Mask dust collection device

A technology of dust removal device and mask plate, which is applied in the field of integrated circuit manufacturing, can solve the problems of reduced dust removal efficiency, secondary pollution, and increased nitrogen for purging, so as to achieve the effects of improving dust removal efficiency, good cleaning effect, and strengthening removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

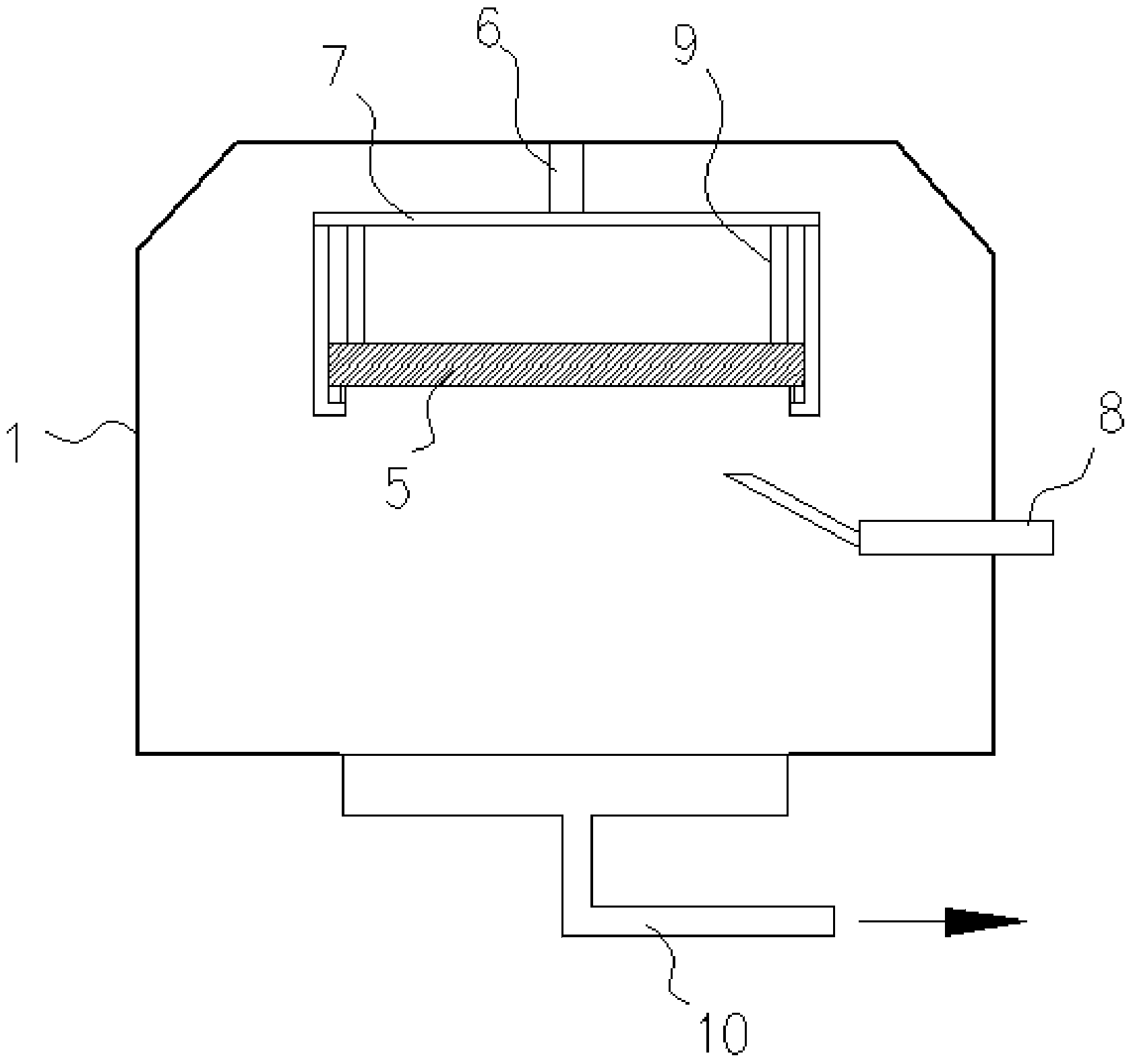

[0029] Attached below Figure 3-5 , the specific embodiment of the present invention will be further described in detail.

[0030] It should be noted that, in the following embodiments, a common square mask with a side length of 6 inches is taken as an example for illustration.

