Negative type photosensitive

A photosensitive, siloxane technology, used in optics, optomechanical equipment, photosensitive materials for optomechanical equipment, etc. Excellent film ratio and excellent electrical insulating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

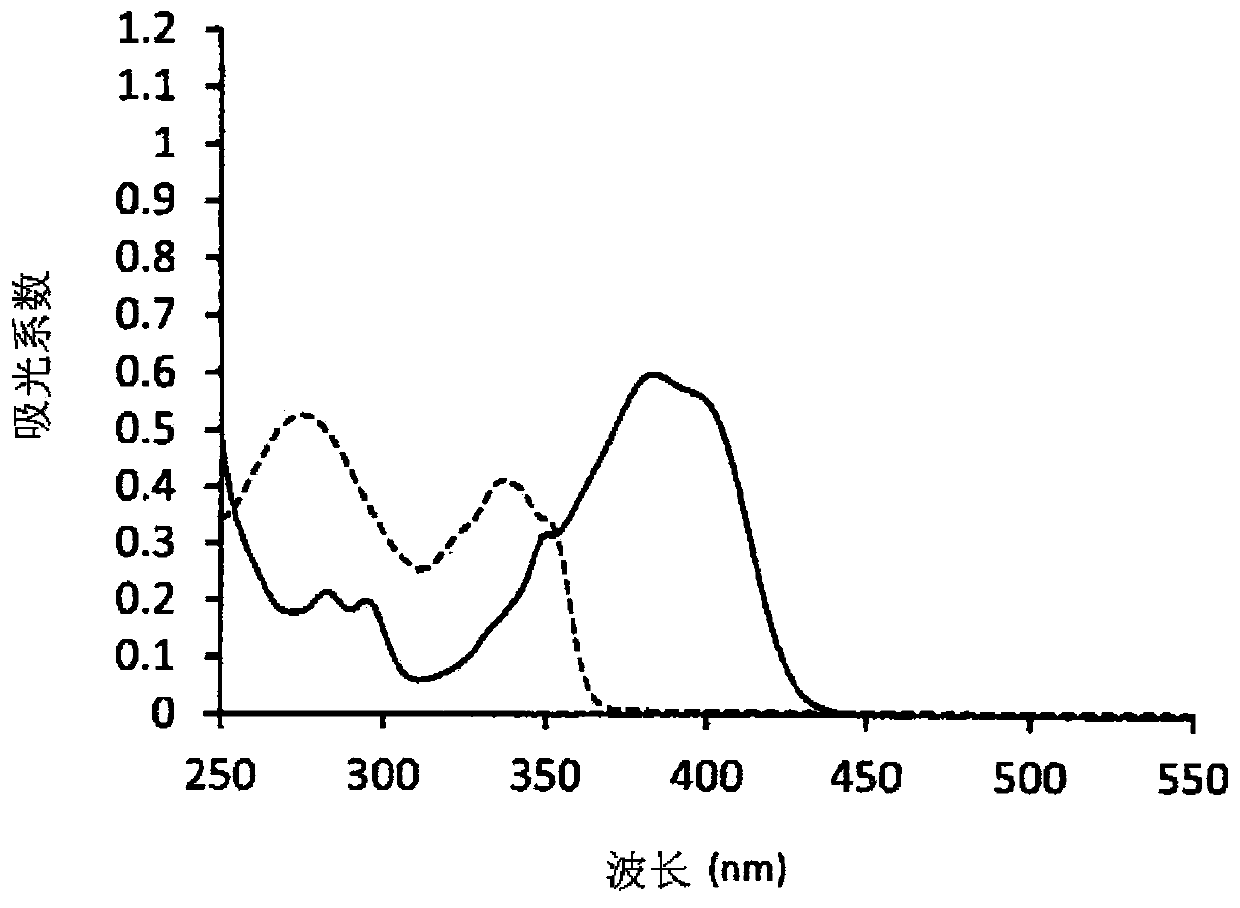

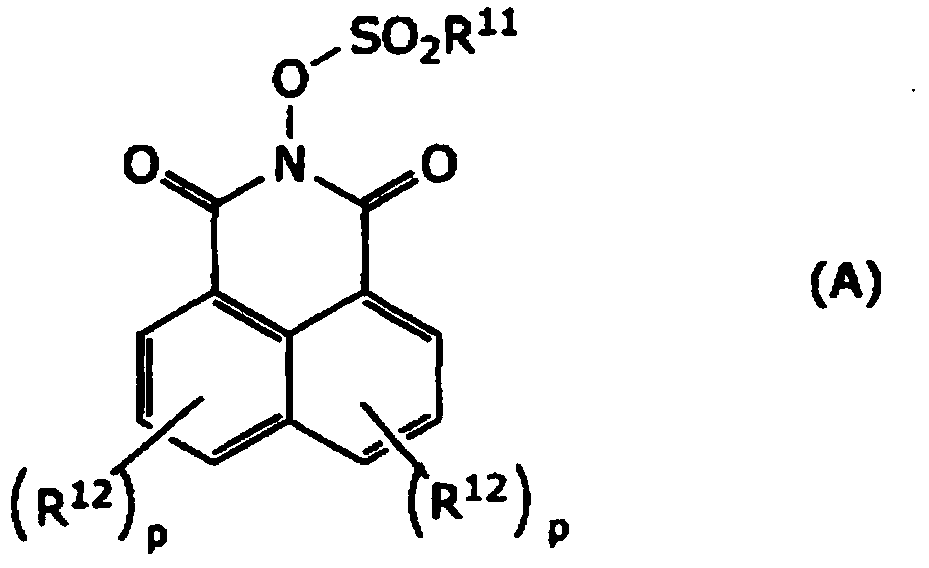

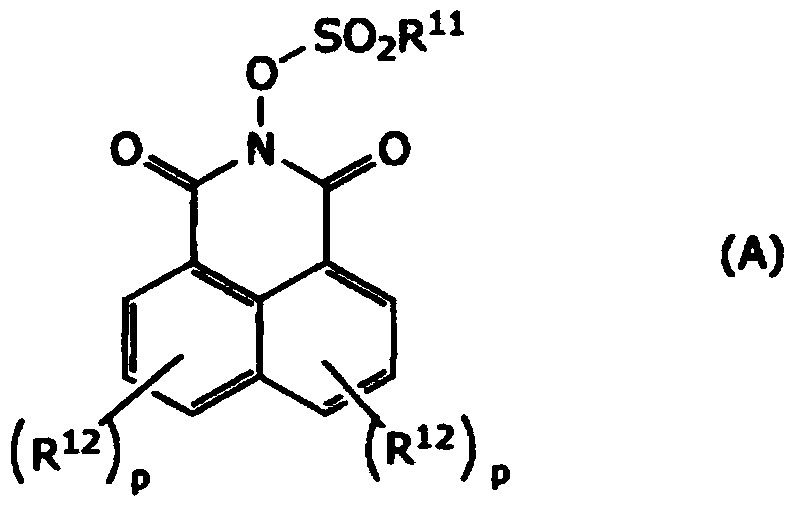

[0184] Polysiloxane (Ia-1) and polysiloxane (Ib-1) were mixed at a mixing ratio (30% by weight): (70% by weight). Regarding this polysiloxane mixture, the dissolution rate relative to 2.38% TMAH aqueous solution after prebaking is / Second. This polysiloxane mixture was prepared so as to be a 35% PGMEA solution, and 1.0% by weight of the photoacid generator represented by the aforementioned formula (A-1) was added to the polysiloxane. Moreover, 0.3 weight% of KF-53 (trade name, Shin-Etsu Chemical Co., Ltd. make) was added as surfactant with respect to polysiloxane, and the negative photosensitive silicone composition was obtained.

[0185] This photosensitive siloxane composition was applied on a silicon wafer by spin coating, and after application, it was prebaked on a hot plate at 100° C. for 90 seconds, and adjusted so as to have a film thickness of 2 μm. After prebaking, use the g, h line exposure machine of FX-604 type Stepper (trade name, manufactured by Nikon Corporat...

Embodiment 2

[0189] Except that the mixing ratio of polysiloxane (Ia-1) and polysiloxane (Ib-1) was changed to (10% by weight): (90% by weight), it was obtained in the same manner as in Example 1. Negative photosensitive silicone composition. The dissolution rate of the polysiloxane mixture relative to the 2.38% TMAH aqueous solution after pre-baking is / Second.

[0190] Instead of using this composition, changing the exposure to 50mJ / cm 2 Other than that, pattern formation and baking hardening were performed similarly to Example 1. Observation of the obtained pattern revealed that the pattern of 5 µm was maintained. However, compared with Example 1, the pattern ridge line portion is rounded at a level that is practically no problem.

Embodiment 3

[0192] Except that the mixing ratio of polysiloxane (Ia-1) and polysiloxane (Ib-1) was changed to (60% by weight): (40% by weight), it was obtained in the same manner as in Example 1. Negative photosensitive silicone composition. The dissolution rate of the polysiloxane mixture relative to the 2.38% TMAH aqueous solution after pre-baking is / Second.

[0193] Using this composition, the development time was changed to 150 seconds, and the baking curing was changed to 350°C to obtain a pattern. As a result, a 5 μm pattern without residue was maintained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com