Manufacturing method for highly-wear-resistant nanometal transparent conductive film

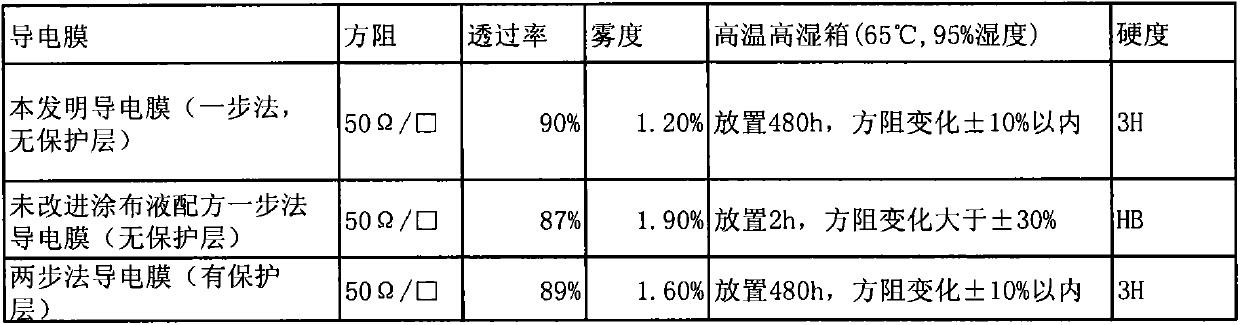

A technology of transparent conductive film and nano-metal, which is applied in the manufacture of cables/conductors, insulation of conductors/cables, circuits, etc. It can solve problems such as insufficient film hardness, poor film environmental tolerance, scratches or dents, etc. Degree and anti-scratch effect, improved coating process conditions, reduced environmental resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Flexible substrate selection polyethylene terephthalate (Polyethylene terephthalate, PET)

[0016] The formula of the conductive layer coating solution is: the nano-metal wire is selected as a nano-silver wire, the average wire length should be 20 μm, the average wire diameter should be 35nm, the content of the nano-silver wire is 0.1%, 0.34% polyvinyl alcohol, 0.2% silicon dioxide, 0.5% oxidized polyethylene wax, 0.01% polyethylene glycol octylphenyl ether. The specific preparation method is to take 250g of 0.2% nano silver wire initial suspension, the solvent of this suspension is pure water, add 215g of 0.8% polyvinyl alcohol aqueous solution to it while stirring, and finally add 10g of 10% carbon dioxide Silica hydrosol, 25g of 10% oxidized polyethylene wax hydrosol, and 0.05g of polyethylene glycol octylphenyl ether are fully stirred and then prepared.

[0017] Coat the prepared coating ink onto the substrate by spin coating, then pre-bake it in an oven at 100 deg...

Embodiment 2

[0019] Flexible substrate selection polyethylene terephthalate (Polyethylene terephthalate, PET)

[0020] The formula of the coating solution is: the nano-metal wire is selected as the nano-silver wire, the average wire length should be 20 μm, the average wire diameter should be 35 nm, the content of the nano-silver wire is 0.1%, 0.34% carboxypropyl methylcellulose, 0.2% carbon dioxide Silicone, 0.3% oxidized polyethylene wax, 0.2% polytetrafluoroethylene wax, 0.01% polyethylene glycol octylphenyl ether. The specific preparation method is to get 250g of 0.2% nano-silver wire initial suspension, the solvent of this suspension is pure water, add 0.8% carboxypropyl methylcellulose aqueous solution of 215g to it while stirring, finally add 10g of 10% silicon dioxide hydrosol, 25g of mixed hydrosol of 6% oxidized polyethylene wax and 4% polytetrafluoroethylene wax, and 0.05g of polyethylene glycol octyl phenyl ether are fully stirred and the preparation is completed.

[0021] Coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com