Special coating for modified cold primer oil pipeline, and preparation method thereof

An oil pipeline and base technology, which is applied in the field of pipeline coatings and their preparation, special coatings for modified cold base oil pipelines and their preparation, can solve the problems of low film-forming hardness and slow drying, and achieve fast drying, Effect of improving dryness, excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] First take 20% of modified resin, 60% of asphalt liquid, 10% of 52# paraffin, 1% of auxiliary agent, 10% of talcum powder, calculated by weight percentage; wherein auxiliary agent is calculated by weight percentage: titanium dioxide: 25%, cloud silk Mother powder: 75%.

[0033] Put 35% chlorinated rubber, 52# paraffin, additives, into the dispersing tank, start the agitator to stir slowly, the stirring speed is 300 rpm, after stirring for 30 minutes, visually observe that it is uniform and transparent, then talcum powder Add in the stirring state, adjust the rotation speed to 600 rpm, and the stirring time is 30 minutes, control the temperature of the dispersing cylinder ≤ 45°C through the jacket method, and finally add 50% asphalt liquid, and stir while adding, adjust the rotation speed to 800 rpm / min, after stirring for one hour, the viscosity is detected to be ≥90s, and the solid content is ≥70%, and the finished product is obtained.

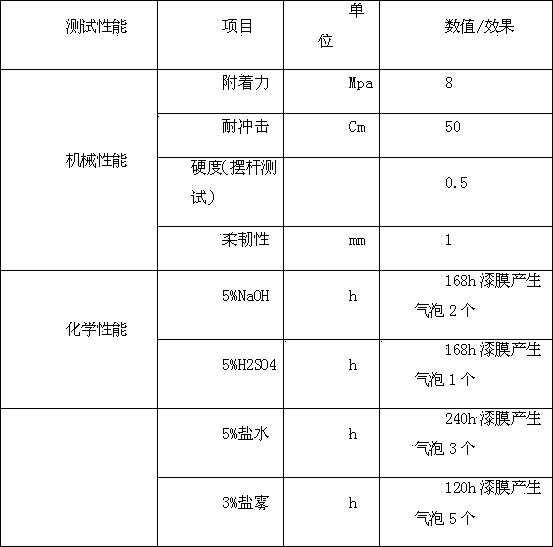

[0034] Effect of use: Make 5 ...

Embodiment 2

[0038] First take 25% of modified resin, 50% of asphalt liquid, 8% of 52# paraffin wax, 2% of auxiliary agent, 15% of talcum powder, calculated by weight percentage; wherein auxiliary agent is calculated by weight percentage: titanium dioxide: 28%, cloud silk Mother flour: 72%.

[0039] Put 35% chlorinated rubber, 52# paraffin, additives, into the dispersing tank, start the agitator to stir slowly, the stirring speed is 300 rpm, after stirring for 30 minutes, visually observe that it is uniform and transparent, then talcum powder Add in the stirring state, adjust the rotation speed to 600 rpm, and the stirring time is 30 minutes, control the temperature of the dispersing cylinder ≤ 45°C through the jacket method, and finally add 50% asphalt liquid, and stir while adding, adjust the rotation speed to 800 rpm / min, after stirring for one hour, the viscosity is detected to be ≥90s, and the solid content is ≥70%, and the finished product is obtained.

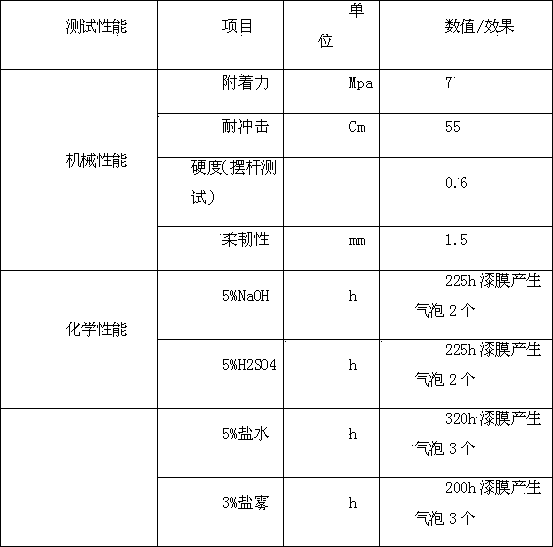

[0040] Effect of use: Make ...

Embodiment 3

[0044] First get 30% of modified resin, 50% of asphalt liquid, 52# paraffin 5%, auxiliary agent 2%, talcum powder 13%, by weight percentage; wherein auxiliary agent is by weight percentage: titanium dioxide: 26%, Mica powder: 74%.

[0045] Put 35% chlorinated rubber, 52# paraffin, additives, into the dispersing tank, start the agitator to stir slowly, the stirring speed is 300 rpm, after stirring for 30 minutes, visually observe that it is uniform and transparent, then talcum powder Add in the stirring state, adjust the rotation speed to 600 rpm, and the stirring time is 30 minutes, control the temperature of the dispersion cylinder to ≤45°C through the jacket method, and finally add 50% asphalt liquid, and stir while adding, adjust the rotation speed to 800 rpm / min, after stirring for one hour, the viscosity is detected to be ≥90s, and the solid content is ≥70%, and the finished product is obtained.

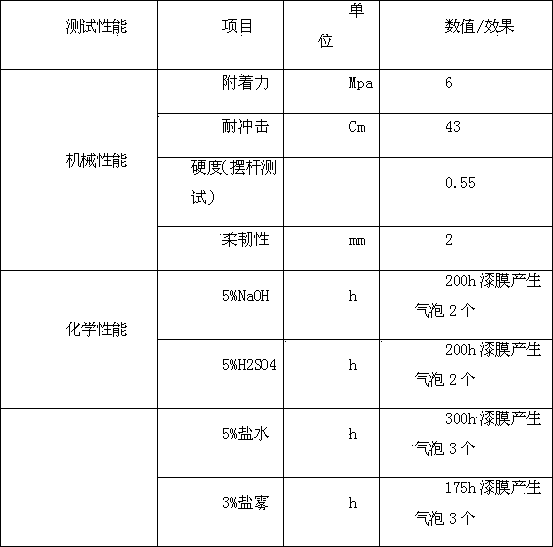

[0046] Effect of use: Make 5 test panels with the above formula, one of w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com