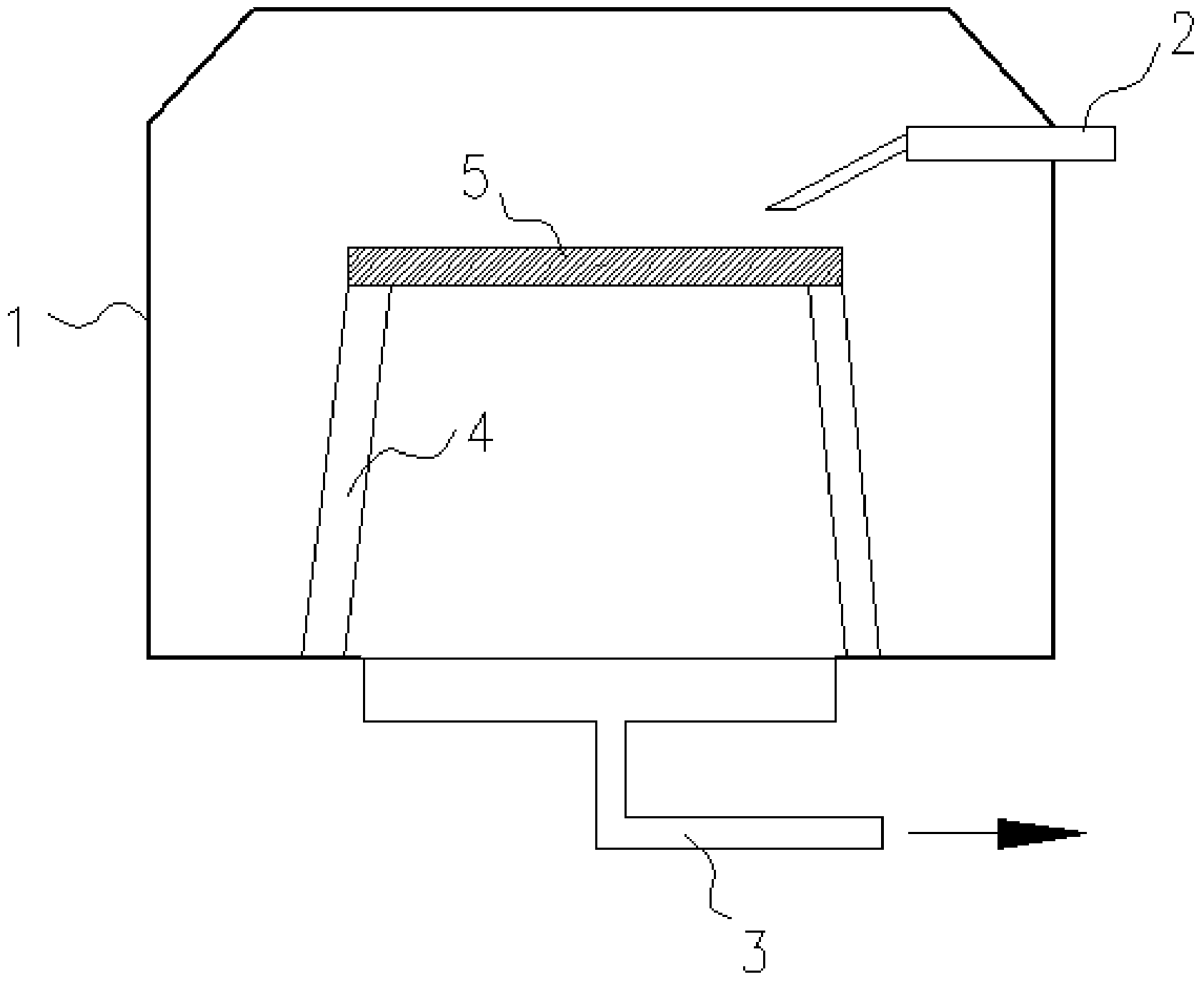

[0031] see image 3 , image 3 It is a schematic diagram of cleaning and purging the surface of the suspended and rotating mask with a nitrogen nozzle in the airtight cavity in the present invention. In the embodiment of the mask dust removal device, the airtight cavity 1 and the mask set in the cavity are included. The stencil 5 fixing mechanism and the nitrogen nozzle 8 connected to the intake pipeline further adopt the following structure, and also include an air extraction pipeline 10 located below the cavity, and the mask 5 fixing mechanism is installed inside the closed cavity 1 above, including the suspension bracket 7 that horizontally clamps the mask plate 5; the nitrogen nozzle 8 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com