Cleaning agent and method for producing silicon carbide single-crystal substrate

A technology of silicon carbide single crystal and manufacturing method, which is applied in the preparation of detergent mixture compositions, chemical instruments and methods, detergent compositions, etc., can solve the problems of insufficient effect, low chemical reactivity, insufficient cleaning effect, etc. problems, to achieve the effect of reducing workability and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

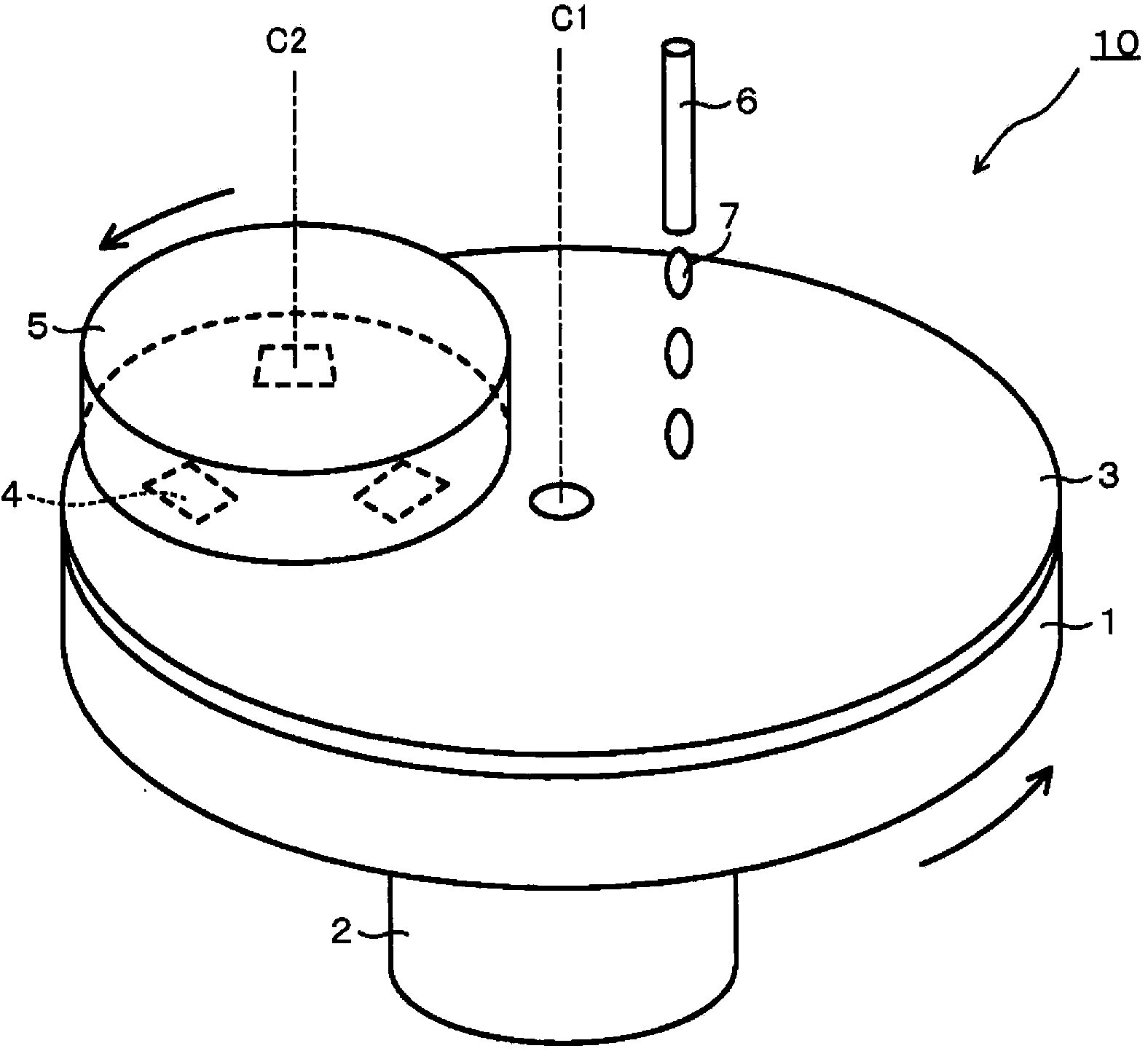

Method used

Image

Examples

