were used.

[0133] ·Polyamide 6 (Ny6)

[0134] Manufactured by UBE INDUSTRIES, LTD. 1024B, molecular weight 28,000, melting point 225°C, glass transition point 48°C

[0135] ·Polyamide 66 (Ny66)

[0136] CM3001N manufactured by Toray Co., Ltd., molecular weight 25,000, melting point 265°C, glass transition point 50°C

[0137]

[0138] As the polyamide resin (B), those produced in the following production examples 1 to 4 were used.

manufacture example 1

[0139]

[0140] After heating sebacic acid (manufactured by Ito Oil Co., Ltd., TA GRADE) at 170°C to melt in the reactor, m-xylylenediamine (manufactured by Mitsubishi Gas Chemical Co., Ltd., MXDA) was added while stirring the contents. While m-xylylenediamine was slowly added dropwise at a molar ratio of 1:1 to sebacic acid, the temperature was raised to 240°C. After completion of the dropwise addition, the temperature was raised to 260°C. After completion of the reaction, the contents were taken out in the form of strands and granulated with a granulator. The obtained pellets were put into a drum, and solid-phase polymerization was carried out under reduced pressure to obtain a polyamide resin with adjusted molecular weight.

[0141] The polyamide resin (MXD10) measured by the following method has a melting point of 191°C, a glass transition point of 60°C, a number average molecular weight of 30,000, and an oxygen permeability coefficient of 0.8cc·mm / m 2 day atm.

[014...

manufacture example 2

[0143]

[0144] Weigh and add accurately weighed sebacic acid (manufactured by Ito Oil Co., Ltd. GRADE) 8950g (44 moles), calcium hypophosphite 13.7401g (150ppm in terms of phosphorus atomic concentration in the polyamide resin), sodium acetate 10.6340g. In addition, the molar ratio of calcium hypophosphite and sodium acetate was 1.0. After the inside of the reaction vessel was sufficiently replaced with nitrogen, the pressure was increased to 0.3 MPa with nitrogen, and the temperature was raised to 160° C. while stirring to uniformly melt sebacic acid.

[0145] Next, 6026 g (44 mol) of p-xylylenediamine (PXDA) was dropped over 170 minutes with stirring. During this period, the internal temperature was continuously raised to 281°C. In the dropping process, the pressure is controlled at 0.5 MPa, and the generated water is discharged out of the system through a dephlegmator and a condenser. The temperature of the partial condenser is controlled within the range of 145-147°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile modulus | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com