Double-layer transparent conducting thin film and preparation method thereof

A transparent conductive film, double-layer technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of easy reduction, high price, poor stability, etc., to achieve non-toxic materials and low cost , to achieve the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

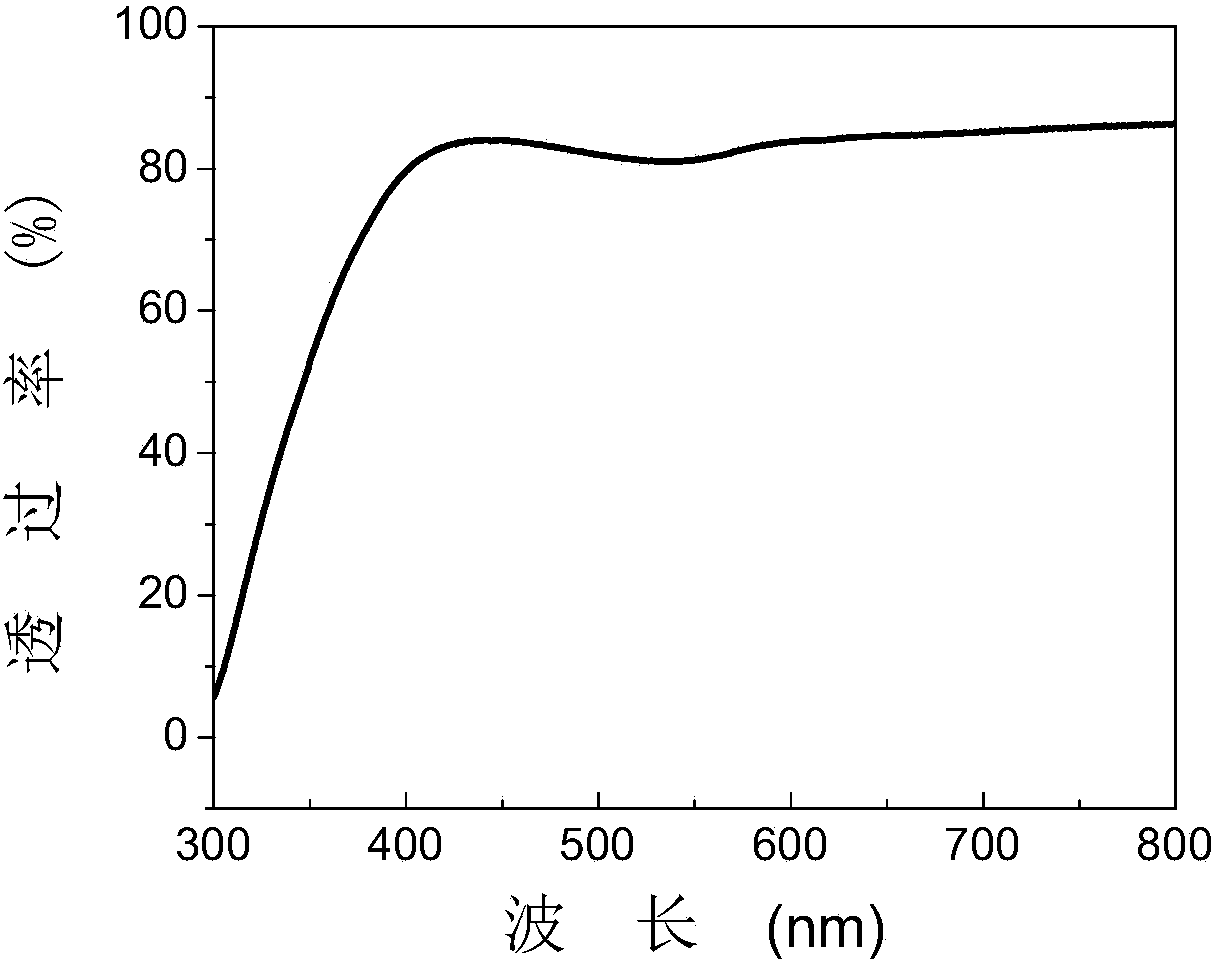

Image

Examples

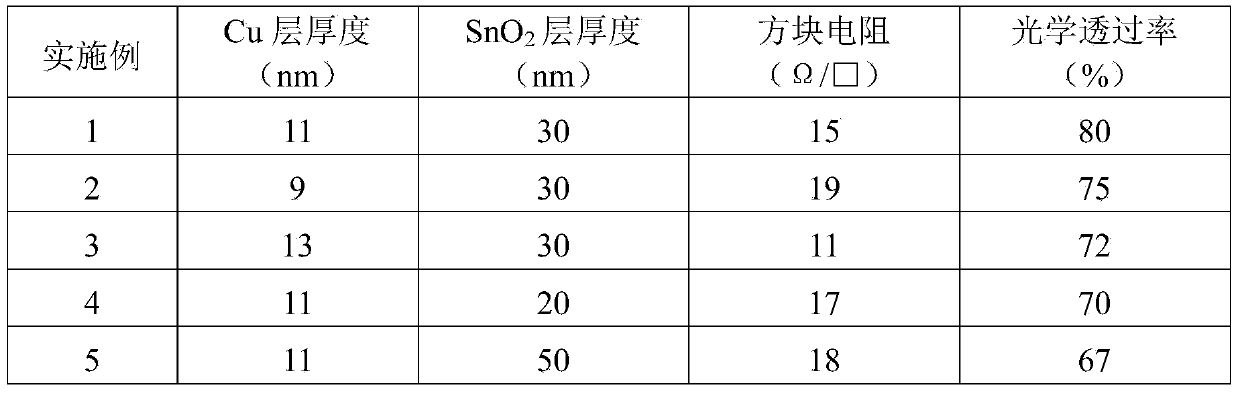

Embodiment 1

[0026] (1) SnO 2 The target and Cu target are loaded into the magnetron sputtering chamber; SnO 2 SnO in target 2 The purity of Cu is 99.5%; the purity of Cu in the Cu target is 99.99%.

[0027] Then, the quartz substrate was ultrasonically cleaned with acetone, absolute ethanol and deionized water successively, dried with high-purity nitrogen, and placed in a magnetron sputtering chamber; the distance between the target and the quartz substrate was 90mm;

[0028] (2) Pump the background vacuum of the magnetron sputtering system to 1.0×10 -6 Torr; feed 60sccm of argon and 4sccm of oxygen (the ratio of argon to oxygen is 15:1), the total sputtering pressure is adjusted to 5mTorr; the sputtering power is 200W, and the deposition is performed to obtain 30nm thick SnO 2 film.

[0029] Ar and O 2 The purity is above 99.99%;

[0030] (3) Pump the vacuum degree of the magnetron sputtering system to 1.0×10 -6 Torr; argon gas of 60 sccm was introduced, and the pressure was adjus...

Embodiment 2

[0034] (1) SnO 2 The target and Cu target are loaded into the magnetron sputtering chamber; SnO 2 SnO in target 2 The purity of Cu is 99.5%; the purity of Cu in the Cu target is 99.99%;