Embodiment

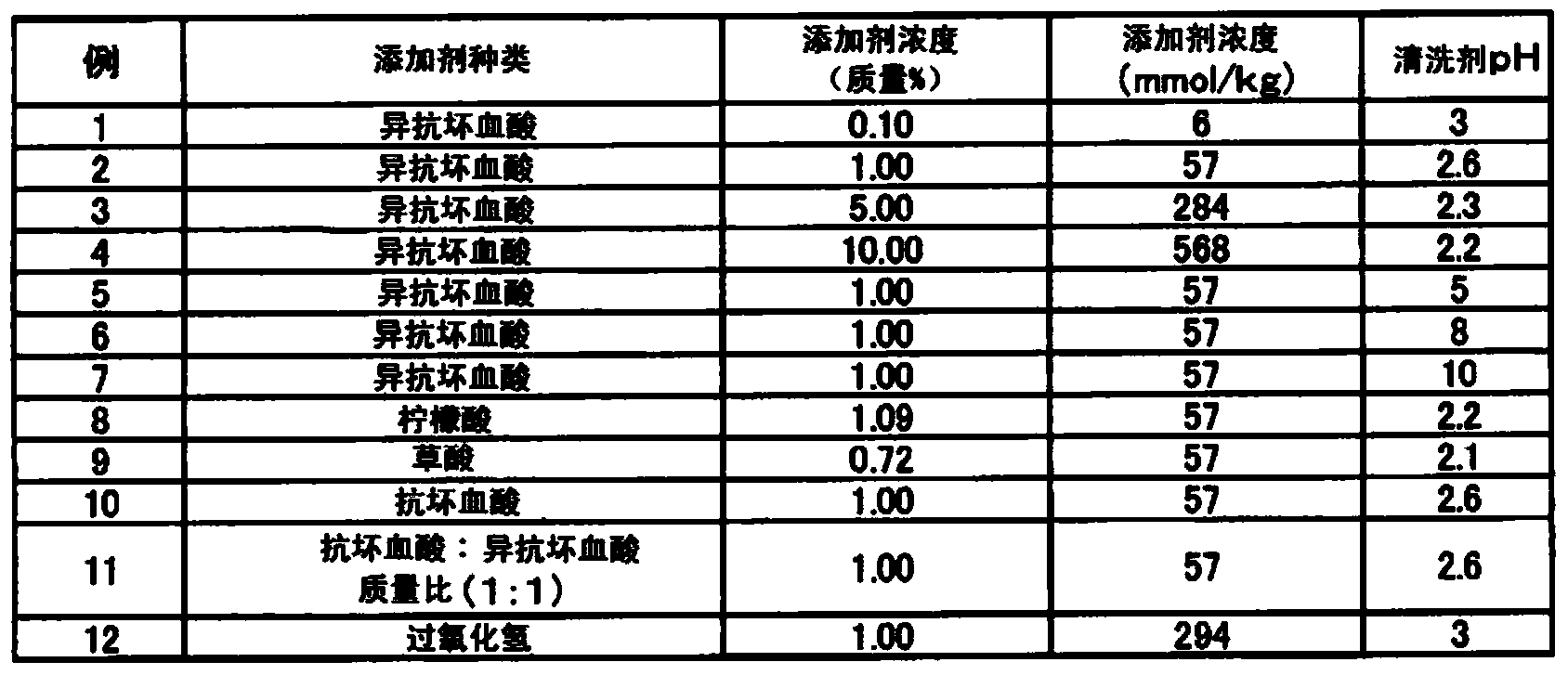

[0071] Hereinafter, the present invention will be more specifically described by way of examples and comparative examples, but the present invention is not limited to these examples. Examples 1-5, Example 10 and Example 11 are examples of the present invention, and Examples 6-9 and Example 12 are comparative examples.

example 1~12

[0073] (1) Preparation of cleaning agent

[0074] Cleaning agents having the compositions shown in Table 1 were prepared in the manner shown below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com