Method for coating workpiece with complex inner cavity structure

A technology for workpieces and inner chambers, applied in the field of coating preparation, can solve the problems of inability to protect and complicate the coating of cooling channels in hollow complex structures, achieve low production costs, high production efficiency, and improve corrosion resistance and high temperature resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

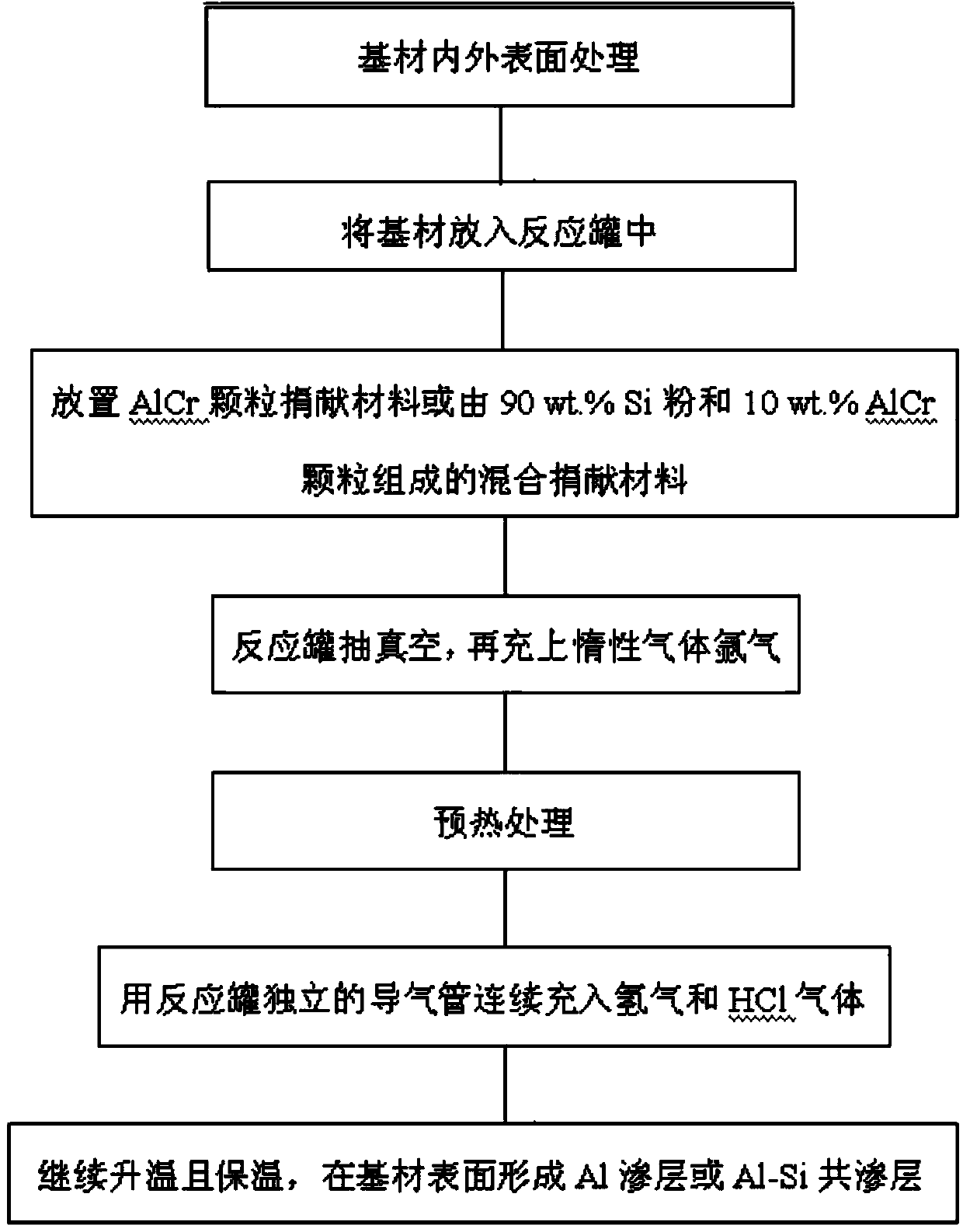

Method used

Image

Examples

Embodiment 1

[0032] A method suitable for coating a workpiece with a complex inner cavity structure, the workpiece uses a nickel-based alloy as a substrate, and AlCr particles with an average diameter of 10 mm are used as a donor material.

[0033] The inner and outer surfaces of the nickel-based alloy substrate are treated by particle flow process and sandblasting respectively, and then the nickel-based alloy substrate is purified by ultrasonic cleaning; the nickel-based alloy substrate is placed in the half-height center of the reaction tank; Place AlCr particles with an average diameter of 10mm on the bottom of the nickel-based alloy substrate; vacuumize the reaction tank, and the pressure of the tank is about 1 to 2 mbar; after the reaction tank is heated to 200 ° C, the wet moisture absorbent is completely dried; The independent air guide tube of the tank is filled with hydrogen and HCl gas with a ratio of 4:1, and the tank pressure is kept at 900 mbar; the temperature is raised to 108...

Embodiment 2

[0035] The content of this embodiment is basically the same as that of Embodiment 1, and its difference mainly lies in:

[0036] 1) Donate materials with 90wt.% Si powder and 10wt.% AlCr particles.

[0037] 2) Obtain an Al-rich Al-Si co-infiltrated layer (the mass fraction of Al is more than 30%) in the inner and outer layers of the complex structure of the nickel-based alloy, and the thickness is about 30 μm.

[0038] 3) The infiltrated Al and Si react with Ni to form NiAl(Si) ternary intermetallic compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com