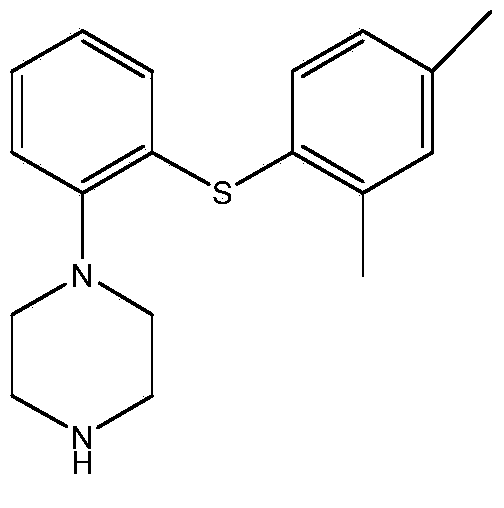

Orally disintegrating pharmaceutical composition and preparation method thereof

A technology for orally disintegrating tablets and drugs, which is applied in drug combinations, pharmaceutical formulations, medical preparations containing active ingredients, etc., can solve the problem of low drug loading and encapsulation efficiency, poor production feasibility, and particle size of pellets or granules. major issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 10g of vortioxetine hydrobromide, 20g of gastric-soluble polyacrylic acid resin EPO, and 1g of diethyl phthalate and dissolve them in 20ml of absolute ethanol. ~600rpm water, after the precipitation is complete, suction filtration, the obtained powder is dried in a vacuum drying oven for 24 hours, taken out, and stored in a closed container in a cool place to obtain vortioxetine hydrobromide taste-masking microcapsules.

[0027] Tablet prescription:

[0028] Vortioxetine Hydrobromide Taste-Masked Microcapsules

[0029] Weigh the above-mentioned materials (except magnesium stearate) and pour them into a three-dimensional mixer for mixing, then add magnesium stearate for mixing; the mixed materials are poured into the hopper of a tablet press, and the tablet weight and pressure are adjusted to perform tablet compression. The hardness of the compressed tablet is maintained at 30-50N; the product is obtained by cold-forming double-aluminum blister packs.

Embodiment 2

[0031] Weigh 20g of vortioxetine hydrobromide, 80g of gastric-soluble polyacrylic acid resin EPO and 2g of diethyl phthalate and dissolve them in 20ml of absolute ethanol. ~600rpm water, after the precipitation is complete, suction filtration, the obtained powder is dried in a vacuum drying oven for 24 hours, taken out, and stored in a closed container in a cool place to obtain vortioxetine hydrobromide taste-masking microcapsules.

[0032] Tablet prescription:

[0033] Vortioxetine Hydrobromide Taste-Masked Microcapsules

[0034] Weigh the above-mentioned materials (except magnesium stearate) and pour them into a three-dimensional mixer for mixing, then add magnesium stearate for mixing; the mixed materials are poured into the hopper of a tablet press, and the tablet weight and pressure are adjusted to perform tablet compression. The hardness of the compressed tablet is maintained at 30-50N; the product is obtained by cold-forming double-aluminum blister packs.

Embodiment 3

[0036] Weigh 20g of vortioxetine hydrobromide, 80g of gastric-soluble polyacrylic acid resin EPO and 2g of diethyl phthalate and dissolve them in 20ml of absolute ethanol. ~600rpm water, after the precipitation is complete, suction filtration, the obtained powder is dried in a vacuum drying oven for 24 hours, taken out, and stored in a closed container in a cool place to obtain vortioxetine hydrobromide taste-masking microcapsules.

[0037] Tablet prescription:

[0038] Vortioxetine Hydrobromide Taste-Masked Microcapsules

[0039] Weigh the above materials (except magnesium stearate) into a three-dimensional mixer and mix for 30 minutes, then add magnesium stearate and mix for 1 to 2 minutes; pour the mixed materials into the hopper of the tablet machine, adjust the tablet weight and pressure, Tablet compression is carried out so that the hardness of the compressed tablet is maintained at 30-50N; double aluminum blisters are cold-formed and packaged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com