Alprostadil lipid microsphere injection and preparation method thereof

A technology for alprostadil and injection, which is applied in the field of alprostadil lipid microsphere injection and its preparation, can solve the problems of lack of practicability and unsatisfactory product quality, and achieves enhancement of aseptic control process and improvement of aseptic assurance level and production efficiency, the effect of high sterility assurance level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

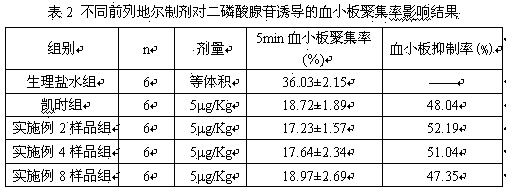

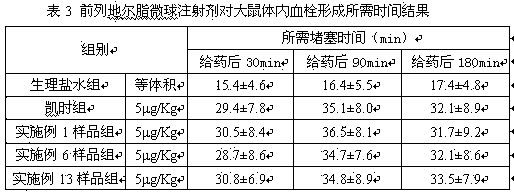

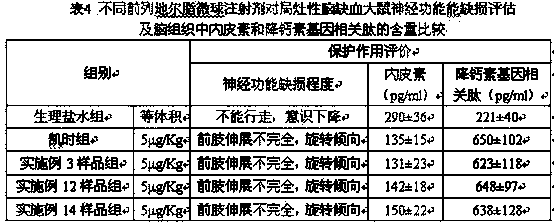

Examples

Embodiment 1

[0026] (1) Weigh 7mg alprostadil, 18g egg yolk lecithin, 2.4g oleic acid and 100g soybean oil into a container, use a high-speed shearing machine to disperse to dissolve to form an oil phase, and heat to 50-70°C for use;

[0027] (2) Weigh 0.01g disodium edetate, 22.1g glycerin and 850g water for injection into the container, after fully dissolving, adjust the pH of the aqueous phase to 9.0 with sodium hydroxide solution, and heat to 50-70°C for use;

[0028] (3) Under the protection of nitrogen, slowly add the oil phase to the water phase under the action of a high-speed shearing machine at a shearing speed of 10000rpm and a shearing time of 3min to form colostrum;

[0029] (4) Emulsify the prepared colostrum with a high-pressure microfluidizer, the emulsification pressure is 5000-18000 psi, and the number of emulsification cycles is 3-8;

[0030] (5) After filling the prepared emulsion with nitrogen, filling, stoppering, and capping, put it in a rotary water bath sterilization cabine...

Embodiment 2

[0032] (1) Weigh 7mg alprostadil, 18g egg yolk lecithin, 2.4g oleic acid and 100g soybean oil into a container, use a high-speed shearing machine to disperse to dissolve to form an oil phase, and heat to 50-70°C for use;

[0033] (2) Weigh 0.05g disodium edetate, 22.1g glycerin and 850g water for injection into the container, after fully dissolving, adjust the pH of the aqueous phase to 9.0 with sodium hydroxide solution, and heat to 50-70°C for use;

[0034] (3) Under the protection of nitrogen, slowly add the oil phase to the water phase under the action of a high-speed shearing machine at a shearing speed of 10000rpm and a shearing time of 3min to form colostrum;

[0035] (4) Emulsify the prepared colostrum with a high-pressure microfluidizer, the emulsification pressure is 5000-18000 psi, and the number of emulsification cycles is 3-8;

[0036] (5) After filling the prepared emulsion with nitrogen, filling, stoppering, and capping, put it in a rotary water bath sterilization cabine...

Embodiment 3

[0038] (1) Weigh 7mg alprostadil, 18g egg yolk lecithin, 2.4g oleic acid and 100g soybean oil into a container, use a high-speed shearing machine to disperse to dissolve to form an oil phase, and heat to 50-70°C for use;

[0039] (2) Weigh 0.2g disodium edetate, 22.1g glycerin and 850g water for injection into the container, after fully dissolving, adjust the pH of the aqueous phase to 9.0 with sodium hydroxide solution, and heat to 50-70°C for use;

[0040] (3) Under the protection of nitrogen, slowly add the oil phase to the water phase under the action of a high-speed shearing machine at a shearing speed of 10000rpm and a shearing time of 3min to form colostrum;

[0041] (4) Emulsify the prepared colostrum with a high-pressure microfluidizer, the emulsification pressure is 5000-18000 psi, and the number of emulsification cycles is 3-8;

[0042] (5) After filling the prepared emulsion with nitrogen, filling, stoppering, and capping, put it in a rotary water bath sterilization cabinet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com