High-performance alcohol gas sensor designed based on alcohol molecular imprinting mechanism and preparation method thereof

A gas sensor, molecular imprinting technology, applied in the direction of material resistance, can solve the problems of sensor device sensing performance, ignoring the effective film formation of nanomaterials, etc., to ensure stability and effectiveness, and ensure uniform void structure and conductivity. , the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

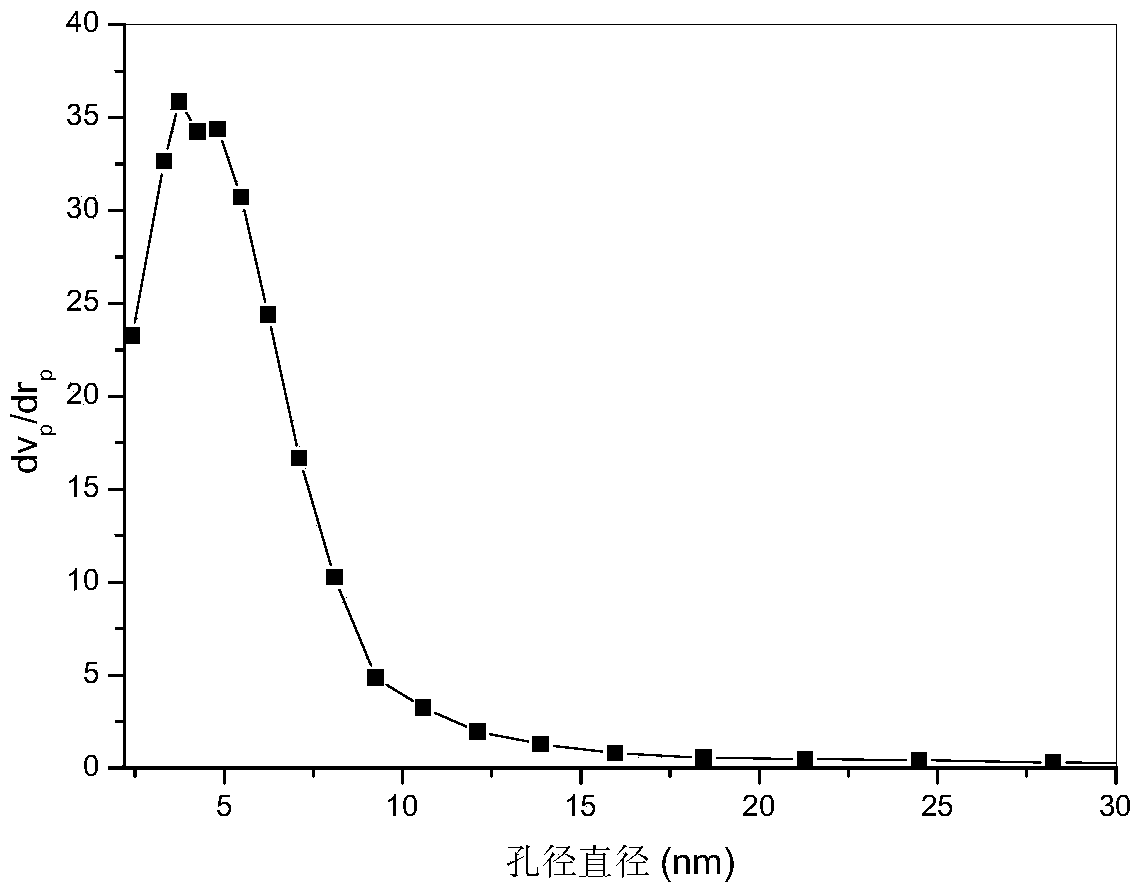

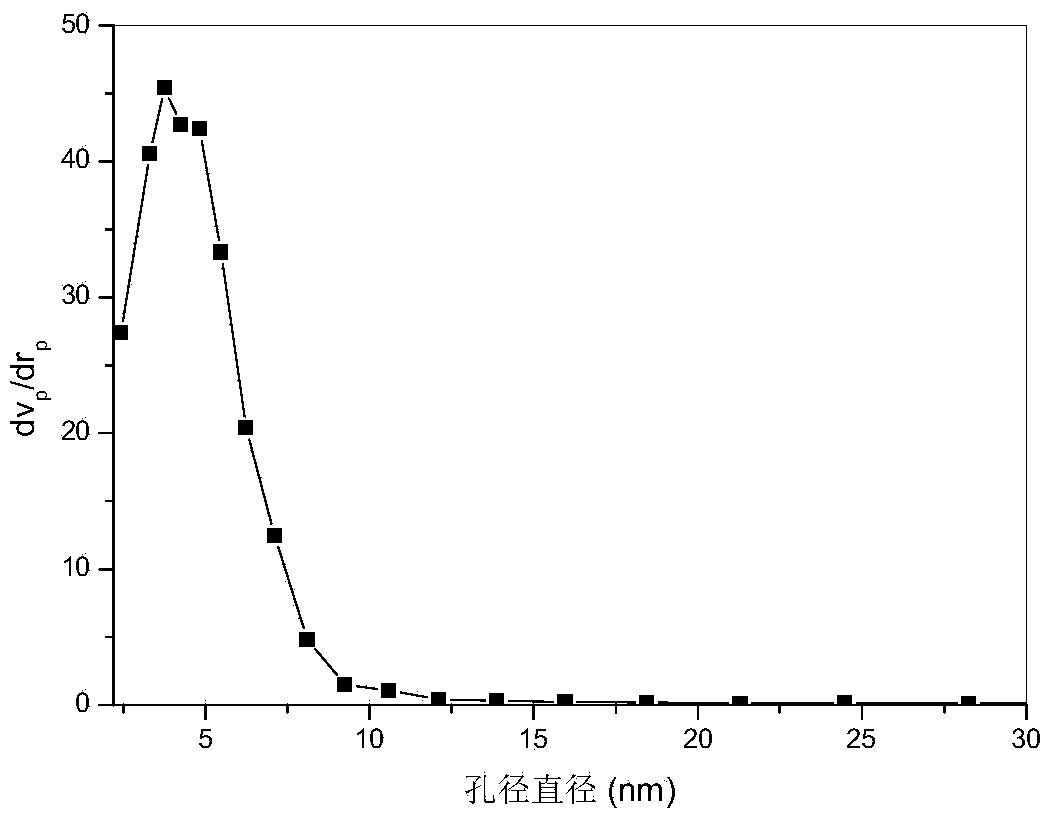

[0032] Material synthesis: SnO with medium pore size was obtained by hydrothermal method with and without alcohol addition 2 Nanomaterials E and W.

[0033] E: 1.5 grams of stannous chloride dihydrate (SnCl 2 2H 2 O) Dissolve in 50 ml of aqueous solution, add 20 ml of ethanol to mix, then perform magnetic stirring for 1 hour. Add 0.5 milliliters of hydrochloric acid (38% aqueous solution) in the obtained white suspension, fully stir 1 hour at room temperature, until the solution becomes clear; Keep at 120°C for 24 hours; after the hydrothermal method is fully reacted, cool naturally, and collect the yellow precipitate by centrifugation; wash the precipitate with deionized water for 3 times, and dry it in air at 60°C; The obtained primary particles were calcined in the air at a temperature of 350°C for 2 hours, and finally white medium-sized SnO particles were obtained. 2 nanomaterials.

[0034] W: 1.5 grams of stannous chloride dihydrate (SnCl 2 2H 2 O) dissolved in 70 ...

Embodiment 2

[0050] 1.5 g of stannous chloride dihydrate (SnCl 2 2H 2 O) be dissolved in the aqueous solution of 40 milliliters, add 20 milliliters of alcohols and mix, carry out magnetic stirring then, add hydrochloric acid (38% aqueous solution) in the obtained white suspension, fully stir at room temperature, until the solution becomes clear; The solution was sealed and heated to 140°C in a hydrothermal kettle, and kept for 20 hours; after the hydrothermal method was fully reacted, it was cooled naturally, and the yellow precipitate was collected by centrifugation; the precipitate was washed with water and dried; the obtained primary particles were , calcined in air at 300°C for 3 hours, and finally white medium-sized SnO 2 nanomaterials.

[0051] Take 0.15 ml of alcohol, with 0.3 g of SnO 2 The nanomaterials are mixed, prepared into a paste, and evenly coated on the ceramic tube with a thickness of 110 μm to make a sensor.

[0052] After characterization, the sensor SnO 2 Nano SnO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com