[0035] Then, the quartz substrate was ultrasonically cleaned with acetone, absolute ethanol and deionized water, dried with high-purity nitrogen, and placed in a magnetron sputtering chamber; the distance between the target and the quartz substrate was 60 mm.

[0036] (2) Pump the background vacuum of the magnetron sputtering system to 5.0×10 -5 Torr. 60 sccm of argon gas and 4 sccm of oxygen gas (the ratio of argon to oxygen is 15:1) were introduced, and the total sputtering gas pressure was adjusted to 0.5 mTorr. The sputtering power is 50W, and the SnO after deposition is 30nm 2 film;

[0037] Ar and O 2 The purity is above 99.99%;

[0038] (3) Pump the vacuum of the magnetron sputtering system to 5.0×10 -5 Torr. 60 sccm of argon gas was introduced, and the pressure was adjusted ...

Embodiment 3

[0041] (1) SnO 2 The target and Cu target are loaded into the magnetron sputtering chamber; SnO 2 SnO in target 2 The purity of Cu is 99.5%; the purity of Cu in the Cu target is 99.99%;

[0042] Then, the quartz substrate was ultrasonically cleaned with acetone, absolute ethanol and deionized water, dried with high-purity nitrogen, and placed in a magnetron sputtering chamber; the distance between the target and the quartz substrate was 60 mm.

[0043] (2) Pump the background vacuum of the magnetron sputtering system to 6.0×10 -6 Torr. 60 sccm of argon gas and 4 sccm of oxygen gas (the ratio of argon to oxygen is 15:1) were introduced, and the total sputtering gas pressure was adjusted to 2 mTorr. The sputtering power is 150W, and the SnO after deposition is 30nm 2 film;

[0044] Ar and O 2 The purity is above 99.99%;

[0045] (3) Pump the vacuum of the magnetron sputtering system to 6.0×10 -6 Torr. 60 sccm of argon gas was introduced, and the pressure was adjusted t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com