Bifunctional micro-encapsulation phase-change energy storage material with photo-catalysis property and preparation method thereof

A phase-change energy storage material and energy storage material technology, applied in the field of dual-functional microcapsule phase-change energy storage materials with photocatalytic properties and its preparation, can solve problems such as failure, easy leakage, and difficult to stabilize, and achieve heat The release and storage process is stable and safe, with high chemical stability and good photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

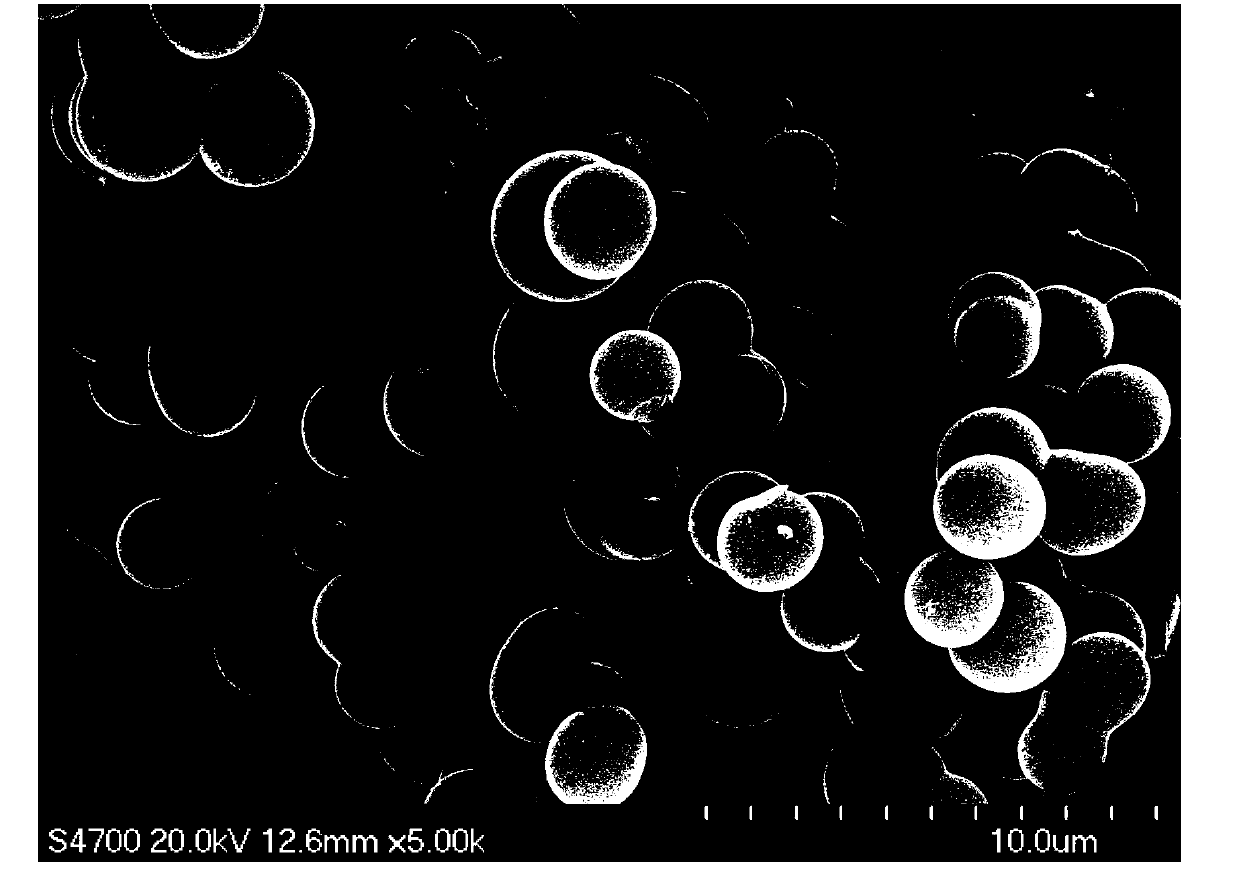

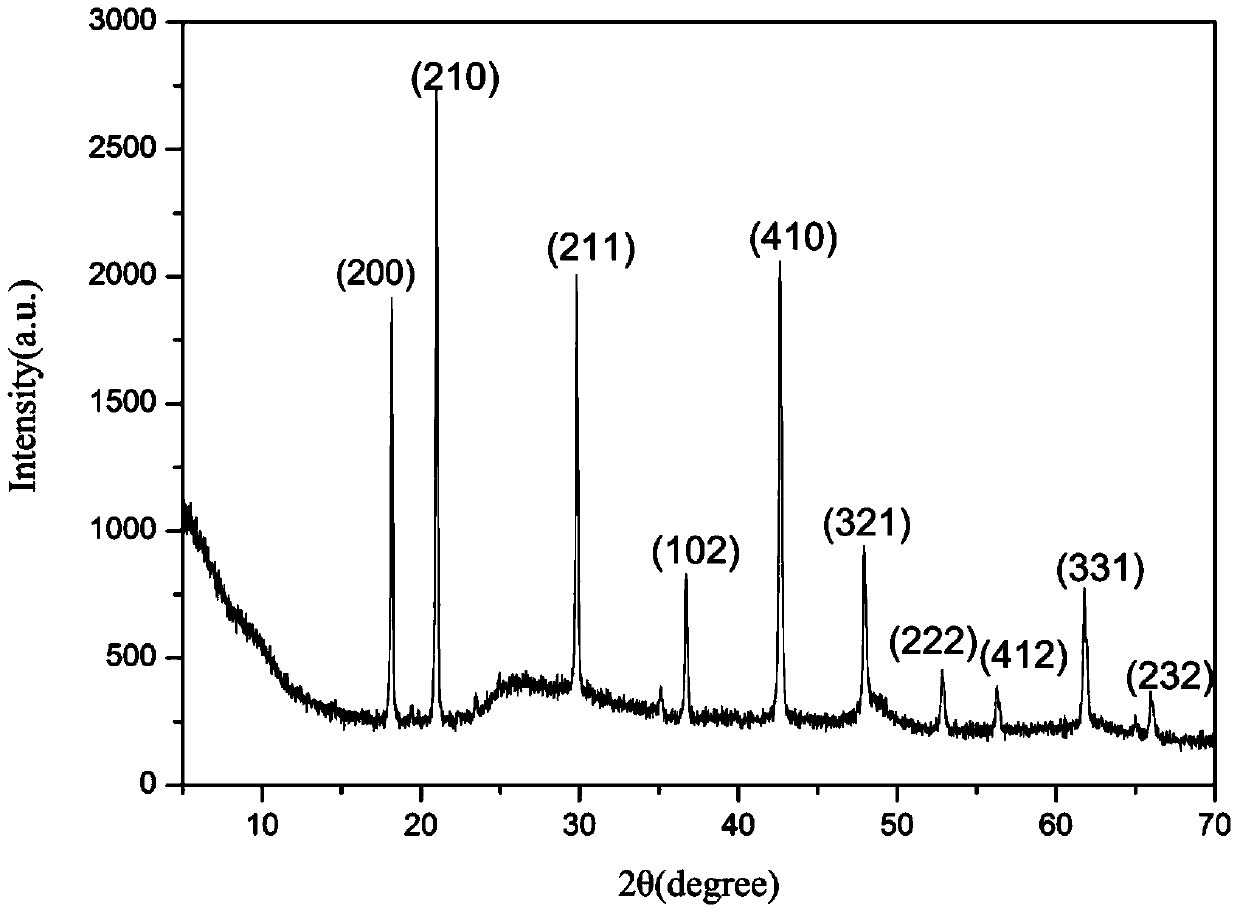

[0042] Add 35g of n-eicosane to 250mL formamide solution containing 8.3g of anionic surfactant (sodium lauryl sulfate), then add 15g of tetrabutyl titanate to the above solution, and place in an oil bath at 45°C , stirred and emulsified at a speed of 600 rpm for 2.5 hours to form a stable O / W emulsion, and uniformly disperse tetrabutyl titanate around the emulsified oil droplets. Slowly add 150mL formamide solution containing 12.5g deionized water dropwise, so that tetrabutyl titanate undergoes hydrolysis and polycondensation reaction on the surface of emulsified oil droplets, continue to stir for 5-6h, add 5g of sodium fluoride powder, and stir at 70°C for 24h Then stop stirring and cool naturally to obtain a precipitation solution, which is filtered, washed with absolute ethanol and deionized water, and then air-dried to obtain a microcapsule phase-change energy storage material coated with crystalline titanium dioxide and n-eicosane. The surface is smooth and dense, with a ...

Embodiment 2

[0044] 35g n-octadecane was added to 250mL formamide solution containing 10g cationic surfactant (hexadecyltrimethylammonium bromide), then 15g tetraisopropyl titanate was added to the above solution, at 45 °C in an oil bath, stir and emulsify at a speed of 800 rpm for 2.5 hours to form a stable O / W emulsion, and evenly disperse tetraisopropyl titanate around the emulsified oil droplets. Slowly add 150mL formamide solution containing 10g deionized water dropwise, so that tetraisopropyl titanate undergoes hydrolysis and polycondensation reaction on the surface of emulsified oil droplets, continue stirring for 5-6h, add 5g ammonium fluoride powder, and stir at 70°C for 24h Then stop stirring and cool naturally to obtain a precipitation solution, which is filtered, washed with absolute ethanol and deionized water, and then air-dried to obtain a microcapsule phase-change energy storage material coated with n-octadecane in crystalline titanium dioxide. The surface is smooth and den...

Embodiment 3

[0046] Add 30g n-nonadecane to 250mL acetonitrile / ethanol mixed solvent (volume ratio is 1 / 3) containing 10g nonionic surfactant (PEO-PPO-PEO), then add 20g tetrabutyl titanate to the above In the solution, stir and emulsify at 600 rpm for 2.5 hours in an oil bath at 45° C. to form a stable O / W emulsion, and evenly disperse tetrabutyl titanate around the emulsified oil droplets. Slowly add 150mL of acetonitrile / ethanol mixed solvent containing 10g of deionized water (volume ratio: 1 / 3), so that tetrabutyl titanate undergoes hydrolysis and polycondensation reaction on the surface of emulsified oil droplets, continue stirring for 5-6h, add 5g of chloride Ammonium powder, stirred at 70°C for 24 hours, then stopped stirring and cooled naturally to obtain a precipitation solution, which was filtered, washed with absolute ethanol and deionized water, and dried naturally to obtain crystalline titanium dioxide coated n-nonadecane The microcapsule phase change energy storage material h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com